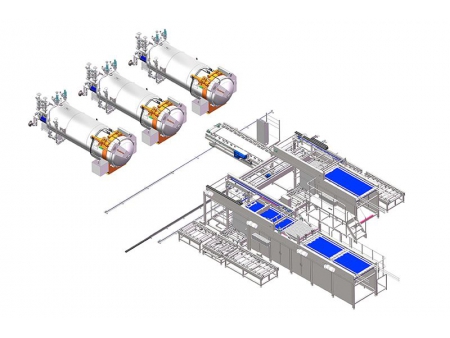

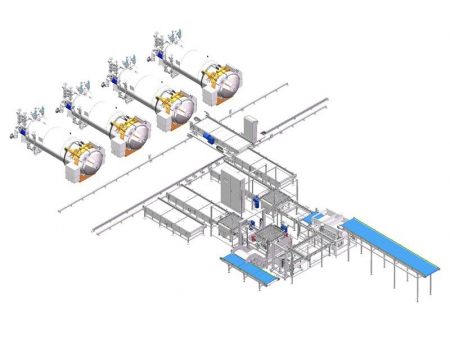

Rotary Retort

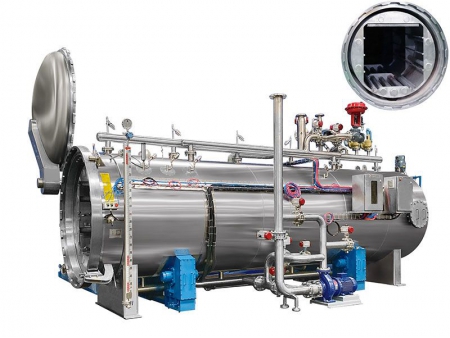

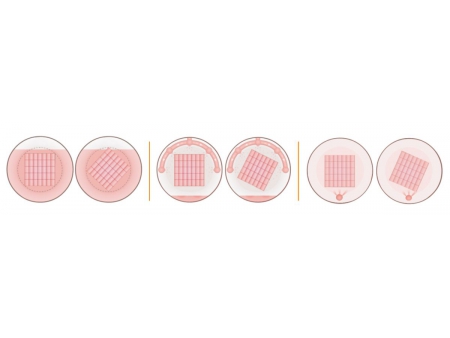

Rotary retorts are built to sterilize canned instant soup, porridge and other semisolid foods with high viscosity by rotating cans and containers during the process. This food sterilizer rotates 360 degree slowly and continuously to turn the canned foods inside the retort chamber, therefore creating uniform heating and cooling of food contents. This batch retort agitates the cans and containers in a thorough manner by rotating to increase convective heat transfer, so that the processing time can be significantly reduced. Besides, precise control of temperature and pressure is delivered to ensure the seal integrity of sterilized cans and containers without causing deformation or heat damage.

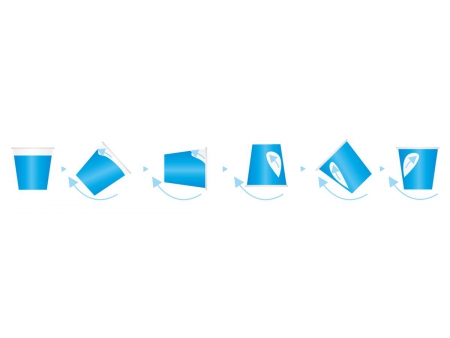

The rotary retort is suitable for sterilizing tinplate cans and plastic cups of breakfast porridge, condensed milk and more semisolid foods.

Our rotary retorts are available in different options of sterilization process such as water spray sterilization, water immersion sterilization and steam sterilization to accommodate specific food formulations, providing efficient heat penetration and retaining the nutritional content of foods.

-

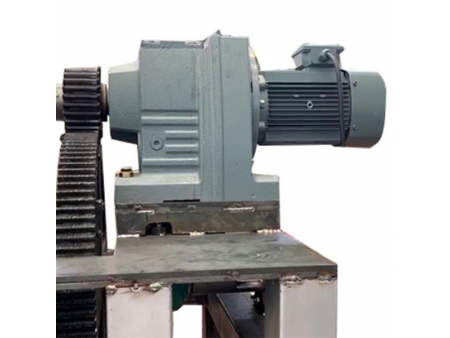

- The motor ensures that the retort can be accurately stopped in a horizontal position.

-

- The supporting roller at the front is removable for easy maintenance. The enhanced structure of the roller is featured by long service life and good wear resistance.

-

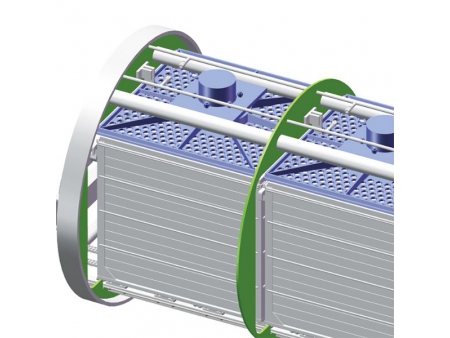

- Rotating cage is made of perforated stainless steel with integral welded structure, featuring high strength and good deformation resistance. The rotating cage is designed with 3-point support which is less prone to failure in comparison to 5-point support cage, thus minimizing the machine downtime and improving production efficiency.

-

- Cylinder automatically moves the clamping plate to clamp the retort basket, ensuring reliable performance with easy operation.

| Model | Dimension (mm) | Retort wall thickness (mm) | Max. working pressure (MPa) | Max. working temperature (°C) | Approx. retort weight (kg) | Approx. operating weight (kg) | Capacity (m3) | Power (kW) | Voltage (V) | ||

| L | W | H | |||||||||

CTXZ14-4 | 5450 | 3750 | 2400 | 6 | 0.3 | 130 | 3800 | 18000 | 6.77 | 29.5 | 380 |