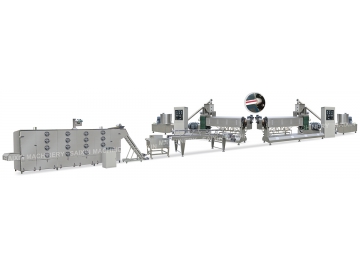

Stick Noodle Machines

Stick noodles, sometimes called dragon whisker noodles or dragon beard noodles, are a variety of noodles as thin as dragon's beard hair. It is highly challenging for chefs to make noodles as thin as dragon's whiskers, even Michelin chefs have given up on this dish. With Dongfang Noodle stick noodle machines, dragon whisker noodles can be easily made without the need for extensive training. Noodle making machines enable anyone to produce stick noodles at an artisanal level, with high consistency.

-

Horizontal Continuous Mixer

The highly automatic continuous dough mixer can save labor and construction cost by combining screw feeding, water supplying, mixing and dough feeding together. The dough absorbs water fully and evenly.

-

Dough Ripening Conveyor, 1500 Type

The ripening conveyor ripens flour in a static state for a certain period of time, so that the dough fully absorbs water and the gluten quality of the dough improves.

-

Compounding Press Roller

Rolling machine adopts different diameter rollers, is advantageous to the gluten forming; Ripple roller rolling makes the dough sheet draging in multi directions, which improves the dough sheet quality. Each roller adopts an independent motor, effectively ensuring the reliability of the transmission, and the structure is simplified, easy to maintenance.

-

Noodle Cutting Machine

The noodle cutter features high level of automation. With the technology of speed adjusting system, noodle length can be controlled as desired.

-

Device for Rod Feeding and Noodle Roller Cutter Storage

The noodle roller cutter storage device is convenient and quick to change the cutter within 2 minutes. The replacement can be completed in two minutes. Cutting and rod feeding machine adopts single transmisstion structure, which is controlled by PLC. The length of noodle is adjustable.

-

Swing Conveyor

Loading onto the drying rack by swing conveying is our company's latest technology. This new loading method simplifies the structure, overcomes the phenomenon of dislocation and falling of rods caused by chain stretching in traditional up-shelve, and has accurate alignment and zero rods falling.

-

Noodle Drying Room

The Dongfang newly designed tunnel with adoption of special chain system and longitudinal conveying system, keeps moisture and temperature changing continuously with stable noodle conveying. The humidity and tempreture of each drying section is adjusted by frequency control, which is convenient and reliable. The reasonable drying room design makes the both end humidified air flow toward the middle, reducing the energy consumption of 20-30%.

-

Air-Dried Noodle Transfer Device

There are various ways for customers to choose from: direct unloading of air-dried noodle and unloading with mechanical arm to ensure reliable connection with the noodle cutting and packaging device.

-

Dough Scrap Recycling System

After the noodle scrap fell, it is automatically pulverized, conveyed by air, automatically added to the flour in proportion, and entered into the dough mixing system, and no labor is needed during the period, which is safe, hygienic and automatic.

All versions include a device that captures the scraps and reintroduces them into the mixing tank.