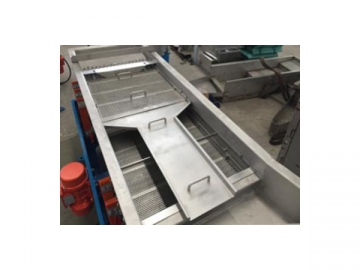

Vibrating Classifier

Applications

Our vibrating classifier is machinery designed to screen raw material particles using a three-layer composite screen structure. The materials are filtered through the equipment three times with excellent screening accuracy. The mesh range is 2mm-10mm and it can be used to screen various masterbatches, engineering plastics, and rubber materials.

| Grade | |||||||

| Nominal Throughput (kg/h) | 500 | 800 | 1000 | 2000 | 3000 | 6000 | 8000 |

| Capacity (kg/h) | 500-600 | 800-1000 | 1000-2000 | 2000-3000 | 3000-4000 | 6000-7000 | 8000-9000 |

| Size (mm) | 500*2400 | 500*2800 | 700*2800 | 800*3200 | 900*3600 | 1200*3800 | 1200*4200 |

| Inlet Height (mm) | 900 | 900 | 900 | 900 | 1100 | 1300 | 1300 |

| Outlet Height (mm) | 600 | 600 | 600 | 600 | 800 | 1000 | 1000 |

| Motor Power (Kw) | 0.05 | 0.05*2 | 0.16*2 | 0.25*2 | 0.37*2 | 0.55*2 | 0.75*2 |

| Reciprocating Range (mm) | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 |

Operational Principle

The vibrating classifier takes advantage of the exciting force of its vibration motor to drive the sieve surface vibration in a certain direction. The vibration of the screen that is connected with the base is vibrated, and the sieve surface is supported by the flat spring structure to ensure that the screen is always vibrating horizontally.

- The device realizes stable oscillation back and forth under the natural frequency, which adopts the double-mass resonance structure. There is no turbulence in the box, so it can vibrate without cracking for continuous use.

- The resonance classifier can realize the smooth migration of material on the screen without the phenomenon of long particles bouncing and leaking because of the steady and adjustable vibration velocity and amplitude.

- The material has been screened three times and the screening accuracy is high due to its three layers of composite screen structure.

- We provide a single type sieve plate with 12 different mesh types, such as 2.0-10.0mm. It can be flexibly changed according to the size of different pelletizing sizes to ensure that each product can achieve the best screening efficiency.

- The sieve plate is fixed with an anti-loose quick clamp, which can be removed quickly in 1 minute and cleaned in 5 minutes.

Index

granule separation, vibrating classifier, sieving machine