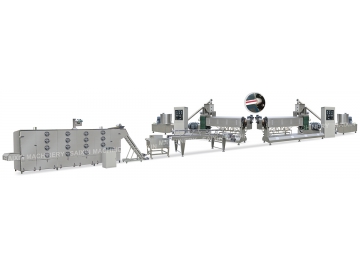

Udon Noodle Machines

As an experienced commercial noodle machine manufacturer, we suggest our udon noodle machines if you wish to make Japanese noodles at your noodle plant or pasta factory. Our udon noodle machines can efficiently make Japanese noodles of the same quality as hand-craft noodles without requiring high labor intensity, this because our noodle machines effectively combine the traditional noodle making method with advanced technology. We can also provide complete udon noodle production line that carries out each step necessary to make noodles from scratch. Dongfang Noodle can provide individual solution of Japanese noodle making machine for your noodle shop.

Udon noodles are made with wheat flour, water, and salt, which is a type of wheat flour noodle commonly used in Japanese cuisines. These fat noodles become so popular for their springy, supple texture and neutral flavor. Udon noodles can be served in hot dashi soup , or eaten cold by dipping in a soy-sauce based sauce, or stir-fried with meat and vegetables. Our company provides two kinds of udon noodle production lines for manufacturing instant udon noodles and vacuum packed udon noodles. The noodle production equipment can be configured based on customer needs.

-

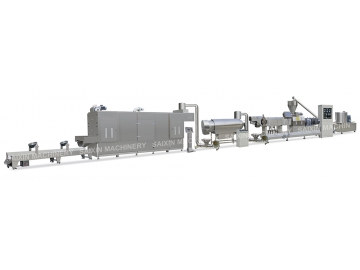

Noodle-Sheet Press Roller with 4-Axis Feed

The new type roller machine adopts four-axis feeding, which ensures the completeness of the dough sheet, and the edges and pieces are not broken. The effective combination of photoelectric tracking and conveyor belt realizes automatic dough sheet feeding and reduces labor intensity. The variable diameter pressing roller and carefully designed rolling ratio ensure that the extruded dough sheet has a uniform thickness, brightness and toughness, and a new appearance. New design and safety protection make it has taken on an entirely new look.

-

Water-Sealed Multi-Layer Steamer

The water-sealed multi-layer steamer adopts the low-in and low-out process, which effectively reduces the steam consumption. The well-designed steam nozzle makes the noodles fully gelatinized. The integral cover is water-sealed and replaced with rubber strips to ensure no steam leakage. The steamer cover is lifted and opened as a whole, which improves the efficiency of equipment cleaning and maintenance.

-

Automatic Noodle Boiling Machine

Cook the noodles in the noodle boiling machine, so that the water can fully enter the noodles and improve the taste and gluten of the noodles.

-

Drying and Sterilizing Machine

The bagged noodles are sterilized at high temperature to extend the shelf life