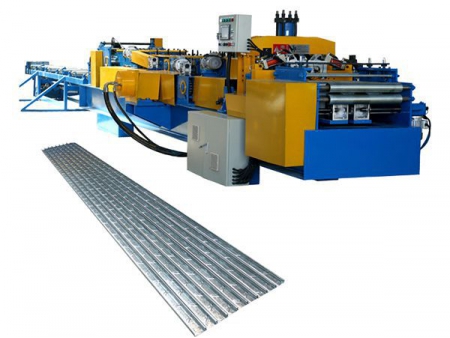

Z Purlin Forming Machine

Request a Quote

Equipment Configuration

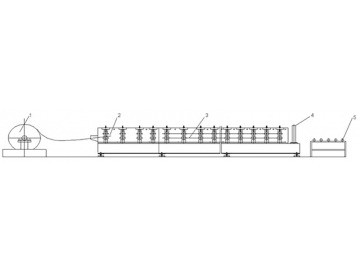

Feeding device, transmission, main machine and forming roller (including guide table), cutting (after roll forming) device, hydraulic system, electric control system, run out table, etc. Main rack of the machine is processed on the planer type milling machine.

- Rolling material: 2-3mm thickness, including 5 sets of common moulds

- Working speed: 8-10 M/min

- Step of rollers: 13 steps

- Main motor power: 15KW

- Hydraulic station motor power: 7.5KW

- Material of roller: CR12

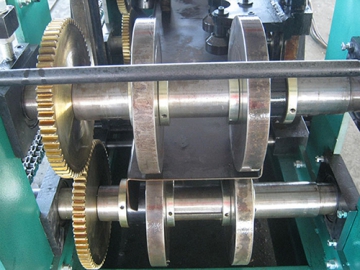

- Material of main shaft: 45# forged steel, quenching and tempering

- Spindle diameter: ¢90mm

- Wallboard thickness: 25mm

- Chain: double-row 20A

- Hydraulic station pressure: 10-12MPa

- Material of cutting blade: Cr12, quenched

- Seven rollers as flattening, two rollers as pinching

- Electric control system: Whole machine adopts PLC (Panasonic) frequency control, cut-to-length error≤±3mm

- Material Feeding Device

- Feeding

- Hydraulic Forming

- Hydraulic Cutting

- Discharging Device

Production process

Manually de-coiling →Guiding & feeding & correcting→ Roll forming → Cutting after roll forming → Finished product

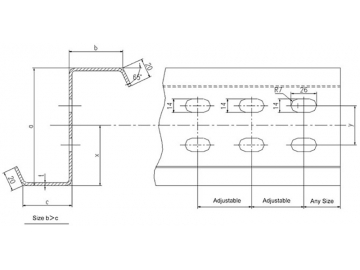

| Number | o | b | c | t |

| 1 | 150 | 62 | 57 | 2-3 |

| 2 | 160 | 62 | 57 | 2-3 |

| 3 | 180 | 77 | 72 | 2-3 |

| 4 | 200 | 77 | 72 | 2-3 |

| 5 | 240 | 77 | 72 | 2-3 |

| 6 | 250 | 77 | 72 | 2-3 |

| 7 | 300 | 92 | 87 | 2-3 |

- h=100mm, b=50mm, c=15mm, coil width=210mm

- h=150mm, b=50/60mm, c=20mm, coil width=270/290mm

- h=200mm, b=65/70mm, c=20mm, coil width=350/360mm

- h=250mm, b=70/80mm, c=20mm, coil width=410/430mm

- h=300mm, b=70/80mm, c=20mm, coil width=460/480mm

- The rollers of the Z purlin forming machine are made of forged quality structural steel after intense treatment. Coated with the hard chromium on the surface, the roller performs with expanded operation life.

- Under the control of computer, the machine accomplishes the length setting, punching and counting smoothly.

- The flattening rollers at the front end of the Z purlin forming machine are adopted to make the strip steel flat and smooth enough to meet the standards, making an increase of economic benefit.

- The Z purlin fabricated by our machine performs excellently on resisting bending. It is also easy for installation.

- The Z shaped purlin is commonly used in the middle and large scaled buildings like the factory, warehouse, garage, gymnasium, exhibition center, cinema, theatre, garden and so on. It is perceived as the applicable building materials to support the roof or forming the wall.

Related products

Send Message

Most Recent

More

Other Products

Videos