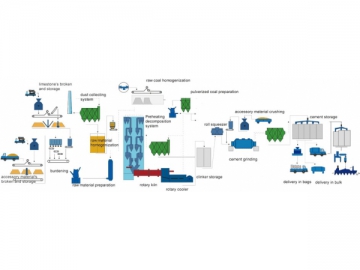

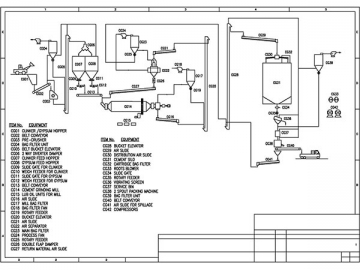

Grinding Line

1. belt scale on the feeder

2. blending station

3. belt conveyor for mixture

4. iron remover

5. elevator before roller press

6. conveyor for marginal materials

7. screw feeder

8. storage silo

9. constant feeder

10. roller press

11. storage silo

12. conveyor for returning oversize particles

13. cyclone

14. dust collector

15. exhaust blower

16. powder concentrator

17. elevator for discharge

18. conveyor for finished product

19. cement silo

20. elevator at the side of the cement silo

21. mill

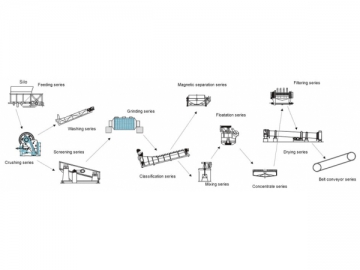

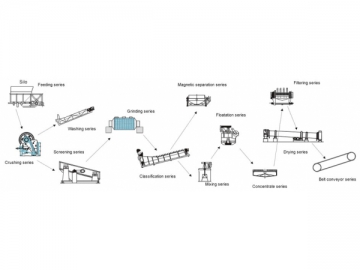

Grinding production line consists of jaw crusher, bucket elevator, electro-vibrating feeder, mill, powder concentrator, auxiliary engine, blast blower and centralized control system.

First, raw materials are dumped into the jaw crusher for size reduction. Then they are transported through the bucket elevator to the storage silo. Then the electro-vibrating feeder continuously and evenly brings the materials to the mill for further grinding. Driven by the blast blower, the powder obtained will enter the powder concentrator for separation. Later, separated fine particles will be delivered to another storage soli and finally leave from discharge valve as finished product.

The whole production line works in negative pressure. Along with the fine particles, the air blown out from the blast blower enters the cyclone collector at the top of the storage soli, and then returns to the blast blower though return air duct. In this way, the air can be recycled. Furthermore, the dust collector is fitted with a powder lock at the bottom, which isolates the positive pressure of the environment from the negative pressure of the dust collector. As a result, the yield is boosted significantly. In addition, the remaining air and powder at the bottom of the main machine will be delivered to the bag-type dust collector for filtration. Both dust and impurities can be absorbed by the bag-type dust collector, thus protecting the environment efficiently.

The production line is suitable for processing a wide variety of materials including pebble, granite, diabase, limestone, calcite, dolomite, barite, talcum, gypsum, bentonite and cement clinker. It is primarily applied for production of power used in many areas which include mining industry, electric industry, chemical industry, production of construction materials, metallurgical industry, production of refractory matter, desulphurization in power plants, asphalt mixing stations and construction of expressways.

The finished product size of our grinding line is ranging from 20 to 3250 mesh. Please refer to the technical parameters for the value of capacity. Our grinding line has been successfully utilized for non-metallic ore processing in a southern plant and desulphurization of limestone in a thermal power plant in Shijiazhuang.