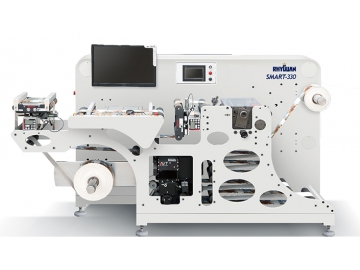

Inspection Rewinder, ZTM-E

Request a Quote

The ZTM-E inspection rewinder versatilely detects surface defects or printing mistakes, and rewinds rolls of various materials such as BOPP, PET, CPP, PVC, aluminum foil and paper.

Specifications

Details

| Model | |

| Web width | 1300mm |

| Unwinding diameter | Ø800mm |

| Paper core diameter | Ø76mm |

| Mechanical speed | 300m/min |

| Width of finished roll | 30-1300mm |

| Precision | 0.5mm |

| Weight | 2500kg |

| Total power | 15kW |

| Overall Dimensions (L×W×H) | 1735×2800×1800mm |

- Shaftless unwinder

- Rewind unit with air shaft

- PLC system

- EPC control

- Yaskawa servo motor

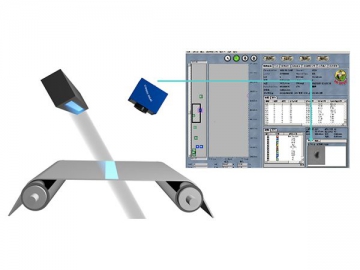

- Strobe light detection system

- Imported PLC and touch screen control panel ensures 100% inspection with easy operation.

- Unwind unit is driven by vector control frequency inverter, and the PLC control automatically calculates the roll diameter to keep the unwind tension control constant.

- Web traction control is managed by vector control frequency inverter, maintaining a constant speed.

- Inspection strobe light is adopted to assure the printing quality, allowing operator to manually stop the machine when any defect is found.

Related products

Send Message

Most Recent

More

Other Products

Videos