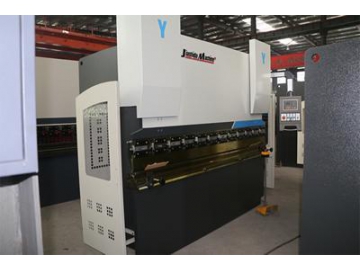

4-Axis Hydraulic CNC Sheet Metal Press Brake

ACCURL® design innovations are based on years of experience and have resulted in the Smart Fab B Series CNC hydraulic press brakes which allow for faster bending, and a better return and back gauge. Accurl CNC press brakes will allow you to mass produce precision parts effectively while decreasing the cost per part.

Stronger, faster and deeper bends:

Euro Pro B Series hydraulic CNC press brake bending machines allow users to increase their production capacity and prevent production time loss.

General Features:

● Chrome coated cylinders are machined with 0.001 mm precision and pistons are specially hardened.

● Original clamps are user friendly and machined with high precision.

● Front support arms are slideable along the machine length and easy to adjust.

● Compact Bosch-Rexroth hydraulics are produced according to CE standards.

● Two photocells on sides for rear guard.

● Fast tool tightening.

● Optic linear scales are sensitive up to ± 0,01 mm.

● by CNC controller, foldable back gauge fingers for reverse bending applications.

● Multifunctional and highly programmable, DELEM DA58T CNC controller.

● SIEMENS/SCHNEIDER electrical system.

● Automatic axis referencing when machine is turned on.

● Standard side guard that meets CE regulations

● Synchronized working cylinders will give you the best bending result with its perfect repeatability ratio.

● 2 axis ultra strong backgauge system (X=800 mm and R), with ± 0,01 mm. repeatability, moves along rails and ball screw, bending length controlled

Standard Equipment:

● Height adjustable and movable sliding front support arms.

● DELEM DA58T 2D graphical controller with PC-Profile-T 2D software.

● Promecam easy clamping system.

● 410 mm throat depth.

● 4 plus 1 axis CNC:

-Y1, Y2 precision ram positioning.

-X, R precision servo-driven back gauge.

-Manually adjustable Z1, Z2-axis.

-CNC motorized wave crowning.

● 2 back gauge fingers

● Covers for cylinders and top beam

● Top and bottom tools are surface hardened by special treatment.

● CNC controlled strong X=800 mm back gauge

● Foot pedal is produced according to CE standards and suitable for single and multiple bends.

● 2 photocells are placed facing each other for rear guards.

● Preadjusted electrical requirements based on customer's geographical area.

● The electrical panel with a cooling system is designed to meet CE standards & is composed of both automatic and electrical Siemens equipment.

| Model(SMART FAB) | B1560 | B2580 | B32110 | B32135 | B32175 | B40175 | B32220 | ||

| Bending force | KN | 600 | 800 | 1100 | 1350 | 1750 | 1750 | 2200 | |

| Bending Length | mm | 1500 | 2500 | 3200 | 3200 | 3200 | 4200 | 3200 | |

| Between Columns | mm | 1100 | 2060 | 2700 | 2700 | 2700 | 3700 | 2700 | |

| Daylight | mm | 405 | 405 | 430 | 430 | 430 | 430 | 430 | |

| Slide Stroke | mm | 200 | 200 | 200 | 200 | 200 | 200 | 200 | |

| Throat Depth | mm | 370 | 400 | 400 | 400 | 400 | 400 | 400 | |

| Bolster Width | mm | 80 | 80 | 100 | 100 | 100 | 100 | 140 | |

| Down Speed | mm/min | 200 | 200 | 180 | 180 | 160 | 160 | 160 | |

| Pressing Speed | mm/min | 8 | 8 | 10 | 10 | 10 | 10 | 10 | |

| Return Speed | mm/min | 180 | 180 | 150 | 150 | 150 | 150 | 140 | |

| Back Gauge Stroke | mm | 500 | 600 | 800 | 800 | 800 | 800 | 800 | |

| Outline Size | L | mm | 1825 | 2825 | 3500 | 3550 | 3500 | 4500 | 3500 |

| W | mm | 1650 | 1650 | 1650 | 1650 | 1650 | 1650 | 1730 | |

| H | mm | 2300 | 2350 | 2650 | 2700 | 2700 | 2750 | 2900 | |

| Weight | kg | 4600 | 5600 | 8000 | 9500 | 10000 | 12000 | 13200 | |

The best bending results. Users can bend longer and deeper parts using the standard Smart Fab B Series!

Detailed Pictures- DELEM DA58T 2D graphical controller

- Euro standard sectioned top and 4V-Die bottom tools

- Servo hydraulic system

- The Back light safety guards (category-4)

- Laser protection system for die area