Immersion Heated Ceramic Galvanizing Kettle

Request a Quote

- Electric immersion heated ceramic galvanizing kettle

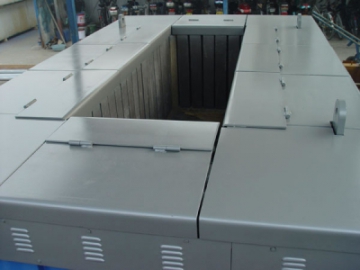

Electric immersion heated ceramic galvanizing kettle

Electric immersion heated ceramic galvanizing kettle  Gas fired immersion heated ceramic galvanizing kettle

Gas fired immersion heated ceramic galvanizing kettle  Gas fired immersion heated ceramic galvanizing kettle

Gas fired immersion heated ceramic galvanizing kettle  Plate and strip hot-dip ceramic galvanizing kettle

Plate and strip hot-dip ceramic galvanizing kettle  Plate and strip hot-dip ceramic galvanizing kettle

Plate and strip hot-dip ceramic galvanizing kettle

The immersion heated ceramic galvanizing kettle is an important hot-dip galvanizing machine in a galvanizing line. It has been widely used for the galvanizing equipment for steel wire, fastener, structural parts, malleable iron pipe, electric power fittings, steel nail, steel plate and strip, and so on. The molten zinc could reach 550℃.

Structure of the immersion heated ceramic galvanizing kettle

- As a hot-dip galvanizing kettle, it consists of kettle, immersion heating device, electronic control system, and temperature control system. Specifically, the kettle comprises with casting layer, thermal insulating layer, and heat conservation layer, as well as the steel structural frame.

- The kettle comes in a cubic structure. The top side is plane, while the heaters are mounted vertically and evenly on the inner side of the kettle. Thus the zinc temperature can stay identical, and the operation and maintenance are both quite easy. You can get higher productivity and safety.

- The electronic control system and temperature control system of the immersion heated ceramic galvanizing kettle come with a temperature display for both the heater and zinc fluid. The heaters can resist the corrosion of the hot zinc. An anti-corrosive thermoelectric couple is used for the zinc temperature detection. Due to the direct contact with zinc, temperature detection is quite accurate. Thus the automatic temperature control and stable zinc temperature can be achieved.

- The steel frame for the kettle structure of the immersion heated ceramic galvanizing kettle is welded by quality steel. The welding seam and welding spot are under rigidly quality control so that the strength of this galvanizing equipment can be guaranteed. During the long-distance transportation, the machine won't get damaged in any way. The surface has been treated by efficient anti-rust techniques, giving the zinc electroplating kit great appearance and much longer service life.

Feature of the immersion heated ceramic galvanizing kettle

- The heating devices are made of rare earth alloy or composite ceramic, so it features great corrosion (from zinc) resistance, high temperature resistance, good heat conductivity, high strength, desirable anti-impacting performance, excellent anti-wear ability, and so on.

- The thermal stability is great, giving the kettle at least ten years of service life.

- Our immersion heated ceramic galvanizing kettle has a high thermal efficiency of 80%~90%, saving about 30% energy in comparison to iron kettle with external heating devices.

- The kettle body consists of three layers of thermal insulating materials, leading to excellent heat conservation performance. So the external temperature of the equipment is greatly improved. This technique has been granted with utility model patent.

- The galvanizing kettle can melt zinc conveniently and quickly due to the adoption of internal heating devices. Limited cadmia and zinc ash will be produced.

- The kettle doesn't produce any cadmia, so the zinc consumption is significantly (10-15%) reduced in comparison with that of a iron kettle.

Regular specification of the immersion heated ceramic galvanizing kettle (custom products are available)

Galvanizing kettle with ceramic immersion heater

| No. | Effective internal size(mm) | Zinc capacity(ton) | Heater quantity(set) | Power of each Heater(kW) | Total power(kW) | ||

| 1 | 1100 | 600 | 700 | 3.3 | 18 | 3 | 54 |

| 2 | 2000 | 600 | 700 | 6 | 30 | 3 | 90 |

| 3 | 2500 | 650 | 700 | 8 | 30 | 3 | 90 |

| 4 | 2530 | 800 | 900 | 13 | 36 | 4 | 144 |

| 5 | 3500 | 800 | 900 | 18 | 48 | 4 | 192 |

| 6 | 4000 | 800 | 900 | 20 | 54 | 4 | 216 |

| 7 | 4000 | 940 | 1100 | 29 | 66 | 5 | 330 |

| 8 | 6000 | 940 | 1100 | 43 | 96 | 5 | 480 |

| 9 | 7000 | 940 | 1100 | 50 | 108 | 5 | 540 |

Galvanizing kettle with alloy immersion heater

| No. | Effective internal size(mm) | Zinc capacity(ton) | Heater quantity(set) | Power of each Heater(kW) | Total power(kW) | ||

| 1 | 2200 | 600 | 800 | 11 | 12 | 10 | 120 |

| 2 | 2800 | 600 | 800 | 14 | 15 | 10 | 150 |

| 3 | 3300 | 600 | 800 | 16 | 18 | 10 | 180 |

| 4 | 3800 | 600 | 800 | 18 | 21 | 10 | 210 |

| 5 | 4300 | 600 | 800 | 20 | 24 | 10 | 240 |

Related products

Send Message

Most Recent

More

Other Products

Videos