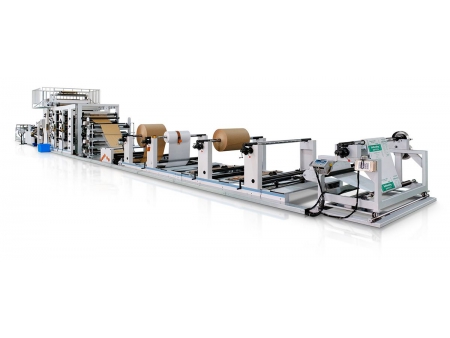

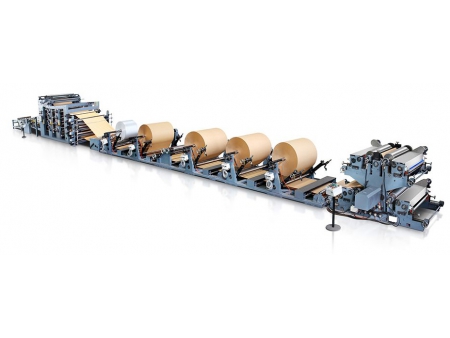

Valve Sack Bottomer (Both End Pasted), HD8916

HD8916 valve sack bottomer is a paper bag tube conveying machine turning tubes into bags, available in both-end-pasted or one-end pasted ways which can be done in one pass. Customers can choose double-end interior and exterior reinforcement units.

- Ultrasonic sealing paper valve bag

- Hot-melt glue sealing paper valve bag

- Kraft paper valve bag with thumb notch

- Film laminated paper valve bag

| Weight | 34.5 t |

| Size (High Configuration) | 27.2×5.6×2.1m |

| Bag length | 370-770mm |

| Bag width | 350-550mm |

| Bottom width | 90-150mm |

| Bag center distance | 280-620mm |

| Productivity | 80-100 sacks/min |

- Feeding

- Positioning and perforation

- Vacuum opening and bottom forming

- Bottom closing & gluing unit

- Forming unit

- Flipping

- Valve bag discharging unit

- Flat valve making

- Tube valve making

- Interior reinforcement mechanism

- Exteiror reinforcement mechanism

- Compacting & counting unit

-

Feeding unit

The feeding unit uses rotary rollers to feed. Small rollers rotate around big ones and rotate reversely to achieve suction feeding. A big roller rotates once feed 8 paper bag tubes.

Rotating vaccum suction feeding is the most convenient way, which is conceived as reliable and stable. -

Positioning & perforation unit

This positioning and perforation mechanism is equipped with positioning unit, ensuring high precision of paper bag tubes positioning.

The unit of our valve sack bottomer is equipped with inclined indentation function, allowing you to adjust the indentation’s position without shut down the machine or adjusting the speed.

It has the perforation function to produce vent holes throughout the entire bag, mainly applied to cement bag production.

This mechanism also supports flush cut, which is mainly applied to flush cut paper bag tubes, meaning that it cut the bag twice on both ends. -

Vacuum opening & bottom forming unit

The paper bag tubes will be opened by means of the vacuum opening unit of our valve sack bottomer, so that the handling unit can get inside the tube.

The handling unit opens the paper bag tube, adjusting it from front to rear. Therefore, the block bottom of paper bag is properly formed, without tilting.

This mechanism can also flatten the bags, assisting the handling unit to form and compact the paper valve bag bottom. -

Flap valve making unit

Flap valve making unit guides the rolls to pass through the right paper path with the help of the web guide. Through traction, cutting and clamping, the paper travels in rotation via the paper clamping roller, to the glue wheel and then be pasted on paper bag tubes. The electric controlling system supervises the procedure, for instance, if no bags were found in the right place, then the system will release the clamped paper, then the paper won't pass through the glue wheel but another path. Meanwhile, the glue wheel separates from the clamping roller.

Users can adjust the flap valve making mechanism to attach internal valve port or external valve port. The differential adjustment device allows operator to adjust the attachment positioning without shutting down the machine.

Specifications adjustment is also available via the screen, you can set up different valve paper length. -

Sleeve valve making

Valve paper is guided by web guiding unit from the roll stand to pass through the right place. Through traction, cutting and clamping, the paper travels in rotation via the clamping roller, to the glue wheel and then be pasted on paper bag tubes.

The electric controlling system supervises the procedure, for instance, if no bags were found in the right place, then the system will release the clamped paper, and the paper will take another path. Meanwhile, the glue wheel separates from the clamping roller. The sleeve valve making unit is equipped with differential adjusting device for the valve sack bottomer, allowing you to adjust paper withour shutting down the machine.

Customers can paste internal and external valve, sleeve valves and sacks with thumb notch. If needed, you can also adjust the parameters on screen and set up different valve paper lengths. -

Interior reinforcement mechanism

In the interior reinforcement mechanism, the reinforcing paper roll is guided through the web guide into the set path. The paper passes through traction unit, cutting unit and clamping roller. Then it travels in rotation by the clamping roller, to the glue wheel and then be pasted on paper sack tubes. The electric controlling system supervises the process, for instance, if no bags were found in the set place, then the system will release the clamped paper, meaning that the paper won't pass through the set path. Meanwhile, the glue wheel is separated from the clamping roller.

This mechanism of valve sack bottomer is equipped with differential adjusting device, allowing you to adjust the positioning of paper without shutting down the machine. Customers can also adjust the parameters on the screen and set up lengths for reinforcing paper strip. -

Bottom closing & gluing unit

The bottom closing and gluing unit has indentation device for paper sack bottoms to assisting its shaping and a big glue wheel with which customers can change the shape of glue plates according to different specifications and requirements of paper bags. Then you can adhere the glue plate to the set place on the big glue wheel.

Equipped with glue melt system, the mechanism is able to detect whether there are paper sack tubes in position or not. It can also tell if the bottoms of paper sack tubes are normal. When paper sack tubes shortage and abnormality of bottoms are detected, the glue melt system will stop operation. -

Forming unit

The forming unit is comprised of supporting panels, among which the inward panels support the bottom paper and outwards panels serve as a guide for the bottom paper to form into rectangular-shaped bottoms. Then the compactor will make the bottoms more durable.

The panel size can be adjusted according to the production needs of different bottom size. -

Exteiror reinforcement mechanism

In the exterior reinforcement mechanism, the reinforcing paper roll is guided through the web guide into the set path. Through traction unit, cutting unit and clamping roller, the paper travels in rotation by the clamping roller, to the glue wheel and then be pasted on paper sack tubes. The electric controlling system supervises the procedure, for instance, if no bags were found in the set place, then the system will release the clamped paper, meaning that the paper won't pass through the glue wheel but another path. Meanwhile, the glue wheel is separated from the clamping roller.

This mechanism of our valve sack bottomer is equipped with differential adjusting device, allowing operator to adjust the positioning of paper without shutting down the machine.

It is equipped with servo driven paper feeding unit, including two tracing modes: color tracing cutting mode and cut-to-length mode. You can switch the modes on the touchscreen easily.

Parameters can be easily adjusted via the screen, through which customers can set up different reinforcing paper strip lengths. -

Flipping

The two ends of bottomed paper sacks stay vertical.

-

Compacting & counting unit

Through the flipping unit, paper sacks are sent at a lower speed while passing the compacting belt. The compacting effect will be more obvious after bags are piled up. The unit is equipped with counting device, you can preset paper bag number in the system.

The compacting and counting unit of valve sack bottomer is equipped with vacuum absorbing and accelerating separating device, which is used to separate piled-up paper bags when the bags have reached certain amount set by the system. -

Valve bag discharging unit

Through the compacting and counting unit, paper sacks reach the valve bag discharging unit. When the paper bag number reaches certain line, the compacted sacks will be sent to the piling-up area. The valve of piling-up area then opens and the belt conveyor starts to convey the paper sacks. Piled-up paper sacks are sent to the valve bag discharging area, where workers will be responsible for stacking.

- Kraft valve sack

- Kraft valve sack

- Kraft valve sack

- Kraft valve sack

Youniker offers both complete line and individual equipment including valve sack tubers and bottomers to satisfy your paper bag production needs.