E Series Diesel Engine for Construction Machinery

The SDEC E series engine features a high reliability, good response and strong power, as well as the advantages of a large torque at low speed and low fuel consumption when compared to similar products of the same power. This product has a large torque reserve and a power ranging from 213 kW to 353kW, meeting Off-Road China III and above emission standards, making it a popular choice for a new generation of high end construction machinery.

The E series engine was designed jointly with the Austrian company AVL by referring to current advanced engine design concepts from around the world. Satisfying the demands for high reliability, high efficiency and low oil consumption for heavy-duty commercial vehicles, construction machinery and high-duty agriculture machinery, this engine series is a brand new four-valve engine platform created by following SAIC MOTOR manufacturing standards.

| Diesel Engine | Engine Model | Displacement (L) | Aspiration | Rated Power | Peak Torque | Solution | Emissions Level | ||

| kW | r/min | N.m | r/min | ||||||

| 10E | SC10E300 | 10.4 | TA | 220 | 2100 | 1350 | 1400 | CRS | China III |

| 10E | SC10E320 | 10.4 | TA | 235 | 2100 | 1450 | 1400 | CRS | China III |

| 10E | SC10E350 | 10.4 | TA | 258 | 2100 | 1600 | 1400 | CRS | China III |

| 12E | SC12E340 | 11.8 | TA | 250 | 1900 | 1550 | 1300 | CRS | China III |

| 12E | SC12E360 | 11.8 | TA | 265 | 1900 | 1650 | 1300 | CRS | China III |

| 12E | SC12E385 | 11.8 | TA | 283 | 1900 | 1700 | 1300 | CRS | China III |

| 12E | SC12E395 | 11.8 | TA | 290 | 1900 | 1950 | 1300 | CRS | China III |

| 12E | SC12E430 | 11.8 | TA | 316 | 1900 | 2100 | 1300 | CRS | China III |

| Natural Gas Engine | Engine Model | Displacement (L) | Aspiration | Rated Power | Peak Torque | Emissions Level | ||

| kW | r/min | N*m | r/min | |||||

| 12ET | SC12ET310 | 11.8 | TA | 228 | 1900 | 1250 | 1400 | China III |

| 12ET | SC12ET350 | 11.8 | TA | 258 | 1900 | 1540 | 1400 | China III |

| Bore x stroke(mm) | Aspiration | Type | Compression ratio | Solution |

| 10ET 128x135 12ET 128x153 | TA Turbocharged and intercooled | 10E/12E/10ET/12ET In-line, six cylinders | 10E/12E 17: 1 10ET/12ET 11: 1 | CRS electronically controlled common rail EGR external EGR Electronically controlled premixing |

| E series | Technical features | Customer value |

| Fuel system | Using a Bosch electronically controlled shared-rail system, the injection pressure is 1800bar, with multiple injection, uniform atomization and reasonable distribution, making the combustion more full. | The fuel consumption is over 10% lower than similar products. This engine meets Off-Road China III and above emission standards |

| Gas system | Using WOODWARD proven and reliable OH2.0 electronically controlled fuel system and lean burning technology, the air-fuel ratio is accurately controlled with a low fuel consumption, which meets China V emission standards. | This system is advanced. reliable and economical |

| Aspiration method | With designs of four-valves per cylinder and a parallel airway, and high-efficiency exhaust turbocharger and intercooler chosen based on different working conditions, a higher air intake efficiency is achieved for full burning. The maximum torque reserve is as high as 38% and the transient load response at a low speed is fast. | With a low oil consumption, the power is strong. |

| Design features | Using the Benz DD13 as prototype, SDEC cooperated with the Austrian company AVL to design this engine with a peak pressure as high as 190bar. It uses an overhead camshaft, Bedplate high strength cylinder block, rear gear chamber and noise and vibration reduction designs. With a self-regulating variable displacement oil pump, integral engine oil cooling and filtering module and dual engine oil filtering, the engine oil has a long life span. | The design is reliable. With low vibration, the noise is reduced by 3dB, ensuring excellent user comfort and low usage costs. |

| Reliability features | Using automatic production lines created by MAG and other international first-class brands, it is controlled by an MES system. Referring to SPS system guarantee from German Volkswagen manufacturing standards, the product has a high consistency. Developed by the GPDP product research and development process, testing of platform reliability and durability is conducted for over 20000 hours, and more than 1.5 million km of special tests and verification of different types and working conditions during the research and development stage. | This engine has an excellent quality and no downtime. |

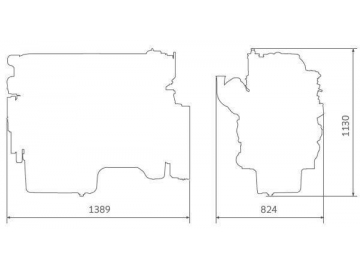

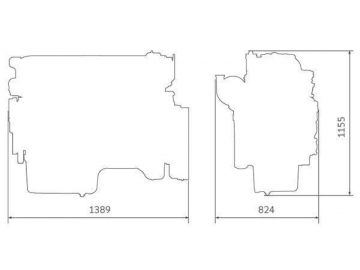

| Matching adaptability | With an optional displacements of 10.4L and 11.8L, and optional engines fueled using diesel or natural gas, the power ranges from 213kW to 353kW. Without am auxiliary air intake heating device, the cold starting temperature is -15℃. The engine and assembly are conducted using matching optimization and customization based on the assembly configuration and actual operating conditions. Various configurations for flywheel, flywheel house, engine, air compressor and other peripheral parts are available, as well as different structures and types for PT0 and oil pans to choose from. | Various fuel types are available, as is a wide power range. Excellent environmental adaptability. It meets user needs for variety and customization. |

| Maintenance | The engine oil draining interval is up to 80000km without a valve clearance adjustment within 80000~ 100000 km. With a cracking connecting rod design, maintenance is easy, with less quick-wearing parts. | The maintenance cost is reduced, with little to no down time and easy maintenance. |

Related Products

diesel engine for construction machinery, SDEC engine, construction equipment power