Instant Noodle Machines

Similar to how pasta dishes are well-liked in Europe, the popularity of instant noodles in Asia is no mystery. In recent years, instant noodles are becoming more prevalent among consumers across continents around the world, this is partly because they offer several benefits such as easy-to-carry, long shelf-life and ready-to-cook convenience, and they are also affordable as well.

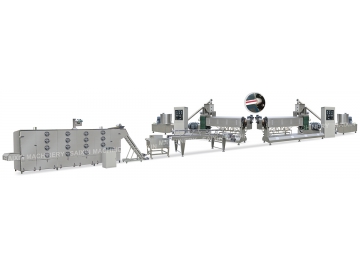

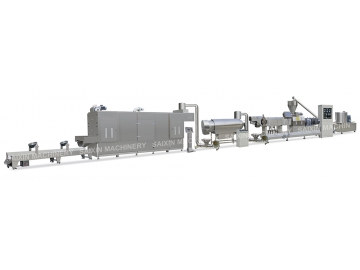

By embracing original concepts and technological innovation, Dongfang Noodle as an instant food machine manufacturer has been developing and manufacturing a full line of instant noodle machines over the years. Dongfang Noodle designs and manufactures not only a wide range of individual machines for instant noodle production, but also a complete instant noodle production line. Over the past 50 years, we have provided a number of instant noodle makers and noodle plants with commercial noodle machines that are precisely oriented to their requirements of instant noodle making.

-

Brine Mixer

Designed to prepare, cool and store brine solution, the brine mixer consists of a mixing barrel, agitator, heating tube, liquid pipe and feed liquid pump . It is used to prepare mixed liquids such as salt, alkali, additives and water required for dough mixing. Adopting brine mixer provides quick and simple producing of homogenous brine, without deposits with the use of dry substances.

-

Vibrating Sieve

Pour the raw materials that need to be sieved into the center of the sieve. Through constantly vibrating the screen, some impurities in the raw materials are eliminated.

-

Dual-axis Flour Mixing Machine

The flour mixing machine is used for mixing and stirring flour and water. Dough mixing is the process of stirring flour and brine mixture in a certain proportion, so that the protein and starch in the flour absorb water and swell to form a flocculent dough. The flour mixer adopts a double-shaft structure, and the stirring paddle is in a spiral shape on the shaft. The two shafts rotate in opposite directions, so that the flour can fully absorb water and be uniform.

-

Dough Ripening Conveyor

The dough ripening conveyor is used to manage the dough aging process after the dough mixing stage for your instant noodles. Maintaining constant temperature and humidity, the dough moves forward slowly with the conveyor belt in a static state , and achieves ripening naturally. When the dough reaches the end of the conveyor belt, the bar on the crushing device breaks the dough that may agglomerate into small pieces, and then falls into the hopper of the roller. The scraper sweeps off the dough stuck to the belt.

-

Noodle-Sheet Press Roller with 4-Axis Feed

The new type pressing roller adopts an integral structure, which consists of a feeding hopper, a feeding shaft, multiple groups of pressing rollers and the roller cutter. The feeding shaft adopts four axis to make the feeding process continuous and uniform. The flour passes through the first group of roller to form a dough sheet, then the dough sheet is continuously rolled by the roller, and finally the dough sheet is rolled to be a suitable thickness, which has the characteristics of smoothness and stiffness. Made using alloy materials, each group of new pressure rollers adopts an individual motor, and features an inverter to control motor speed. In addition, the photoelectric tracking technology is used to automatically adjust the speed of the dough sheet conveying. The dough sheet is automatically fed by a belt conveyor. Adopting automatic control greatly improves production efficiency and reduces labor costs. The rear section of pressing roller is designed with a roller cutter and a forming device that makes the noodles become wave-shape. After the dough passes through the cutting and forming device, the noodles are cut to the appropriate width and made into a wave shape.

-

Multi-Layer Noodle Steamer

The wave-shaped noodles are conveyed into the steamer with a wire mesh conveyor belt, which are gelatinized by steam heating to finalize the noodle shape. The steaming chamber adopts a water-sealing structure to ensure that the steam does not leak. The upper cover can be lifted and lowered as a whole, which is convenient for cleaning. The mesh belt is made of stainless steel, which is safe and hygienic. Three-layer structure covers a small area.

-

Noodle Cutting Machine

This noodle machine is used to cut the steamed wave-shaped noodles quantitatively, and then transport the noodle blocks to the noodle box of the fryer. Before cutting, the noodles are cooled by axial fan and sprayed by spraying device , and then stretched three times. Noodles become loose and are easy to shape. The speed of the cutter can be adjusted.

-

Noodle Shaping Machine

The noodles falling into the noodle boxes are air-dried and shaped to make the noodle block even and flat.

-

Fryer

This noodle frying machine is used to fry the cut and formed noodle blocks at high temperature, so that they can be quickly dehydrated and dried to form crispy instant noodle blocks. The noodle fryer is divided into two zones, front and back . With self-controlled temperature, the color of the fried noodle blocks is uniform.

-

Stainless Steel Cooking Oil Tank

In addition to storing cooking oil in the hydraulic system, the stainless steel cooking oil tank also plays the role of heat dissipation, separation of air bubbles in the oil, precipitation of impurities, and continuous oil supply.

-

Multi Layer Noodle Drying Machine

This noodle dryer is the latest type in the recent years, which adopts hot air drying technology. It provides improved air flow rate and drying temperature, also can ensure relative stability of noodle cakes, without shifting. With maximum temperature of up to 150 ºC, the scientific hot air circulation system makes full use of the heating energy, greatly improving the baking effect. There are two zones, first zone featuring 3 layers with a height of 18m, and second zone featuring 5 layers with a height of 18m, include below two layer is cooling 9 mins . In general, drying time reaches about 40 minutes. The moisture content of non-fried instant noodles is less than 10%, which is less than that of fried instant noodle.

-

Automatic Noodle Arranging Machine

Make the fried noodle blocks fall off from the noodle boxes, and separate the noodle scraps from the noodle blocks. The noodle blocks are arranged in many orderly rows and transported to the noodle cooling machine.

-

Noodle Cooling Machine

Designed with multiple fans in the noodle cooling machine, the fried high-temperature noodle blocks are quickly cooled to room temperature, which prevents the noodle blocks from getting moisturized to prepare for the instant noodle packaging process.

-

Check Conveyor for Noodle Blocks

The noodle blocks are conveyed vertically, and only one noodle block is allowed to pass at a time, which is convenient for manual or automatic inspection and adjustment.

-

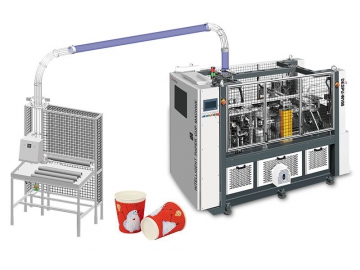

Noodle Packing machine

Various types of packaging can be made by this noodle packing machine in a continuous and automatic manner. The finished instant noodle blocks can be packaged with paper cups/bowls, plastic bags, etc.

-

Electric Control Panel

The electric control panel is used as the main control of our instant noodle production lines.