Automatic Salt Spray Test Chamber

Request a Quote

Description:

Salt spray testing is a corrosion testing process used to match real corrosive environments as closely as possible, and simulates those environments in order to observe the corrosion resistance of components and materials, such as automobile components, aviation devices, construction materials, coated components and electrical devices in salty and corrosive environment.

The automatic salt spray test chamber is designed according to JIS, ASTM, CNS, GB standards, and features a touch screen control.

| Model | KM-F-60C | KM-F-90C | KM-F -120C | KM-F-160C | KM-F -200C |

| Interior dimensions (L*W*H) | 600*450*400mm | 900*600*500mm | 1200*800*500mm | 1600*1000*500mm | 2000*1000*600mm |

| Exterior dimensions (L*W*H) | 1070*580*1030mm | 1380*800*1150mm | 1700*900*1210mm | 2250*1200*1250mm | 2650*1200*1350mm |

| Temperature range | 35℃-55℃ | ||||

| Temperature fluctuation | ±0.5℃ | ||||

| Temperature uniformity | ±2℃ | ||||

| Temperature precision | ±1℃ | ||||

| Testing chamber temperature | Spraying (NSS AASS)35±1℃; Spraying (CASS) 50±1℃ | ||||

| Pressure tank temperature | Spraying (NSS AASS)47±1℃; Spraying (CASS) 63±1℃ | ||||

| Salty water temperature | 35℃±1℃ | ||||

| Spraying rate | 1.0-2.0ml/80cm²/hr | ||||

| PH | NSS(6.5-7.2);AASS CASS(3.1-3.3) | ||||

| Interior volume | 108L | 270L | 480L | 800L | 1200L |

| Salty water tank volume | 10L | 15L | 20L | 20L | 30L |

| Power supply | 1 phase,AC220V,50/60Hz,20A | 3 phase,AC380V,50/60Hz,30A | |||

Sensor

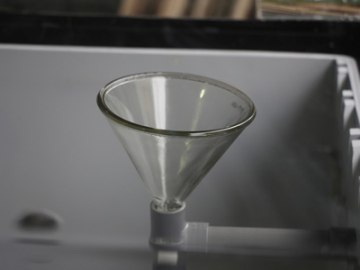

Sensor Spray device

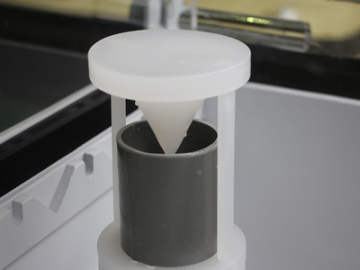

Spray device Collection hopper

Collection hopper Pressure gauge

Pressure gauge

- The interior and exterior are made of a 5-mm-thick, grade A, reinforced hard plastic plate with a smooth surface and aging and corrosion resistance.

- The cover is made of a transparent impact-resistant plate that allows researchers to observe the samples. A groove below the cover is filled with water in order to prevent salt spray leakage.

- The machine will directly heat the water using a heater installed on the bottom of the water tanks. This ensures the water heating is faster, and temperature remains even and uniform.

- Operators can observe the salt water volume using a transparent panel on the water tank, and manually add more salt water when the water level is low.

- The water circulation system is carefully designed in order to ensure normal machine operation.

- The pressure tank is made of SUS304# stainless steel, with an anodized surface in order to ensure a good corrosion resistance.

- The salt spray chamber features over pressure, over temperature, and overload protection.

Related products

Send Message

Most Recent

More

Other Products

Videos