Single Colour Sandal Injection Moulding Machine, LA120Q/LA124Q

SONC has been manufacturing injection moulding machines for years. Our portfolio encompasses footwear machines for soles or sandals. Take this single colour sandal injection moulding machine for example. It is used for producing foam or non-foam soles, sandals and slippers. The applicable materials are TPR, PVC and PUR. This injection moulding machine is equipped with 12 sets of molds, meaning that it can produce 12 pairs of shoe soles at a time.

| Item | Unit | | |

| Raw materials | TPR, PVC, PUR (blowing) | ||

| Stations | 20 | 24 | |

| Screw diameter | mm | 70 | |

| Maximum injection volume | CC | 769 | |

| Injection pressure | MPa | 70 | |

| Clamping force | Tons | 60 | |

| Yield | Pairs/hour | 80-150 | 100-200 |

| Mould space | mm | 500*240*240 | |

| Heating power | kW | 8 | |

| Total power | kW | 32.5 | |

| Dimensions | cm | 420*360*220 | 450*380*220 |

| Machine weight | Tons | 4.8 | 5.2 |

| Oil consumption | L | 600 | |

-

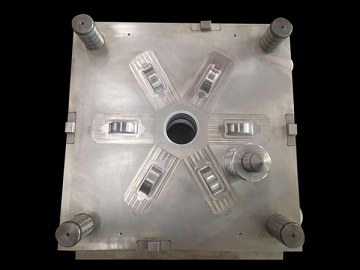

V type mould structure

-

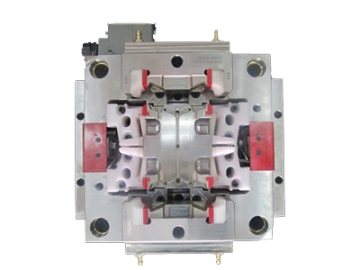

Mould manipulator

-

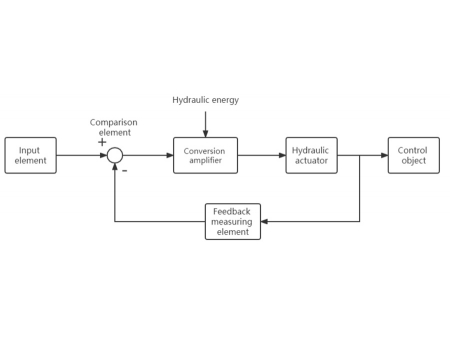

Energy-saving hydraulic servo control system

- Screw rod produced through special techniques is installed to ensure durable and efficient operation;

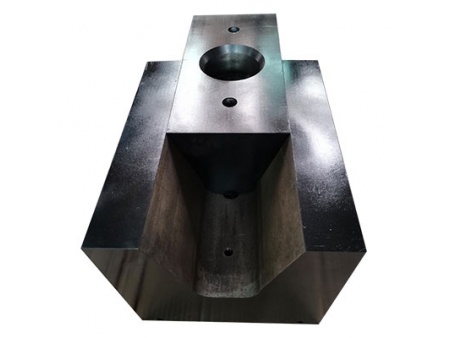

- Block cylinder is designed with special structure, providing heat insulation and leakage resistance performance;

-

Efficient air blowing system is installed to improve the quality and reduce 30% weight of the goods to be made;

-

PLC control system with industrial human-machine interface (HMI) is easy to use;

-

PLC control system

-

PLC

-

HMI interface

-

-

Multiple safety measure have been adopted;

-

Safety door with photoelectric switch

-

Safety door with photoelectric switch

-

Emergency stop button

-

Rotary table anti-lifting switch

-

-

Servo motor and automatic mould manipulator are optional, which will save energy and reduce costs;

-

Cooling tower is installed to bring down the temperature of hydraulic oil and raw materials;

-

Crusher is used to recycle used materials;

-

Vertical mixer blends materials with different colours and turn them into the same colour;

-

Air compressor will be connected to the injection moulding machine to supply air;

-

Drying system eliminates water in air so as to avoid bubbles in finished products and make better foam soles;

| Parts list | ||

| Toolbox | / | 1pc |

| Allen key | 1.5-10 | 9 sets |

| Open-end wrench | 6-24 | 8 sets |

| Phillips screwdriver (small) | / | 2pcs |

| Phillips screwdriver (large) | / | 1pc |

| Adjustable wrench | 250mm | 1pc |

| Heating ring | Ø120*80 mm | 2pcs |

| Heating ring | Ø70*50 mm | 1pc |

| Heating rod | Ø15.8*100 mm | 2pcs |

| Proximity switch | Ø 25*25mm | 1pc |

| Proximity switch | Ø 12*12mm | 1pc |

| Thermoelectric coupling | K type/5M | 2pcs |

| Oil seal | / | 2pcs |

| Plugging rod | / | 1pc |

| Plugging bushing | / | 1pc |

| Copper gasket | / | 1pc |

| Injection nozzle | / | 1pc |

| User manual | / | 1 |