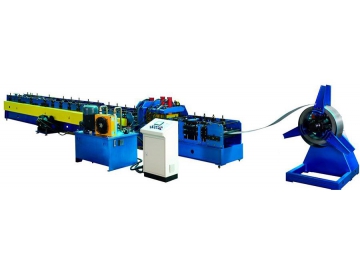

C80-300 Full Automatic Adjustable C Purlin Machine

C80-300 full automatic adjustable C purlin machine comes with automatic adjustment of product size without changing rollers or spacers within 1 min. Width adjustment is within 80mm-300mm and product thickness ranges from 1.2mm to 3.0mm. Optional punching system allows for punch hole at any position of the purlin.

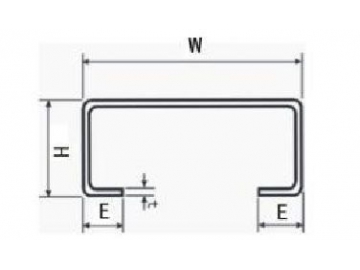

H: 35~100 mm

E: 10-20 mm

| Model | C80-300 |

| Dimension | 7800*1700*1600mm |

| Hydraulic Motor Power | 22kW |

| Motor Power for adjusting C size | 0.37kW*2 0.75kW |

| Motor Power for guiding | 0.18kW*2 |

| Motor Power for adjusting punching hole | 0.18kW*2 |

| Forming Steps | 13Steps 3Steps for reshaping |

| Forming Speed | 8m/min,16m/min,25m/min |

| Voltage | 380V/50HZ/3PH |

| Effective Width | 80-300mm |

| Material Width | 122-402mm |

| Flange Height | 35-100mm |

| Material Thickness | 1.2-3.0mm |

| Control System | PLC Computer Control |

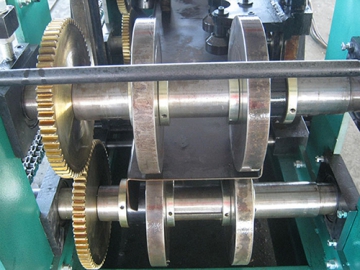

| Rollers | Gcr15 steel with heat treatment,plate hard chrome on the surface of rollers |

| Material for Shaft | 40Cr steel |

| Material for Puncher | Cr12Mov |

| Material for Cutter | Cr12Mov |

-

Punching system with 4 cylinders, available for single hole and double holes

-

Rollers are manufactured from high quality bearing steel GCr15 and are processed with CNC lathes and heat treatment. Hard-chrome coating and black oxide coating are for options. With a feeding material guide roller, body frame is welded with 400# H type steel.

-

Punching system is specially designed for C purlin to achieve automatic punching and improve the processing efficiency.

-

With pre-cutting system and post cutting system, there is no need to change cutter for different sizes.

-

Available operation for electric run out table

- Main Purlin Forming Machine

- 3 Tons Manual Uncoiler

- Automatic Guide Device

- Automatic Reshaping Device

- PLC Computer Controlling System With Touch Screen ( Brand: Schneider )

- Hydraulic Motor System

- Pre-punching Holes Device( the buyer decide the size of punching holes )

- Pre-cutting Device (Available to add post-cutter)

- Run Out Table

- Operation Manual