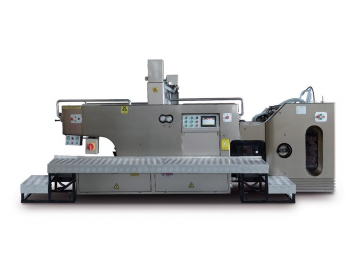

Infrared and Ultraviolet Dryer

Request a Quote

Application

The infrared and ultraviolet dryer is divided into multiple chambers, which are freely connected in order to meet different printing requirements. This allows the infrared and ultraviolet dryers to be widely used for the solidification of a variety of UV inks and pigments.

The standard configuration comes with 3 groups of hot dryers, a set of UV curing devices and a set of AC cooling devices, ensuring a satisfactory solidification effect.

Specification| Model | JB-800P | JB-1100P | |

| Max. conveying speed | 60m/min | 60m/min | |

| Conveying motor power | 0.75KW | 0.75KW | |

| Effective curing width | 800 mm | 1100mm | |

| IR group | Max. temperature | 120℃ | 120℃ |

| Frist group | 1.5kw×12pcs | 1.5kw×12pcs | |

| Other groups | 1.5kw×9pcs×(team-1) | 1.5kw×9pcs×(team-1) | |

| Hot wind circulation fan | 1.1kw×2×3team | 1.1kw×2×3team | |

| UV group | UV lamp power | 10.0kw×3pcs | 10.0kw×3pcs |

| UV Exhaust fan power | 0.37kw×3 | 0.37kw×3 | |

| Weight | 450kg×teams+300kg | 500kg×teams+300kg | |

| Overall dimensions | (2×teams+1500)×1870×1850mm³ | (2×teams+1500)×2090×1850mm³ | |

- Closed cycle pipelines are evenly distributed inside the dryer, and are responsible for maintaining an efficient and stable hot air flow. The hot air is ejected downwards onto the objects on the conveyor belt as a beam aperture. The heat transfer coefficient is large, and the drying process is fast with a low energy consumption.

- The cool wind in the cooling system forms a constant downward cold air flow with the help of a high pressure blower, and is able to quickly lower the object temperatures.

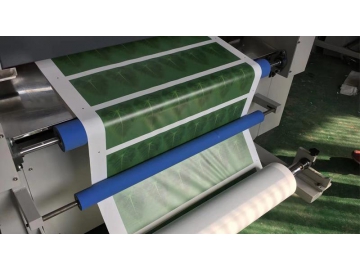

- The variable frequency conveying system uses a conveyer belt made of heat resistant, friction resistant and radiation resistant Teflon, guaranteeing a long service life.

- There is a pneumatic lifting set in the dryer, which make it easy to clean and maintain.

- The automatic tensioning and correcting mechanism ensures a stable conveying and operation convenience.

Related products

Send Message

Most Recent

More

Other Products

Videos