Spray Dryer Paraformaldehyde Plant

Request a Quote

Utilizing a spray dryer process, the formaldehyde content can be controlled by up to 92~96%, with porosity, good water solubility and short depolymerization time. Using our production technology, we attach great importance to the research and development of formaldehyde condensation systems, the spraying tower design, the spraying head design and catalyst selection. The continuous circulation use is the most important characteristic, and the low concentration of formaldehyde can be collected and reused to produce a methylal solution with higher value.

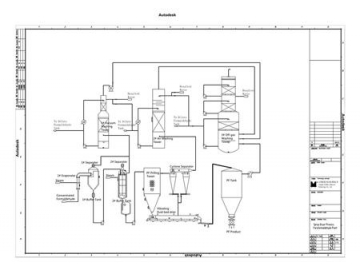

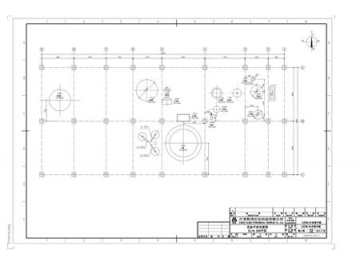

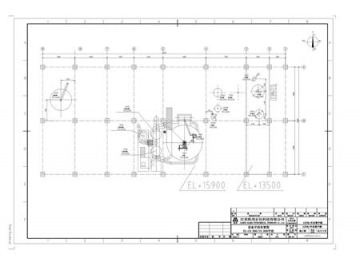

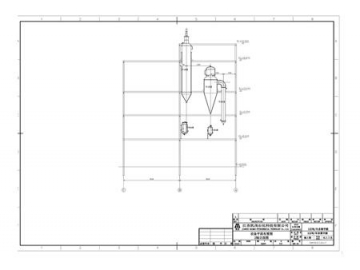

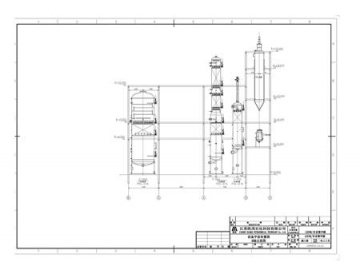

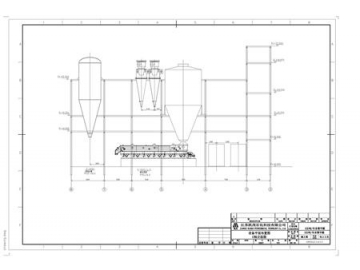

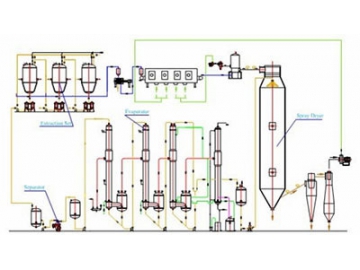

Flow chart

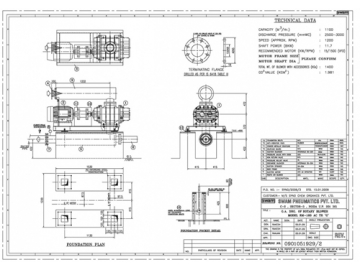

Paraformaldehyde Processing Equipment

- The first- efficiency evaporator

- The second-efficiency separator

- Separator

- Buffer tank

- Vacuum washing tower

- Desalted water

- Air washing tower

- Vibrating fluid-bed drier

- Cyclone Separator

- Off-gas washing Tower

Advantages

- The theory for first-efficiency evaporator is climbing film evaporation.

- The second-efficiency separator theory is the falling film evaporation.

- The off gas from the second-efficiency separator comes is a 1# absorber for absorption, creating a diluted formaldehyde solution.

Paraformaldehyde Production Process

- Concentrate 50%-55% formaldehyde solution.

- Further concentrate the formaldehyde solution to 85%.

- Condense and dewater the 85% high concentration formaldehyde solution.

- The solid paraformaldehyde from the spraying cooling tower and cyclone dust collector comes into fluidized-bed drying for the second drying.

- Off gas absorption.

Note: If you want to know more about the production process in detail, please contact us.

The Specification of Paraformaldehyde

| Item | Index | Remarks |

| Paraformaldehyde content | 92-96% w/w | Normally 92% |

| Formic acid | <0.03% | |

| Melting range | 120-170℃ | |

| Ash content | <100ppm | |

| Appearance | White powder | |

| Methanol content | <1wt% | |

| Free water | <8wt% | |

| Iron content | <2ppm |

Raw material specification

| Item | Specification |

| Formaldehyde | 50.0%wt |

| Desalted water | Conductivity no more than 10μs/cm,P≥0.3mpa |

| Steam | 0.4MPa |

| Steam | 0.8MPa |

| Electricity | 380V |

| Circulating water | 30~38℃ ,0.25mpa |

| Cooling water | -1~3℃ ,0.25mpa |

| Instrumental air | 0.7MPa |

| Nitrogen | 0.7MPa |

| Item | Consumption quota | Remarks |

| Raw material and auxiliary material | ||

| Formaldehyde(50%) | 2.665T/T | |

| Dilute formaldehyde(19%~24%) | -2.2T/T | By-product dilute formaldehyde |

| Utilities | ||

| Circulating water t≤32℃,△t=10℃ | 288T/T | |

| Dynamic electricity(380V) | 280kWh/T | |

| low pressure steam P=0.4MPa(G) | 1.30T/T | |

| low pressure steam P=0.8MPa(G) | 0.90T/T | |

| cooling water-2℃,△t=5℃ | 120T/T | |

| soft water | 0.2T/T | |

| instrumental air P=0.7MPa(G)) | 48Nm3/T | |

| Nitrogen P=0.7MPa(G) | 99Nm3/T | |

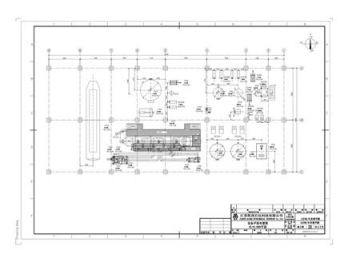

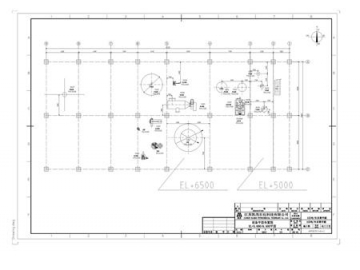

Projects Were Work on

Related products

Send Message

Most Recent

More

Other Products

Videos