Soft Biscuit Production Line

Request a Quote

TG Machine offers a variety of equipment for soft biscuit production lines, designed to meet GMP food hygiene standards and customer requirements regarding different soft biscuit types.

The following are just a few common configurations and we will customize the soft biscuit production line to meet specific customer needs.

- Horizontal dough mixer

- Material feeder

- Dough conveyor

- Rotary molder

- Spreader

- Furnace charging conveyor

- Wire mesh belt conveyor

- Tunnel oven

- Furnace discharge conveyor

- Oil spray machine

- Vibrating spreader

- Turning conveyor

- Cooling conveyor

- Star wheel stacker

- Picking conveyor

Features

- The production line runs continuously, allowing customers to quickly recoup investment costs and ensure a large production output.

- It is a fully automatic production line requiring minimal human interference.

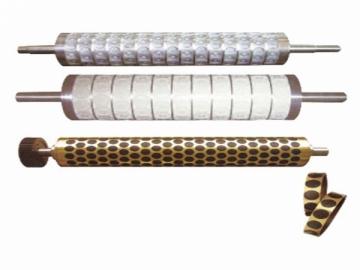

- Different biscuit shapes are achieved through the use of different, easy to change molds.

- We can customize molds according to your requirements.

- Production line components are manufactured here in house, ensuring the high quality and a quick supply of spare parts.

Standard

- Dough mixer

The dough mixer is necessary for manufacturing different biscuits and breads as it ensures dough is softer and stretchier. We will customize the dough mixer to meet specific customer requirements.

The dough mixer is necessary for manufacturing different biscuits and breads as it ensures dough is softer and stretchier. We will customize the dough mixer to meet specific customer requirements. - Material feeder

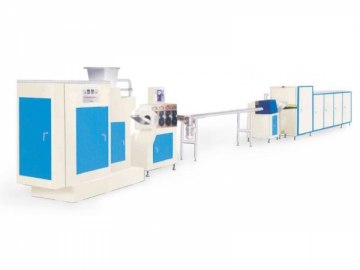

The material feeder is equipped with an automatic tensioning device and automatic deviation rectifying device to ensure reliable conveyance. The roller and groove roller are made of an alloy steel with a high hardness and no deformation. Parameters such as speed and dough thickness are easy to read on the screen and easily adjusted.

The material feeder is equipped with an automatic tensioning device and automatic deviation rectifying device to ensure reliable conveyance. The roller and groove roller are made of an alloy steel with a high hardness and no deformation. Parameters such as speed and dough thickness are easy to read on the screen and easily adjusted. - Tunnel oven

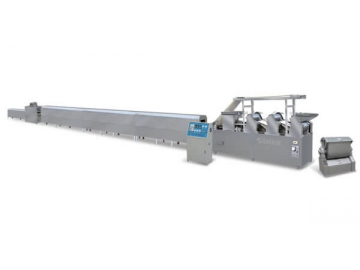

We provide a variety of tunnel ovens for the production of different biscuit types. Oven types include a hot air circulating oven, wood or gas fired oven, and an infrared oven. The tunnel oven features a modular design, with the number of modules dependent on the production line capacity.

We provide a variety of tunnel ovens for the production of different biscuit types. Oven types include a hot air circulating oven, wood or gas fired oven, and an infrared oven. The tunnel oven features a modular design, with the number of modules dependent on the production line capacity.

Oil spray machine

The oil spray machine carries out a high speed, foggy oil spray on biscuits to improve luster, flavor and taste. The oil tank is warmed via electric heated water and an adjustable temperature. The oil spray machine uses a filter to recycle used oil after spraying, and is made of 304 stainless steel for an excellent cleanliness and hygienic performance.

- Condiment spreader

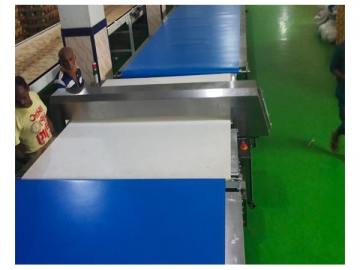

- Cooling conveyor system

- Biscuit stacker

The biscuit stacker uses a star wheeled structure for a fast stacking process.

The biscuit stacker uses a star wheeled structure for a fast stacking process. - Rotary molder

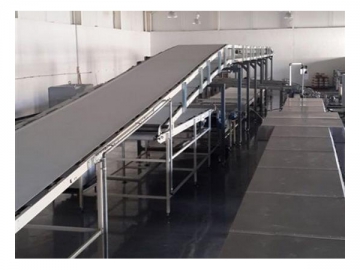

- Furnace charging conveyor

- Turning conveyor

- Biscuit mold

Related products

Send Message

Most Recent

More

Other Products

Videos