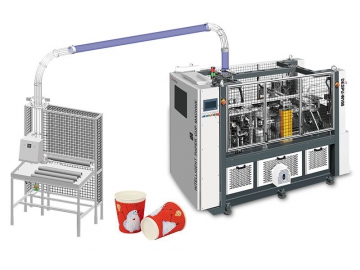

Paper Cup Outer Sleeve Forming Machine, DESPU-W140

Suitable for making paper coffee sleeves and insulated ripple sleeves

DESPU-W100 is ideal for producing milk tea cups, instant noodle cups, coffee cups, corrugated cups and other jacket forming machines. Used together with the C series paper cup machine, it can produce air-insulated double-walled coffee cups, as well as insulated cups with embossed jacket tubes. This machine allows the production 150pcs of of 8-22oz cups every minute.

- Output in every shift (8 hours) achieves 38,000 cups, and monthly output ( in 3 shifts) arrives 3.00 million cups.

- Qualified rate is higher than 99% in normal production.

- Machines can be processed simultaneously by single operator.

- 5-year warranty for driving part, and 1-year warranty for electronical parts and wearing parts.

- Easy inspection and maintenance for parts on forming table.

- All parts under forming table should be lubricated every four to six month with specified oil.

Cylinder cam drive, gear driving, vertical shaft are well equipped for multiple functions. Spray lubrication is adopted for whole machine. PLC control, photoelectric tracking and servo feed system are applied for the electronical parts.

-

Vertical axis adopts gear drive, cylindrical cam optimizes internal layout, all of these can ensure the transmission accuracy of this paper cup making machine, improve the synchronization performance, so as to achieve the coordination of the stroke, and avoid component damaged.

-

This high speed paper cup machine is designed with box type structure, oil spray and oil lubrication can reduce wear and tear, and heat effectively, so that the machine achieves rapid operation.

-

The paper cup making process is controlled by PLC, optical eye monitoring system is adopted, servo control system is used to control feeding the cup bottom, if there is no cup wall, the system will not convoy the cup bottom.

-

All electrical components are from OMRON and Schneider. The control system adopts PLC programmable controller and touch screen human-machine interface.

-

Gluing machine is working with paper cup machine, the paper cups will be conveyed to the gluing machine through pipeline for forming.

| Model | DESPU-W140 |

| Output | Middle hollow, flat pasting:120-150 pcs/min Double-wall corrugated paper:80-100 pcs/min Single-wall corrugated paper:60-80pcs/min |

| Dimension(oz) | 8-22oz |

| Application | Milk tea cups, instant noodle cups, coffee cups, corrugated cups and other jacket molding |

| Cup Shape | |

| Paper Type | Grey Bottom White Board/ White Card |

| Paper Thickness | 0.2825-0.4075mm Single-wall corrugated paper:0.245-0.2825mm |

| Cup Size | (D1)ф70-95mm (H)60-135mm (D2)ф50-75mm (h)5-12mm |

| Power | 3-phase 380V、5KW |

| Compressed Air | 0.6-0.8MPa、0.4m³/min |

| Paper Feeding | ○ |

| Control Panel | 7 inches |

| Weight | 2300kg |

| Packaging Box Size | 2900 x 1400 x 2100mm |

Note: Optional Configuration ○ Standard Configuration ●