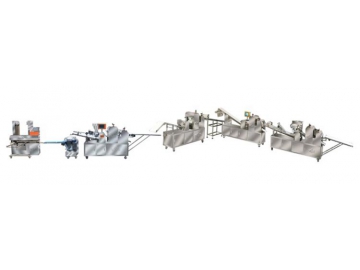

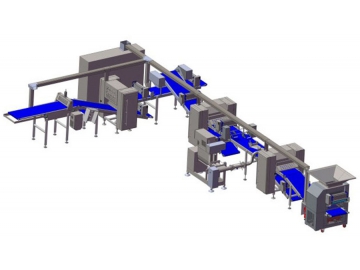

Puff Pastry Processing Line

The automatic puff pastry processing line is primarily applied in large production lines for bakeries and other food producers. It is suitable for a number of puff pastry doughs, hand tear breads, automatic pastry fillings, etc. It is mainly made up of a conveying system, dough pre-presser, dough roller sheeter, stuffing filling machine, pastry encrusting machine, dough folding machine, etc. The entire production line can be customized based on product quality and output.

Put the kneaded dough on the conveyor belt.

Through pre-pressing, the dough is pressed into neat dough sheet, then entering the three roll dough sheeter for initial pre-pressing.

Dough sheet encrusted by pastry.

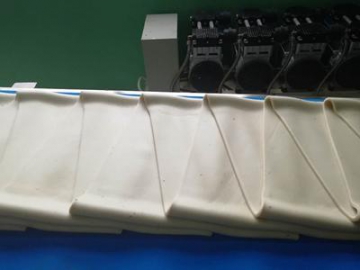

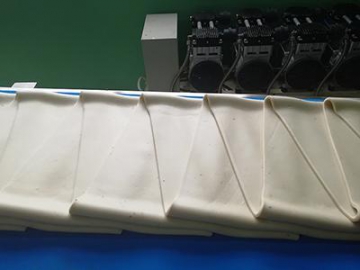

The pastry encrusted dough sheets enter the three roll dough sheeter to be rolled into neat sheets

First dough sheet folding.

Dough folding process.

Put the folded dough into the three roll dough sheeter again to be rolled and thinned.

Rolling process.

Dough re-folding.

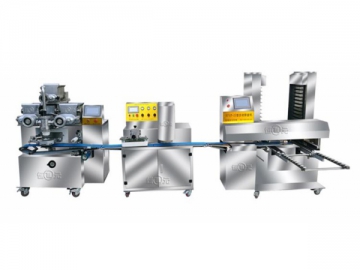

Bread machine, pastry machine and other machines can be added to produce different products based on demands.

Entering tray arranging

Conveying system

Automatic dough conveying system transports the dough slices to next process for high efficiency operation.

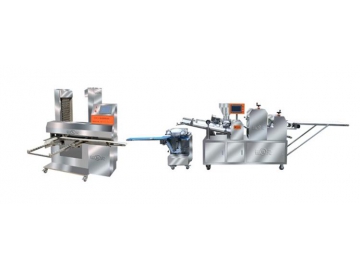

Pre-presser

The kneaded dough is conveyed to this pre-presser, it then is pressed into a neat dough sheet.

The dough sheet is rolled and extended through three roll dough sheeter and dough rolling device. Thus the sheet is glossier and more stable in quality. Each dough roller has thickness adjusting device used for setting sheet thickness. This aims to increase or reduce the product weight.

With multi feeding methods, the mixed stuffing is filled in the dough sheet and its essence is maintained to a maximum extent. This has no influence on the initial stuffing structure. The supplied fillings are diversified.

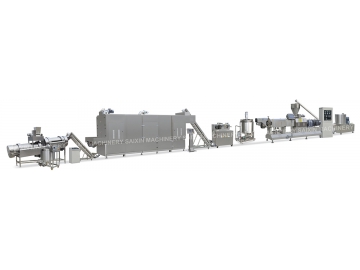

Pastry encrusting machine

It automatically encrusts the pastry into the dough sheet, safe and hygienic.

Dough sheet folding machine

It can automatically fold the pastry-filled dough sheets into neat sheets.

| Overall size (L x W x H) | 11000x800x1600mm |

| Output | 1000-20000 1000-2000pcs/h |

| Equipment power | 9.5kw |

| Equipment weight | 2500kg |

| Equipment voltage | 220/380V |

| Finished product weight | 10-200g/pc |

| Equipment frequency | 50HZ/60HZ |

- High output: this processing line can produce up to 20000 pastries per hour.

- This pastry processing line has uniform feeding speed, so the finished products are uniformly pastry filled.

- The whole processing line is equipped with a Japanese complete cutter set, German SIKE photoelectricity sensor, Taiwan drive motor, Taiwan inverter and Italy SAMPLA conveying belt. Thus the stability is ensured.

- The parts contacting with the food are made of high quality stainless steel, ensuring stable production, safety and hygiene.

- The operation is convenient and safe, only needing 2-3 person to operate.