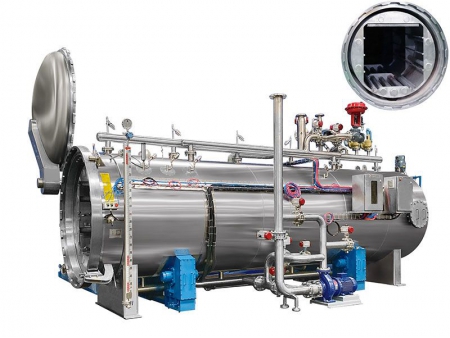

Water Spray Rotary Retort

Request a Quote

Water Spray Rotary Retort

Water spray rotary retort utilizes the rotating motion to accelerate the heat transfer rates of the products inside the package. A heat exchanger is used for heating and cooling, thus preventing products from being contaminated by steam and cooling water. The process water is drawn by a water pump, and continuously sprayed onto every inch of products by the spray nozzles distributed throughout the retort for the sterilization goal. Accurate temperature and pressure control make this retort perfect for sterilizing food and beverages packaged in various containers.

Application

- Package type: rigid containers (tin cans, aluminum cans/bottles), plastic bottles/cups/, glass jars/bottles, flexible pouches

- Food type: beverages (protein powder, tea, coffee), milk, fruits and vegetables (mushroom, beans), baby food, ready meals and soups, pet foods

Features

- Precise pressure control, suitable for different package types

- The pressure control module developed by DTS continuously changes the pressure during the entire process to adapt to the pressure variations inside the package. This minimizes the deformation of the package, no matter it is rigid container of aluminum/tin cans, or plastic bottles/boxes, or flexible pouches. The pressure accuracy is within ±0.05bar.

- Highly clean product package

- Heat exchanger is applied for indirect heating and cooling, thus avoiding secondary contamination caused by the steam and cooling water since they do not come into contact with the process water. Besides, water treatment chemicals such as chlorine are no longer required, and the service life of the heat exchanger can also be considerably extended.

- Energy saving and eco friendly

- A small amount of process water is used for circulation, enabling the sterilizing temperature to be reached quickly.

Low noise offers a silent and comfortable working environment.

In contrast to direct steam sterilization, there is no need for removing air from the retort prior to heating, resulting in significant steam savings of 30%.

- Rotary system has simple structure and stable performance

- The rotating body structure is molded through one-pass process, and then undergoes balanced treatment to ensure the concentricity and stability during rotating.

The supporting roller system comes with simple structure, delivering easy maintenance and prolonged service life.

The clamping system adopts double-way cylinders, and the guide structure is stressed to prolong the service life of the cylinder.

- In compliance with FDA/USDA certificate

- Backed by its team of seasoned thermal processing specialists, DTS has become a member of IFTPS and works in full cooperation with FDA-recognized third-party accreditation bodies. Years of experience in working with many North American customers means we understand the regulatory requirements of FDA/USDA and state-of-the-art sterilization technology.

Diameter Options

(the above sizes can support 3 to 6 baskets)

Leave Your Message

Related products

Send Message

Most Recent

More

Other Products

Videos