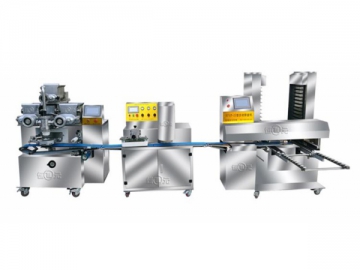

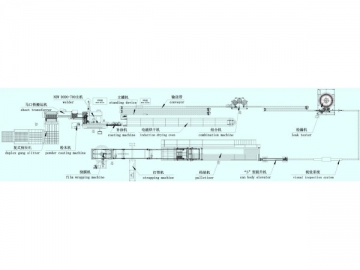

Mooncake Production Line

Our Mooncake Production Line is mainly used for producing moon cakes of various sizes. It is made up of a multifunctional stuffing filling machine, moon cake forming machine and automatic tray arranging machine, applicable to moon cake production lines.

Processing line details display

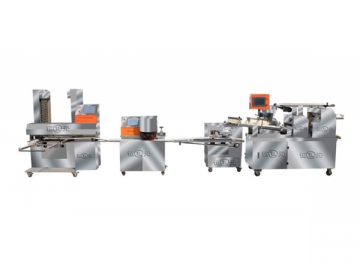

Feed filling through the stuffing hopper and put dough wrappers form the other side. If you are filling stuffings into your cakes, the middle hopper is used to feed another stuffing.

Stuffing filling.

To be rounded with moon cake forming machine.

Mold can be replaced via moon cake forming machine to obtain the shape and pattern you want. (the mold can be customized)

Enters tray arranging machine through conveying belt.

Tray arranging

This machine can adapt to different fillings, including solid fillings like whole peanut, nuts and crystal sugar, as well as liquid filling such as jam, chocolate, etc.

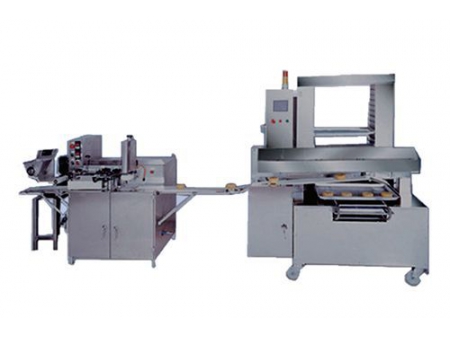

This machine is utility model of food machinery in various pasta manufacturers. It greatly saves labor, thus reducing the production cost and bringing good economic benefits to enterprises. It is suitable for large, medium and small moon cake producers.

This high speed automatic tray arranging machine is applicable to food enterprises with mass production capabilities. This machine can avoid damage or pollution caused by manual operation before baking to meet the food hygiene standards. The arranging numbers, moon cake size and parameters (columns and rows) can be set based on customer requirements (customers should provide the baking tray sizes). It will automatically put the moon cakes into the trays.

| Overall size (L x W x H) | 4100x890x1700mm |

| Output | 1000-6000 pcs/h |

| Equipment power | 4.8kw |

| Equipment weight | 1150kg |

| Equipment voltage | 220/380V |

| Finished product weight | 10-300g/pc (special size can be customized) |

| Equipment frequency | 50HZ/60HZ |

| Ratio of wrapper and stuffing | adjustable |

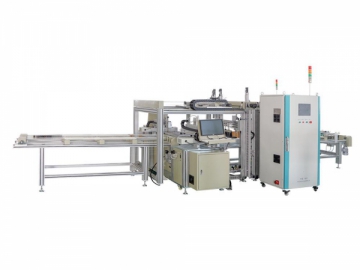

- Each food machine is controlled by PLC, making each process convenient to operate.

- Produced filling cakes can be arranged in the trays with two arranging modes. They are in parallel arrangement and cross arrangement, meeting requirements from different customers.

- All parts coming into contact with food adopt 304 stainless steel and food grade plastics to ensure the food safety and hygienic.

- The control system has its own memory function to memorize parameters of different products. During the production, the parameters can be directly used without re-setting, saving time.

- We can customize the tray arranging machines following customer requirements (customers should supply the baking tray sizes). This avoids trays replacing in large quantities after purchasing the equipment.