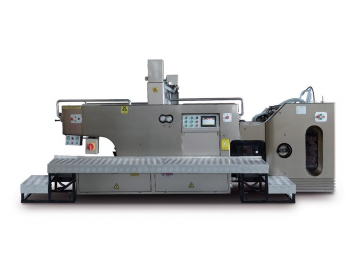

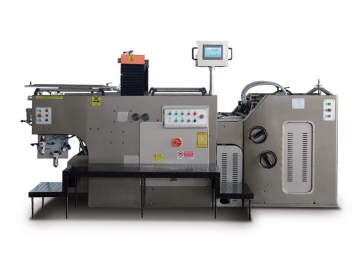

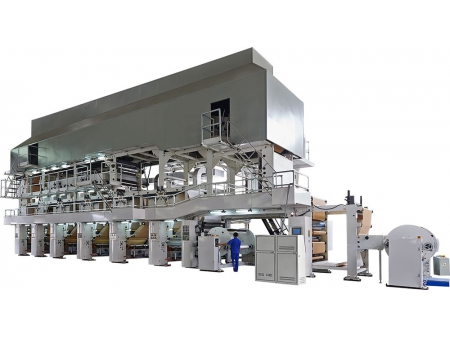

JB-1050A Full Automatic Stop Cylinder Screen Printing Machine

Recommended application

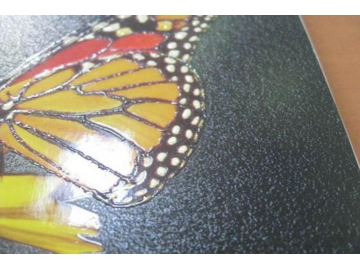

The JB-1050A full automatic stop cylinder screen printing machine employs classic stop cylinder technology and is designed with a high running speed of 4000 sheets/h. The applicable printing substrates include ceramic and glass decorative paper, textile, paper, signboard etc., thus it can be widely applied to screen printing for advertising, packing, garment, electronics and many other industries.

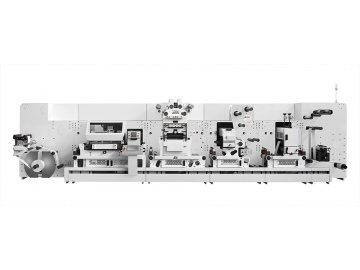

If linked with a UV curing machine, rotary vane type screen printing dryer or infrared and ultraviolet dryer, as well as automatic paper stacker, a fully automatic screen printing line can be constituted to further improve the work efficiency.

Technical parameters| Max. paper size | 1050×750mm2 |

| Min. paper size | 560×350mm2 |

| Max. printing size | 1050×750mm2 |

| Size of screen frame | 1300×1170mm2 |

| Max. pile height | 700mm |

| Paper weight | 90-420g/m2 |

| Border | Less than 10mm |

| Printing speed | 800-4000pcs/h |

| Installed power | 10.7KW |

| Power supply | 3P, 380V, 50HZ |

| Total weight | 5600kg |

| Overall size | 4080×3020×1750mm3 |

Features of JB-1050A full automatic stop cylinder screen printing machine

Classic stop cylinder mechanism

The automatic stop cylinder ensures that the printing substrates can be conveyed to the gripper with extreme high accuracy and stability.

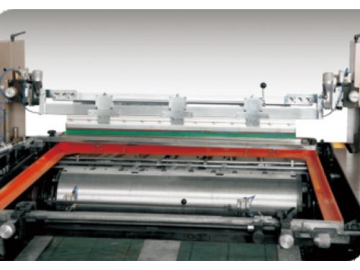

Transfer system

The transfer system with adjustable vacuum antiskid absorption acts on the papers' non-printing surface significantly reducing rubbed scratched papers and enabling accurate stable paper feeding.

Squeegee system

The squeegee pneumatic pressure kept device allows for constant printing pressure and uniform ink layer and clearer printing pattern.

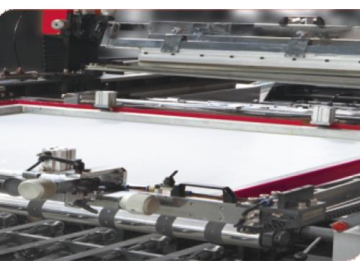

Screen structure

The screen frame taken out design both facilitates the register of substrates and the adjustment of feeding, and makes the cleaning of the cylinder and the screen safer and faster. Ink dropping pan is equipped to prevent ink dropping and wasting.

Centralized lubrication system

Automatic lubrication for main drive and main components effectively improves the use precision and extends the machine life.

Automatic alignment system

The self-setting type CNC sensor registration system is also equipped on the screen printing machine. When the printing substrate arrives at the position of the front and side lays, it is registered through the detecting sensor. If any slight misplacement appears, it will automatically stop printing to guarantee high accuracy of overprint and thus effectively reduce the reject ratio.

Electrical control

PLC centralized control of the operation of the whole machine. It is easy to operate with the touch screen and button dual operating system. Man-machine dialogue operating interface can display the equipment status and the cause of faults in real time.

Others

Delivery board

Delivery board Optional safety light curtain

Optional safety light curtain