JDS-180/240 Rotary System Pouch Packaging Machines

The JDS-180/240 series rotary system pouch packaging machines offer flat bottom bags, including corner spout, top spout, zipper and standard. This packaging machine is designed to package solids, liquids, pastes and powders, including dairy products, juice, jam, coffee grounds and pharmaceutical products.

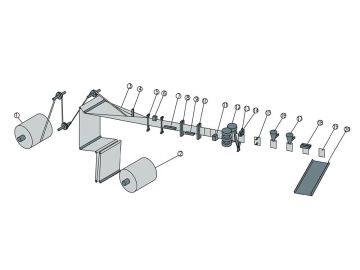

1. Zipper Release

2. Film Unwind

3. Bag Forming

4. Zipper Guide

5. Film Guide

6. Photocell

7. Bottom Zipper Seal

8. Vertical Zipper Seal

9. Bottom Seal

10. Vertical Seal

11. Tear Notch

12. Servo Advance

13. Cutting

14. Pouch Catching

15. Pouch Opening

16. Filling Ⅰ

17. Filling Ⅱ

18. Top Seal

19. Finished Product

20. Product Outlet

| Type | Minimum Bag Size (mm) | Maximum Bag Size (mm) | Packing Capacity (ml) | Packing speed (ppm) | Power (kw) | Gas consumption (NL/min) | Weight (kg) | Equipment Size (mm) |

| JDS-180 | 60*80 | 180*230 | 500 | 50-70 | 4 | 0.25 | 2000 | 3800*1300*1500 |

| JDS-240 | 60*80 | 180*230 | 800 | 50-70 | 4 | 0.25 | 2000 | 400*1300*1500 |

· Independent Film Unwind Unit

· Better doypack forming

· Ensure good control of film tensile force

· More flexible, suitable for different pouch specifications

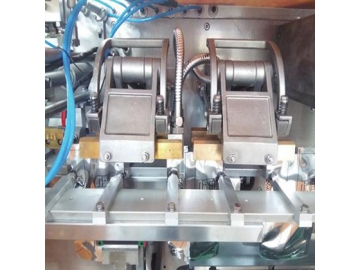

· Dual Filling Station

· Reduce filling time by half

· Improved filling accuracy

· Fill 2 products simultaneously

· 2 Top Seal Unit

· Ensure seal strength, no leakage

· Even seal with good appearance

· Higher adaptability of film material