MBR Membrane Modules

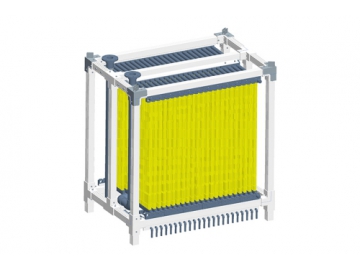

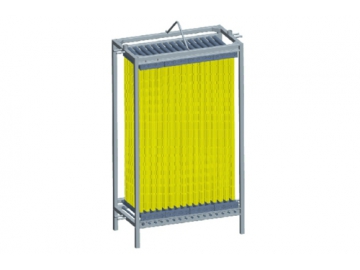

Membrane bioreactor module, or MBR module, is a wastewater treatment unit consisting of MBR membranes, outlet water pipe, aeration pipe and module frame. MBR modules are mostly immersed directly in the reactor tank without the need for pressure vessel, which are known as submerged membrane bioreactor (SMBR) or immersed membrane bioreactor (IMBR). MBR module frame is constructed with robust 304/316 stainless steel or FRPP material, featuring excellent corrosion resistance and high durability. Our MBR modules are available in single-deck and double-deck configurations, and arranged in single row or multiple rows.

- Applications

- Features

- Parameters

- Models

- Upgrading and retrofitting of existing wastewater treatment plants;

- Domestic wastewater treatment for urban and rural areas;

- Sewage treatment for medical and livestock fields;

- Industrial wastewater treatment for pulp & paper, pharmaceutical, printing & dyeing, chemical fiber, food & beverage, electroplating, etc.;

- Membrane bioreactor module can perform high efficiency solid-liquid separation process, producing high quality effluent with near-zero turbidity and suspended solids for direct reuse, thereby achieving wastewater recycling purpose.

- MBR membranes feature very high rejection rate which means virtual retaining of all microorganisms within the reactor, and enabling completely independent hydraulic retention time (HRT) and sludge retention time (SRT), which can be easily and flexibly controlled.

- The MBR membrane module affords higher efficiency of nitrogen and phosphorus removal.

- The biological reactor operates at high volumetric loading rate with long sludge retention time (SRT) to keep the excess sludge production to a minimum.

- With the utilization of membrane bioreactor module, the wastewater treatment plant can eliminate the requirement for sedimentation tank, greatly saving space and investment cost.

- Coupled with PLC system, the MBR membrane modules can be automatically controlled.

| Raw Wastewater Parameters | |

| Water source | Municipal wastewater, residential sewage, catering wastewater, industrial wastewater, mining wastewater, chemical wastewater |

| PH | 2-12 |

| Max. sludge concentration | 15000ppm |

| Max. particle size | ≤2mm |

| FOG content (fat, oil, and grease) | <2mg/L |

| BOD | <400mg/L |

| NH3-N | <50mg/L |

| Treated Water Parameters | |

| Suspended solids | <1mg/L |

| SDI | <3 |

| Turbidity | <0.5NTU |

| Coliform organisms | 100/100ml |

| NH3-N | <50mg/L |

| Operational Parameters | |

| Filtration | Negative pressure filtration |

| Cleaning | Air flushing, backwashing |

| Working temperature | 5-45°C |

| Suction pressure | 0.01-0.05Mpa |

| Max. transmembrane pressure (TMP) | 0.05Mpa |

| NH3-N | <50mg/L |

If you can not find what you are looking for, please contact us for customization.

Discover our range of membrane modules from the following. If you can not find what you are looking for, please contact us for customization.

| Model | Module frame length (spacing 65mm) | Module frame length (spacing 85mm) | Module frame width | Module frame height | Design production | Total area | Outlet | Inlet | Aeration rate |

| LF1000-12W-20 | 785mm | 965mm | 1280mm | 1060mm | 3.0m³/h | 200m² | DN40 | DN40 | 60m³/h |

| LF1000-12W-24 | 915mm | 1135mm | 3.6m³/h | 240m² | DN50 | DN50 | 72m³/h | ||

| LF1000-12W-28 | 1045mm | 1305mm | 4.2m³/h | 280m² | 84m³/h | ||||

| LF1000-12W-32 | 1175mm | 1475mm | 4.8m³/h | 320m² | DN65 | DN65 | 96m³/h | ||

| LF1000-12W-36 | 1305mm | 1645mm | 5.4m³/h | 360m² | 108m³/h | ||||

| LF1000-12W-40 | 1435mm | 1815mm | 6m³/h | 400m² | 120m³/h | ||||

| LF1000-12W-44 | 1565mm | 1985mm | 6.6m³/h | 440m² | 132m³/h | ||||

| LF1000-12W-48 | 1695mm | 2155mm | 7.2m³/h | 480m² | DN80 | DN80 | 144m³/h | ||

| LF1000-12W-52 | 1825mm | 2325mm | 7.8m³/h | 520m² | 156m³/h | ||||

| Module frame material | Optional: stainless steel SS304 (I), SS316 (II) | ||||||||

| Raw water quality parameters | Max. particle size: < 2mm FOG content (fat, oil, and grease): ≤2mg/L Max. sludge concentration: 10000mg/L | ||||||||

| Backwashing and testing conditions | Suction pressure: < 0.05 Mpa Max. backwashing water pressure: 0.1Mpa Max. testing air pressure: 0.1MPa | ||||||||

| Model | Module frame length (spacing 65mm) | Module frame length (spacing 85mm) | Module frame width | Module frame height | Design production | Total area | Outlet | Inlet | Aeration rate |

| LF1000-11W-4 | 395mm | 455mm | 620mm | 1060mm | 0.6m³/h | 40m² | DN25 | DN25 | 12m³/h |

| LF1000-11W-6 | 525mm | 625mm | 0.9m³/h | 60m² | 18m³/h | ||||

| LF1000-11W-8 | 655mm | 795mm | 1.2m³/h | 80m² | 24m³/h | ||||

| LF1000-11W-10 | 785mm | 965mm | 1.5m³/h | 100m² | DN32 | DN32 | 30m³/h | ||

| LF1000-11W-12 | 915mm | 1135mm | 1.8m³/h | 120m² | 36m³/h | ||||

| LF1000-11W-14 | 1045mm | 1305mm | 2.1m³/h | 140m² | DN40 | DN40 | 42m³/h | ||

| LF1000-11W-16 | 1175mm | 1475mm | 2.4m³/h | 160m² | 48m³/h | ||||

| LF1000-11W-18 | 1305mm | 1645mm | 2.7m³/h | 180m² | 54m³/h | ||||

| LF1000-11W-20 | 1435mm | 1815mm | 3.0m³/h | 200m² | 60m³/h | ||||

| Module frame material | Optional: stainless steel SS304 (I), SS316 (II) | ||||||||

| Raw water quality parameters | Max. particle size: < 2mm FOG content (fat, oil, and grease): ≤2mg/L Max. sludge concentration: 10000mg/L | ||||||||

| Backwashing and testing conditions | Suction pressure: < 0.05 Mpa Max. backwashing water pressure: 0.1Mpa Max. testing air pressure: 0.1MPa | ||||||||

| Model | Module frame length (spacing 65mm) | Module frame length (spacing 85mm) | Module frame width | Module frame height | Design production | Total area | Outlet | Inlet | Aeration rate |

| LF1500-12W-20 | 785mm | 965mm | 1280mm | 1880mm | 6.0m³/h | 400m² | DN50 | DN50 | 84m³/h |

| LF1500-12W-24 | 915mm | 1135mm | 7.2m³/h | 480m² | DN65 | DN65 | 100.8m³/h | ||

| LF1500-12W-28 | 1045mm | 1305mm | 8.4m³/h | 560m² | 117.6m³/h | ||||

| LF1500-12W-30 | 1110mm | 1390mm | 9m³/h | 600m² | 126m³/h | ||||

| LF1500-12W-32 | 1175mm | 1475mm | 9.6m³/h | 640m² | 134.4m³/h | ||||

| LF1500-12W-36 | 1305mm | 1645mm | 10.8m³/h | 720m² | DN80 | DN80 | 151.2m³/h | ||

| LF1500-12W-40 | 1435mm | 1815mm | 12m³/h | 800m² | 168m³/h | ||||

| LF1500-12W-42 | 1500mm | 1900mm | 12.6m³/h | 840m² | 176.4m³/h | ||||

| LF1500-12W-46 | 1630mm | 2070mm | 13.8m³/h | 920m² | DN100 | DN80 | 193.2m³/h | ||

| LF1500-12W-48 | 1695mm | 2155mm | 14.4m³/h | 960m² | 201.6m³/h | ||||

| LF1500-12W-52 | 1825mm | 2325mm | 15.6m³/h | 1040m² | 218.4m³/h | ||||

| LF1500-12W-56 | 1955mm | 2495mm | 16.8m³/h | 1120m² | 235.2m³/h | ||||

| Module frame material | Optional: stainless steel SS304 (I), SS316 (II) | ||||||||

| Aeration method | Optional: standard straight-line aeration pipe (i), coarse bubble diffuser (ii) | ||||||||

| Raw water quality parameters | Max. particle size: < 2mm FOG content (fat, oil, and grease): ≤2mg/L Max. sludge concentration: 10000mg/L | ||||||||

| Backwashing and testing conditions | Suction pressure: < 0.05 Mpa Max. backwashing water pressure: 0.1Mpa Max. testing air pressure: 0.1MPa | ||||||||

| Model | Module frame length (spacing 65mm) | Module frame length (spacing 85mm) | Module frame width | Module frame height | Design production | Total area | Outlet | Inlet | Aeration rate |

| LF1000-22W-76 | 1370mm | 1730mm | 1280mm | 1860mm | 11.4m³/h | 760m² | DN80 | DN80 | 228m³/h |

| LF1000-22W-84 | 1500mm | 1900mm | 12.6m³/h | 840m² | 252m³/h | ||||

| LF1000-22W-88 | 1565mm | 1985mm | 13.2m³/h | 880m² | DN100 | DN100 | 264m³/h | ||

| LF1000-22W-100 | 1760mm | 2240mm | 15m³/h | 1000m² | 300m³/h | ||||

| LF1500-22W-76 | 1370mm | 1730mm | 3660mm | 22.8m³/h | 1520m² | 266m³/h | |||

| LF1500-22W-80 | 1435mm | 1815mm | 24m³/h | 1600m² | 280m³/h | ||||

| LF1500-22W-84 | 1500mm | 1900mm | 25.2m³/h | 1680m² | 294m³/h | ||||

| LF1500-22W-88 | 1565mm | 1985mm | 26.4m³/h | 1760m² | 308m³/h | ||||

| LF1500-22W-96 | 1695mm | 2155mm | 28.8m³/h | 1920m² | 336m³/h | ||||

| LF1500-22W-100 | 1760mm | 2240mm | 30m³/h | 2000m² | 350m³/h | ||||

| Module frame material | Optional: stainless steel SS304 (I), SS316 (II) | ||||||||

| Aeration method | Optional: standard straight-line aeration pipe (i), coarse bubble diffuser (ii) | ||||||||

| Raw water quality parameters | Max. particle size: < 2mm FOG content (fat, oil, and grease): ≤2mg/L Max. sludge concentration: 10000mg/L | ||||||||

| Backwashing and testing conditions | Suction pressure: < 0.05 Mpa Max. backwashing water pressure: 0.1Mpa Max. testing air pressure: 0.1MPa | ||||||||

| Model | Module frame length (spacing 65mm) | Module frame length (spacing 85mm) | Module frame width | Module frame height | Design production | Total area | Outlet | Inlet | Aeration rate |

| LF1500-22P-72 | 1625mm | 1965mm | 1395mm | 3700mm | 21.6m³/h | 1440m² | DN80 | DN80 | 266m³/h |

| LF1500-22P-80 | 1755mm | 2135mm | 24m³/h | 1600m² | 280m³/h | ||||

| LF1500-22P-84 | 1820mm | 2220mm | 25.2m³/h | 1680m² | 294m³/h | ||||

| LF1500-22P-88 | 1885mm | 2305mm | 26.4m³/h | 1760m² | DN100 | DN100 | 308m³/h | ||

| LF1500-22P-96 | 2015mm | 2475mm | 28.8m³/h | 1920m² | 336m³/h | ||||

| LF1500-22P-100 | 2080mm | 2560mm | 30m³/h | 2000m² | 350m³/h | ||||

| Module frame material | Optional: FRPP plastic material (coupling bolt and lifting eye is selectable), stainless steel SS316L (II), duplex steel (III) | ||||||||

| Aeration method | Optional: standard straight-line aeration pipe (i), coarse bubble diffuser (ii) (frame height is 3790mm when coarse bubble diffuser is selected) | ||||||||

| Raw water quality parameters | Max. particle size: < 2mm FOG content (fat, oil, and grease): ≤2mg/L Max. sludge concentration: 10000mg/L | ||||||||

| Backwashing and testing conditions | Suction pressure: < 0.05 Mpa Max. backwashing water pressure: 0.1Mpa Max. testing air pressure: 0.1MPa | ||||||||