Superheated Steam Jet Mill

Using superheated steam as the grinding gas, improved energy efficiency

Using superheated steam as the grinding gas, improved energy efficiency

- Superheated steam source providing high energy utilization rate and low operating cost

- Grinding particle size range D50: 0.5-10 μm

- Revolutionary innovation of dry grinding technology

- Improved energy efficiency, low carbon, energy saving and environmental protection for plants

- Applicable: bulk solid wastes such as steel slag, slag and fly ash; non-metallic minerals such as calcium carbonate, talc and quartz; new materials such as lithium carbonate, lithium iron phosphate and precipitated silica.

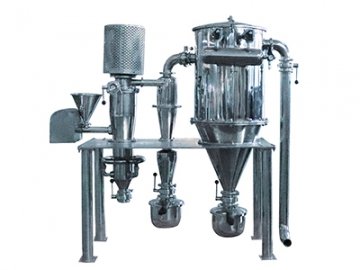

As an upgraded version of the conventional jet mill, the superheated steam jet mill utilizes a unique high-temperature mechanical sealing technology and cooling technique. High-temperature steam is used as the kinetic energy source to propel materials to collide and grind at an accelerated speed through a specially designed Laval nozzle. After being ground, the materials undergo cyclone classification, at which point a heat preservation collection system collects the qualified powders while any coarse particles fall back into the grinding chamber. The entire process is achieved without using any liquids.

- Producing nanometer-size powders under a dry process

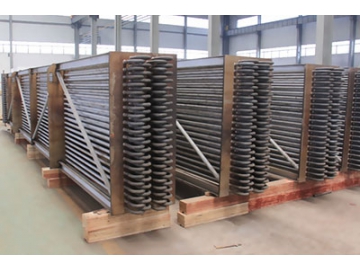

- Superheated steam source creating a working pressure between 8-40 bar and steam temperature between 230-360 ℃, which can also dry the powder with heat

- High jet velocity provides high kinetics and strong grinding force with nozzle outlet velocity up to 1020 m/s, suitable for finer powder production

- Low viscosity of steam makes it easier to obtain finer powders

- Full self-grinding of the material, ensuring product purity and wear resistance of the mill

- High speed and low dynamic viscosity increase grinding efficiency and classification accuracy while reducing over-grinding

- Good particle shape with high activity

- Classifier wheel automatically separates materials through airflow, preventing coarse particles from discharge

- Key components such as lining, classifier and nozzle are made from ceramic materials (e.g. Alumina, zirconia, or silicon carbide) for zero contact with metal during the whole grinding process

- The classifier rotor can be installed horizontally or vertically; more rotors available

- Rotor speed adjustable by frequency conversion allowing flexible particle size distribution adjustment

- Closed loop system, reducing dust and noise and creating a clean production environment

- PLC control system, easy to operate

- Can be used for superfine processing of high-viscosity products

- Motor connection via belt improves rotating speed

- Multi-stage classifier optional, allows the production of multiple particle sizes at one time

- Precise weighing control system available. ensuring product stability and consistency

- Explosion-proof design or nitrogen circulation upgrades optional, to meet ultra-fine grinding requirements for flammable, explosive or easily oxidized materials

| Parameter (S-MQL/W) | 2000 | 3000 | 4000 | 6000 | 10000 | 15000 | 20000 |

| Steam consumption (kg/h) | 1000~2000 | 1500~3000 | 2000~4000 | 3000~6000 | 6000~10000 | 10000~15000 | 15000~20000 |

| Steam pressure (bar) | 5~40 | 5~40 | 5~40 | 5~40 | 5~40 | 5~40 | 5~40 |

| Temperature (℃) | 260~360 | 260~360 | 260~360 | 260~360 | 260~360 | 260~360 | 260~360 |

| Production capacity (kg/h) | 400~1000 | 600~1500 | 800~2000 | 1200~3000 | 2000~5000 | 3000~8000 | 4000~10000 |

| Product size (D50:μm) | 2~10 | 2~12 | 2~12 | 2~14 | 2~14 | 2~16 | 2~16 |

Note: The particle size, specific gravity, hardness, and moisture of raw materials are all closely associated to the production capacity. These parameters should only be used as a reference; for more detailed information please consult our engineers.