Fastener/Electrical Fitting Galvanizing Line

Our fastener/electrical fitting galvanizing line can be used as either an excellent fastener galvanizing equipmentor an electrical fitting galvanizing equipment. It has been widely recognized by our customers worldwide. Contact us if you have any questions on our zinc plating line.

Parameters of the fastener/electrical fitting galvanizing line

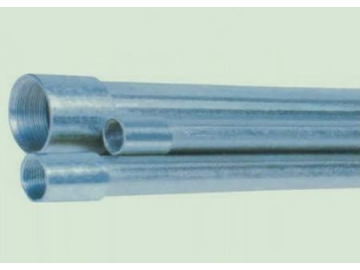

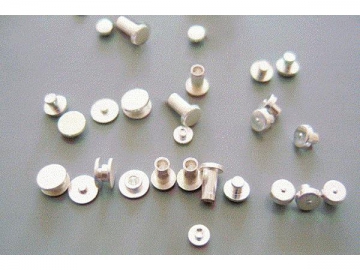

- Target workpiece: fastener and electric fitting

- Galvanizing temperature: 440℃~540℃

- Galvanizing solution: pure zinc

- Coating thickness: 20μ~100μ

- Energy: electricity

- Coating standard: GB/T2314-2008, GB-T13912-2002

Process flow of the fastener/electrical fitting galvanizing line

Workpiece preparation – alkaline degreasing – water rinse – acidic de-rusting – water rinsing – flux solution – drying – hot-dip galvanization – zinc residue removing – water cooling – passivation – product inspection – finishing

Main machine of the fastener/electrical fitting galvanizing line

Ring shaped hanging equipment, enclosed pre-treatment equipment, crawler type semi-automatic drying furnace, immersion heated ceramic galvanizing kettle, filter bag dust collecting device, pneumatic zinc residue removing machine, crawler type and cooling device

Equipment feature

The pretreatment bath comes with steel structural frame and internal PPH plate lining. Thus the anticorrosive performance and high strength can be both achieved. A steam heat exchanger or PTFE electric heating device is available for the degreasing bath and flux solution bath.

In our fastener/electrical fitting galvanizing line, the APVC plate is used to enclose the pretreatment bath. The acid fume will be extracted from the enclosed room to the scrubber. The acid fume will be collected and absorbed in the acid fume scrubber by sodium hydroxide solution. As high as 50% hydrochloric acid can be absorbed. The hydrochloric acid concentration in the treated exhaust is only 1.25mg/m3, while the exhaust flow rate is 0.05kg/h, meeting the related environmental protection standard.

Manual pre-treatment bath

Manual pre-treatment bath  Automated pre-treatment bath

Automated pre-treatment bath

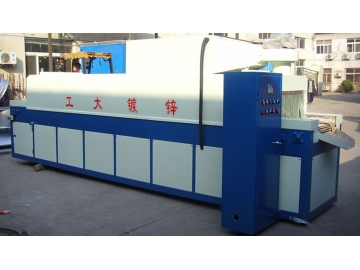

The drying furnace of the fastener/electrical fitting galvanizing line comes with a semi-automated belt conveying device, whose conveying speed can be adjusted between 0.15m/min and 1.5m/min steplessly. The electric drying furnace has a temperature controlling device (with a digital display) for the automated temperature control. The temperature is adjustable between 100℃~180℃, while the hot air circulation fan is adopted to dry the workpiece. The drying furnace comes with double-layer heat insulation structure. The 316L steel plate is used as the lining inside the furnace, preventing the furnace from the corrosion by the flux solution solution. Thus the service life of the furnace can be largely enhanced.

Drying furnace

Drying furnaceThe galvanizing furnace of our fastener/electrical fitting galvanizing line comes with an immersion heated ceramic galvanizing kettle. The immersion heating technique features high heating speed, low energy consumption, high efficiency, stable working performance, and long service life. Specifically, the service life could be more than 10 years. The adoption of ceramic galvanizing kettle could save you 10% ~ 15% zinc in comparison to the iron kettle. The body of the ceramic galvanizing kettle has three layers of heat conservation structure, making the outside temperature lower than 50℃. Thus the working environment for workers is greatly improved.

As one of our patented products, this alloy heater for galvanizing can resist the corrosion of molten zinc for 3 to 6 years, and has great high temperature resistance, high toughness and hardness, good heat conductivity, great thermal efficiency (above 92%), low electric resistance, and low dilatation coefficient. The excellent performance of our fastener/electrical fitting galvanizing line in hot-dip galvanizing of fasteners has been recognized by not only the domestic customers but also overseas users in the United States, Canada, India, and so on.

Gas heated ceramic galvanizing kettle

Gas heated ceramic galvanizing kettle  Electric heated ceramic galvanizing kettle

Electric heated ceramic galvanizing kettle  Manual hot-dip galvanizing

Manual hot-dip galvanizing  Automatic hot-dip galvanizing

Automatic hot-dip galvanizing

The zinc removing machine is a key facility for the fastener/electrical fitting galvanizing line in terms of coating thickness controlling. The machine is quite user-friendly. Its cover is controlled by a pneumatic device, making the operational labor intensity greatly reduced. An electromagnetic brake is adopted, and the braking duration is between 1.5~2s.

Semi-automatic zinc removing machine

Semi-automatic zinc removing machine  Manual zinc removing machine

Manual zinc removing machine

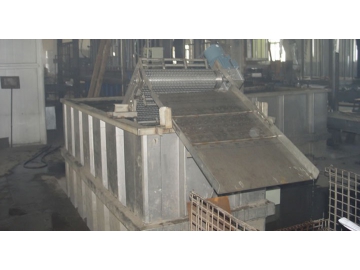

The cooling equipment comes with a semi-automatic crawler type conveying device. The crawler can convey the zinc-removed fasteners to the water cooling bath and passivation bath. Thus the labor cost can be lowered and the technical accuracy can be guaranteed.

Automated water cooling and passivation

Automated water cooling and passivation Inspection and assembling

Inspection and assembling