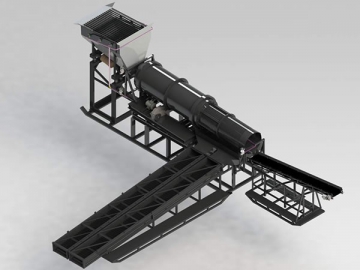

Rotary Scrubber

Rotary scrubber is primarily used to remove the mud from mud-bearing iron, manganese, limestone, and tin ore before ore beneficiation. Our scrubber is one of the most effective solutions for washing of large-sized ore at present. Generally, washing of large lump ore is very difficult. However, our rotary scrubber is able to finish stirring, washing, separating and desliming of large lump ore. It ensures high washing efficiency of 98%.

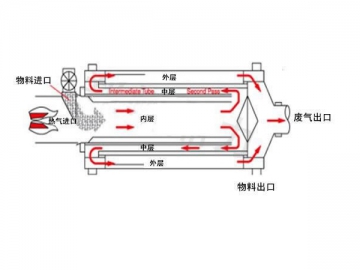

The scrubber is supported by four trunnion rollers at either end. The cylindrical drum rotates at a low speed driven by a motor and a reducer. First, the feeding machine will brings the ore containing mud and fine aggregate to the drum through the feed inlet. Then the ore will be lifted, tossed and stirred by the stirring device with specific angle in the interior of the drum. During moving back and forth repeatedly from the feed end to the discharge end, the ore will be cleaned continuously by the forward and backward high pressure water columns. The cleaned ore will be delivered to the finished product pile through the discharge chute after removal of sewage, which flows out through the sewage device at the discharge outlet. The mud-bearing sewage enters the three-level settling pond for sediment so that it can be recycled for further ore washing.

Characteristics

1. Our rotary scrubber is capable of dealing with large-sized aggregated stones. It is suitable for desliming of artificial aggregates with size smaller than 80mm.

2. Finished product of our scrubber contains less than 0.5 percent of mud and less than 2 percent of water.

3. Besides belt conveyor and stacking machine for the finished product, all components are integrated in a framework, which contributes to high integrality of the scrubber and ensures enough space for maintenance and inspection

4. With high integrality, the rotary scrubber can be deposited in the construction site and also can be easily transported between different sites.

5. The core washing system in the rotary scrubber is designed with the same principle as mixing principle in a mixer. The screw blades inside of the rotary drum constantly tumble and shove the raw materials. Moreover, raw materials will grind to each other. As a result, high stirring efficiency is achieved, which is beneficial to further washing process, which means that our scrubber can ensure high reliability.

6. The storage hopper on the rotary scrubber is as large as 8m3, which contributes to proper feeding time of the stone scrubber and the primary equipment such as mixing station. Therefore, the loading machine doesn’t have to frequently move back and forth between different loading spots and the raw materials pile. The width of the hopper is larger than 3 meters, which facilities feeding of raw materials with the loading machine, thereby lowering labor intensity. In a word, the scrubber features high economic efficiency and high usability.

7. The rotary scrubber is also fitted with a water tank which is used to recycle sewage water, automatically replenish clean water, rewash finished product upon discharging and remove sludge.

8. Finished aggregated stones can be directly put into a warehouse or delivered in the hopper of a following device like a dosing machine for further processing.

| Model | Barrel Diamter × Length | Maximum Feed Size | Capacity | Barrel Rotating Speed | Power | Weight |

| Φ1.0×3.0 | 50 | 30 ~ 70 | 30 | 30 | 10800 | |

| Φ1.5×3.0 | 50 | 70 ~ 140 | 30 | 55 | 17800 | |

| Φ1.8×3.6 | 80 | 120 ~ 200 | 25 | 75 | 24700 | |

| Φ2.1×4.5 | 150 | 180 ~ 250 | 21 | 110 | 32618 | |

| Φ2.4×5.0 | 200 | 230 ~ 300 | 18 | 160 | 48700 | |

| Φ2.7×6.0 | 250 | 280 ~ 420 | 16 | 220 | 67200 |