DA58T Electro Hydraulic Bending Press Brake

Application

The DA58T electro hydraulic bending press brake is primarily used for the bending and processing of stainless steel, iron, copper and aluminum, and features a high production efficiency and bending accuracy. The DA58T electro hydraulic bending press brake uses upper and lower molds in different shapes, so that metal can be bent into various shapes. Through the use of a single sliding stroke, the material is quickly bent into shape, and the workpieces with complicated shapes can be made by multiple bending.

The DA58T electro hydraulic bending press brake can be widely used in the aviation industry, light industry, metallurgical industry, chemical industry, architecture industry, shipbuilding industry, auto industry, power industry, electric appliance industry and decoration industry.

Parameters| Model | Bending Pressure (Kn) | Bending Length (mm) | Column Distance (mm) | Throat Depth (mm | Slider Stroke (mm) | Max. Opening Height (mm) | Yl,Y2-axis Down Speed (mm / sec) | Yl,Y2-axis Back Stroke Speed (mm / sec) | Y1,Y2- axis Precision (mm) | X-axis Max Distance (mm) | Workpiece Linear Degree (mm/m) | X&R Axes Accuracy (mm) | Sliding Front Supporting Stopper Arms (PCS) | Back Stopper (PCS) | Main Motor (Kw) | L*W*H(mm) | Weight (T) |

| 63T/1300 | 630 | 1300 | 950 | 350 | 100 | 340 | 150 | 150 | 0.01 | 500 | >0.3 | 0.05 | 2 | 2 | 5.5 | 3100*1450*2050 | 4 |

| 63T/2500 | 630 | 2500 | 1900 | 350 | 170 | 380 | 150 | 150 | 0.01 | 500 | >0.3 | 0.05 | 2 | 2 | 5.5 | 3100*1450*2050 | 5.8 |

- Netherlands DELEME CNC system specialized for DA58T metal bending press brake

- Electro-hydraulic proportional valve controls the synchronization

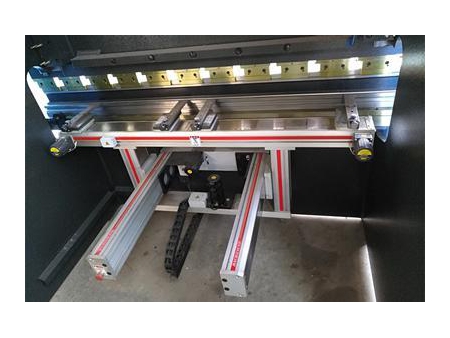

- The back gauge equips the Taiwan HIWIN ball screws & linear guide; The stroke is 500mm; Programming can be the 0.01mm; Programming realize the self-recovery

- Automatic hydraulic pressure gauge pressurization

- Korea KACON foot switch

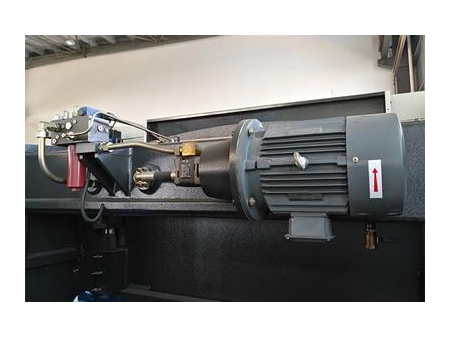

- America SUNNY internal gear pump with high-performance and low noise

- Germany EMB tubing connector

- Germany Busak Shamban sealing element

- France Schneider Electrics

- Germany Siemens main motor and France Schneider frequency changer

- Spain FAGOR raster with high precision

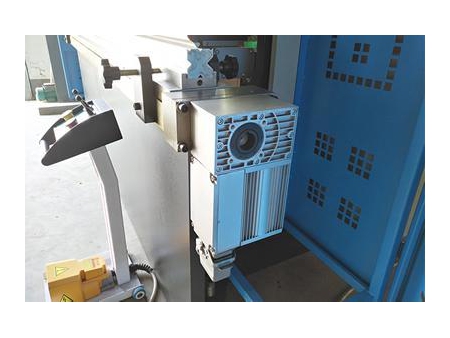

- Estun dual servo motor

- Germany Bosch-Rexroth hydraulic system

- Standard configuration 4+1 axises: Y1-Y2-X-R-V

DA58T CNC system

1. 2D touching graphical programming

2. 15''high definition TFT real color display

3. Bending procedures calculation

4. Deflection compensation control

5. Servo and frequency changer control pattern

6. The advanced Y axis control arithmetic not only controls the closed loop valve, but also controls the open loop valve

7. USBconnector

Germany Rexroth or America First hydraulic system; Compact structure; High quality

By using the Siemens electric machine, the service life of the electric bending press brake is increased, as well as decreases the noise levels of operation.

America SUNNY internal gear pump with well oil absorption and reliable performance

Back gauge dual servo motor controls the X axis and R axis

Heavy load linear guide rail guiding, large lead ball screws transmission, high accuracy, fast speed and good stability

Aluminum alloy material

Quickly clamping device

European style mold clamp connector

Using a fine-tune wedge block can adjust the effective usage height of the clamp to ensure the flatness among the clamps.

V axis; Mechanical compensation

The DA58T electro hydraulic bending press brake contains different 3D surfaces with different slops, thus compensation for blind zones within traditional hydraulic systems. The compensation curve of the machine is closer to a sliding plate deformation curve, and improves upon the process accuracy of the DA58T electro hydraulic bending press brake.

A KACON foot switch, manual adjustment and emergency stop switch button ensures operation security.

Other optional configuration for the DA58T electro hydraulic bending press brake:

Amada quick clamp

Amada quick clamp  Front photoelectric protection

Front photoelectric protection  Italy DSP laser protection

Italy DSP laser protection

Jiashida is a sheet metal fabrication equipment manufacturer and supplier, offering all kinds of sheet metal metalwork machinery like hydraulic shear, press brake, punch press, plate roll bender and sheet metal shears, metal benders. We have well trained and experienced team and fully equipped machining equipment to guarantee that we offer good quality metalworking machines.

Index

sheet metal press brake, metal bending equipment, metalworking equipment