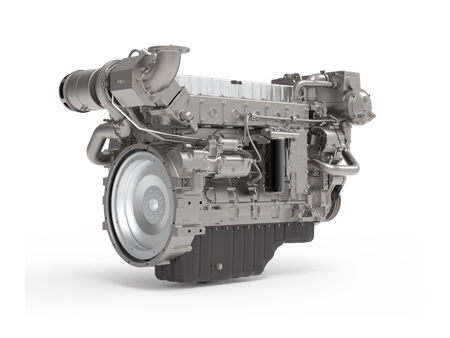

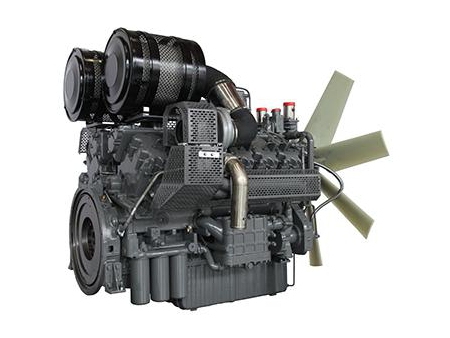

D Series Diesel Engine for Construction Machinery

The SDEC D series engine features a high reliability and low fuel consumption, and is a recently designed engine that features advanced technology, making it one of the most popular engine series on the domestic market. Its maximum torque reserve is as high as 40% and the power ranges between 105KW to 275KW, meeting China III off-road emission standards.

The prototype engine of the D series was designed together with the Austrian company AVL, based on Chinese oil quality and user application habits. In 2005, SDEC worked with the American Southwest Research Institute (SwRI) to improve the reinforced design and four valve upgrade. It is designed based on American heavy duty diesel engine standards, and is an environmentally friendly power source, meeting higher emission standards. This engine series has sold for more than 20 years, with upwards of 1 million sets currently in circulation.

| Diesel Engine | Engine Model | Displacement (L) | Aspiration | Rated Power | Peak Torque | Solution | Emissions Level | ||

| kW | r/min | N.m | r/min | ||||||

| 8D | SC8D143 | 8.3 | TA | 105 | 1900 | 750 | 1300 | CRS\EGR | China III |

| 8D | SC8D160 | 8.3 | TA | 118 | 2000 | 680 | 1400 | CRS\EGR | China III |

| 8D | SC8D160.1 | 8.3 | TA | 118 | 1800 | 750 | 1400 | CRS\EGR | China III |

| 8D | SC8D170 | 8.3 | TA | 125 | 2200 | 730 | 1400 | CRS\EGR | China III |

| 8D | SC8D170.1 | 8.3 | TA | 125 | 2000 | 750 | 1400 | CRS\EGR | China III |

| 8D | SC8D175 | 8.3 | TA | 128 | 2200 | 750 | 1400 | CRS\EGR | China III |

| 8D | SC8D175.1 | 8.3 | TA | 128 | 2000 | 750 | 1400 | CRS\EGR | China III |

| 8D | SC8D175.2 | 8.3 | TA | 128 | 1800 | 820 | 1300 | CRS\EGR | China III |

| 8D | SC8D185 | 8.3 | TA | 136 | 2200 | 760 | 1400 | CRS\EGR | China III |

| 8D | SC8D185.1 | 8.3 | TA | 136 | 2000 | 840 | 1400 | CRS\EGR | China III |

| 8D | SC8D185.2 | 8.3 | TA | 136 | 1800 | 870 | 1300 | CRS\EGR | China III |

| 8D | SC8D190 | 8.3 | TA | 140 | 2200 | 820 | 1400 | CRS\EGR | China III |

| 8D | SC8D190.1 | 8.3 | TA | 140 | 2000 | 880 | 1400 | CRS\EGR | China III |

| 8D | SC8D190.2 | 8.3 | TA | 140 | 1800 | 980 | 1400 | CRS\EGR | China III |

| 8D | SC8D200 | 8.3 | TA | 147 | 2200 | 860 | 1400 | CRS\EGR | China III |

| 8D | SC8D200.1 | 8.3 | TA | 147 | 2000 | 920 | 1400 | CRS\EGR | China III |

| 8D | SC8D220 | 8.3 | TA | 162 | 2200 | 920 | 1400 | CRS\EGR | China III |

| Diesel Engine | Engine Model | Displacement (L) | Aspiration | Rated Power | Peak Torque | Solution | Emissions Level | ||

| kW | r/min | N.m | r/min | ||||||

| 9D | SC9D160 | 8.8 | TA | 115 | 1800 | 800 | 1300 | CRS\EGR | China III |

| 9D | SC9D190 | 8.8 | TA | 140 | 1900 | 920 | 1400 | CRS\EGR | China III |

| 9D | SC9D200 | 8.8 | TA | 147 | 2200 | 860 | 1400 | CRS\EGR | China III |

| 9D | SC9D210 | 8.8 | TA | 155 | 2200 | 910 | 1400 | CRS\EGR | China III |

| 9D | SC9D220 | 8.8/9.3L | TA | 162 | 2200 | 950 | 1400 | CRS\EGR | China III |

| 9D | SC9D220.1 | 8.8 | TA | 162 | 2000 | 980 | 1400 | CRS\EGR | China III |

| 9D | SC9D230 | 8.8 | TA | 170 | 2200 | 1000 | 1400 | CRS\EGR | China III |

| 9D | SC9D240 | 8.8 | TA | 177 | 2200 | 1040 | 1400 | CRS\EGR | China III |

| 9D | SC9D240.2 | 8.8 | TA | 177 | 2000 | 1100 | 1400 | CRS\EGR | China III |

| 9D | SC9D250 | 8.8 | TA | 184 | 2200 | 1110 | 1400 | CRS\EGR | China III |

| 9D | SC9D250.1 | 8.8 | TA | 184 | 2050 | 1110 | 1400 | CRS\EGR | China III |

| 9D | SC9D260 | 8.8 | TA | 192 | 2200 | 1110 | 1400 | CRS\EGR | China III |

| 9D | SC9D270.1 | 8.8 | TA | 200 | 2200 | 1150 | 1400 | CRS | China III |

| 9D | SC9D270 | 8.8 | TA | 200 | 1800 | 1250 | 1300 | CRS | China III |

| 9D | SC9D280 | 8.8 | TA | 206 | 2200 | 1200 | 1400 | CRS | China III |

| 9D | *SC9DF280 | 8.8 | TA | 213 | 2200 | 1200 | 1400 | CRS | China III |

| 9D | *SC9DF300 | 8.8 | TA | 220 | 2200 | 1300 | 1400 | CRS | China III |

| 9D | *SC9DF320 | 8.8 | TA | 235 | 2200 | 1380 | 1400 | CRS | China III |

| 9D | *SC9DF340 | 8.8 | TA | 250 | 2200 | 1450 | 1400 | CRS | China III |

| Natural Gas Engine | Engine Model | Displacement (L) | Aspiration | Rated Power | Peak Torque | |

| kW | r/min | N*m | ||||

| 9DT | SC9DT200 | 8.8 | TA | 148 | 2100 | 700 |

| 9DT | SC9DT220 | 8.8 | TA | 162 | 2200 | 930 |

| 9DT | SC9DT230 | 8.8 | TA | 170 | 2000 | 930 |

| 9DT | SC9DT250 | 8.8 | TA | 184 | 2200 | 960 |

| 9DT | SC9DT280 | 8.8 | TA | 170 | 2000 | 930 |

| 9DT | SC9DT280 | 8.8 | TA | 206 | 2100 | 1112 |

| 9DT | SC9DT280.1 | 8.8 | TA | 206 | 2100 | 1200 |

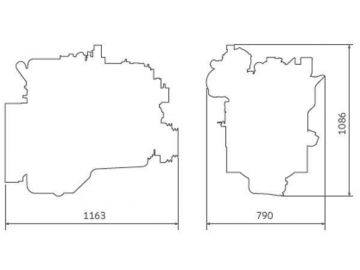

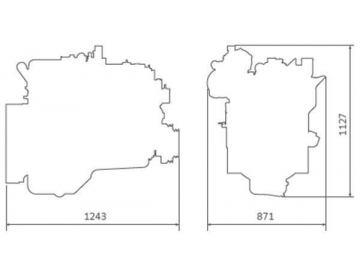

| Bore x stroke (mm) | Products with* are of 4-valve. | Aspiration | Type | Compression ratio | Solution |

| 8D 114x135 9D 114x144611652x144 90T 114x144 | TA Turbocharged and intercooled | 8D/9D/9DT In-line,six cylinders | 8D/9D 18: 1 9DT 11: 1 | CRS electronically controlled common rail EGR mechanical pump + external EGR Electronically controlled premixing |

| D series | Technical features | Customer value |

| Fuel system | 1. Electronically controlled shared-rail design: it uses the Japanese Denso third generation electronic control system, with a maximum injection pressure of 1800bar and DLC coated fuel injector of Denso patented technology. 2. Reducing the pitting corrosion and wear of fuel injector: this achieves multiple injections during sequential processes to ensure uniform atomization and full combustion. 3. Mechanical pump scheme: high quality mechanical pump + external EGR. | 1. The fuel consumption is reduced by 10-15%, thus extending the service life. 2. It meets Off-Road III and above emission standards. |

| Gas system | 1. The engine uses a single point injection gas supply mode and two control strategy: lean burning and mixed burning (lean burning + equivalent burning). 2. Controller (ECU), sensor, electronic throttle, sparking coil, spark plug and other key components are all sourced from internationally known brands. | This system is proven and reliable. |

| Aspiration method | With optional 2-valve and 4-valve products, optimized designs of combustion chamber and swirl ratio airway, the turbocharger is selected according to various working conditions, power and torque requirements. The higher air intake efficiency improves the combustion efficiency. It has a high power density, a maximum torque reserve of 40% and fast transient load response. | 1. With a low fuel consumption, the operation cost is low. 2. It has a fast transient load response, strong power and excellent adaptability to working conditions. |

| Design features | 1. By partnering with AVL and SwRI, this product meets North American heavy-duty diesel engine standards. With a high strength cylinder head and engine block, 4-valve structure and 180bar peak pressure, all the parts are designed at 295kW. 2. Using an integral design, the parts are 20% less than the general diesel engines, and feature a simple structure and a smaller size when compared with the same power engine. | 1. This engine has a high reliability and no downtime. 2. The overall layout is flexible. |

| Reliability features | 1. Designed as a 295kW heavy-duty diesel engine, it has a high reliability margin. With advanced machining and assembly lines, it is controlled by an MES system. 2. By referencing the SPS system guarantee of German Volkswagen manufacturing standards, the engine features an excellent consistency. 3. Using proven and reliable international first-class accessories, this engine has been a popular choice for more than 20 years, and is the preferred power for construction machinery. | It is an advanced, reliable and high performance engine. |

| Matching adaptability | 1. With optional displacements of 8.3L and 8.8L, optional 2-valve and 4-valve, and optional engine fuel sources of diesel or natural gas, the power ranges from 105kW to 275kW. 2. Without an auxiliary air intake heating device, the cold starting temperature is -15℃. 3. According to the assembly configurations and actual operating condition, the engine and assembly are conducted to match optimization and customization. 4. Various configurations for flywheel, flywheel house, engine, air compressor and steering pump are available. There are also various structures and types to choose from for the PT0 and oil pan. | 1. This engine has a wide application and excellent environmental adaptability. 2. It has the best power performance and economy. |

| Maintenance | 1. The electronically controlled engine can achieve intelligent real-time diagnosis. 2. With over 1 million sets in circulation, the maintenance network and spare parts suppliers are located all over China. | The maintenance cost is low. |

Related Products

diesel engine for construction machinery, SDEC engine, construction equipment power