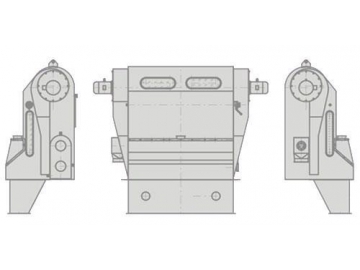

Circulating Air Separator

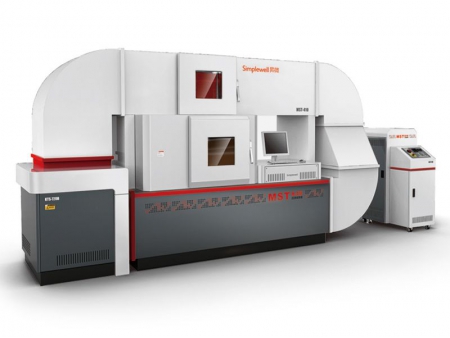

The TFXH series circulating air separator is especially designed for the separation of low-density particles (hull, dust, etc.) from grains such as wheat, barley, maize, oilseed and others. It is commonly seen in grain depots, flour mills, rice mills, grain distilleries, oil factories, maize processing plants, feed manufacturing factories, etc. Moreover, this machine can be applied both as a stand-alone machine and in combination with vibratory separator, rotary separator or wheat scourer.

| Model | Throughput (t/h) | Power (kW) | Overall dimensions (L×W×H, mm) |

| | 16 | 2.2 0.75 | 1670×1000×1680 |

| | 24 | 2.2×2 0.75 | 2556×1000×1680 |

| | 32 | 2.2×2 0.75 | 3100×1000×1680 |

1. Reasonable Design

Our product adopts the enclosed design, and the feed mechanism is enclosed outside and opened inside. And the axial pressure door is used to remove light impurities. So, mechanical failure at the feed place is avoided, and the screw conveyor won't be blocked by light impurities.

2. Excellent Performance

Our circulating air separator makes use of a large dust settling chamber to significantly enhance the separation result.

3. Dust-Free Running

This equipment possesses outstanding tightness, and the connection parts are handled by sealing strip. As a result, dust separated from the grains won't spread into the surrounding environment.

4. All steel used is WISCO or Baosteel cold plate products (or products of equivalent quality); panels at both sides are 3mm cold-rolled steel plates, the blade of fan impeller are 3mm/NM400 wear-resistant plates, the rest of the main body part are cold-rolling or hot-rolling steel plate that is no less than 2mm.

5. The deceleration motors are Xingguang products, the motor protection level is IP55, and the insulation grade is F.

6. The connection hole of the motor junction box needs to be equipped with a galvanized iron cable sealing head.

7. The bearings are Harbin bearings;

8. The wind motors are Siemens motors (Beide motors). The protection grade of the motor is IP55, and the grade of insulation is F

9. Steel used are treated with rust-removal, pickling, phosphating, painting or stoving varnish.