Cement Plant Equipment

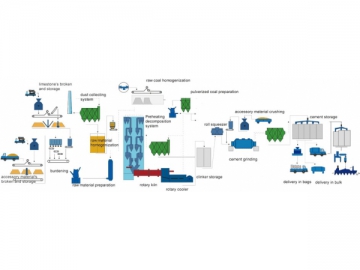

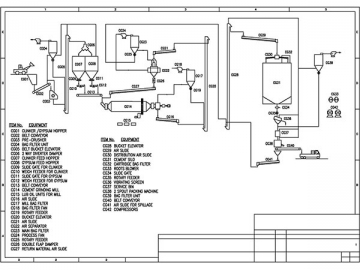

Cement production line usually consists of raw material mill, rotary cement kiln, cyclone pre-heater, cooler and clinker mill. The production process includes prehomogenization, which combines crushing and homogenization, homogenization of raw materials, preheating and decomposition, burning, finish grinding and packing.

Generally, at least three tons of materials including various raw materials, fuels, clinkers, mixtures and gypsums are required for production of one ton of portland cement. According to the statistics, grinding process will cost more than 60 percent of the total energy consumption in a dry process cement production line. Specifically, raw material grinding requires over 30 percent energy; coal grinding consumes about 3 percent, while cement grinding needs 40 percent or so. Therefore, high product quality and low energy consumption can be achieved through proper selection of grinding machines, optimization of technical parameters, standardization of operation and reasonable control of production progress.

Nowadays, dry process is primarily applied for production of cement. In a dry process, raw materials are dried and grinded at the same time. Then the raw material powder obtained is delivered to a dry process kiln for production of clinkers. The semidry process is a variation of the dry process. In a semidry process, certain amount of water is added into the raw material to make pellets, which are then fed to a rotary kiln for production of clinker through burning process.