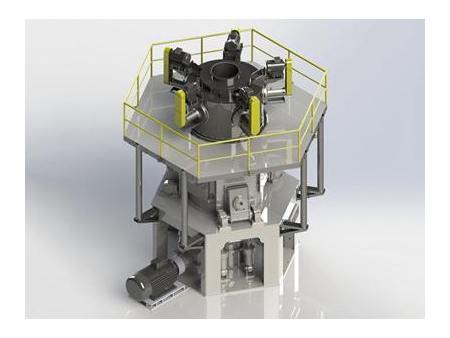

Application

VSCM series vertical coarse powder grinding mill is applicable to many kinds of materials and processing of non-metallic ore whose Moh's hardness is under 9 such as limestone mineral, marble mineral, barite mineral, dolomite mineral, talc, potash feldspar, fluorite, silica, gypsum, bentonite, kaolin and bauxite.

Parameters of vertical grinding mills of different types

VSCM-1100 vertical coarse powder grinding mill| Model | Processing ability(t/h) | Material moisture (%) | Material size(mm) | Finished material moisture (%) | Power (KW) |

| VSCM-1100 | 10~15 | ≤6% | < 8 | < 2% | 200~220 |

| Model | Processing ability(t/h) | Material moisture (%) | Material size(mm) | Finished material moisture (%) | Power (KW) |

| VSCM-1200 | 13~18 | ≤6% | < 10 | < 2% | 250~280 |

| Model | Processing ability(t/h) | Material moisture (%) | Material size(mm) | Finished material moisture (%) | Power (KW) |

| VSCM-1300 | 15~20 | ≤6% | < 12 | < 2% | 315~355 |

| Model | Processing ability(t/h) | Material moisture (%) | Material size(mm) | Finished material moisture (%) | Power (KW) |

| VSCM-1400 | 20~30 | ≤6% | < 20 | < 2% | 400~450 |

| Model | Processing ability(t/h) | Material moisture (%) | Material size(mm) | Finished material moisture (%) | Power (KW) |

| VSCM-1700 | 25~40 | ≤6% | < 24 | < 2% | 500~560 |

| Model | Processing ability(t/h) | Material moisture (%) | Material size(mm) | Finished material moisture (%) | Power (KW) |

| VSCM-2200 | 30~50 | ≤6% | < 30 | < 2% | 630~710 |

| Model | Processing ability(t/h) | Material moisture (%) | Material size(mm) | Finished material moisture (%) | Power (KW) |

| VSCM-3500 | 50~80 | ≤6% | < 36 | < 2% | 1120~1250 |

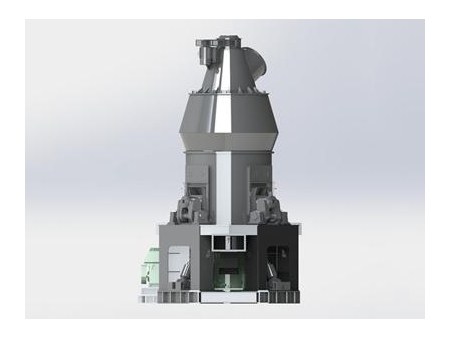

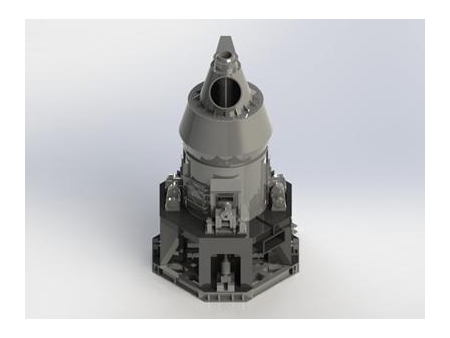

Product characteristics

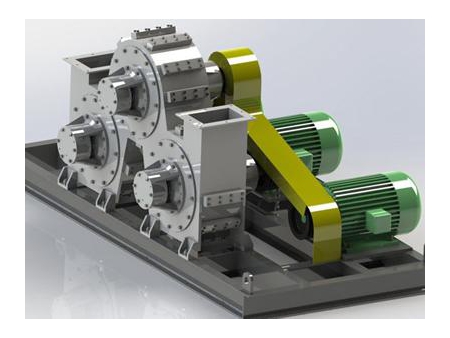

1. This kind of grinding roller mill features high efficiency, low power consumption and high production. Its production is 10%~20% higher than that of domestic ones of the same type. The energy saving effect even strengthens with the increase of moisture of the raw material.

2. Grinding with extrusion helps the powder granule form good shapes which is close to ellipse and has good fluidity.

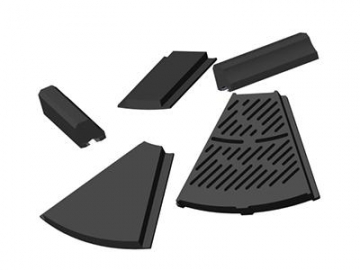

3. We adopt imported high chromium rare earth alloy steel. It features being wearable and can handle materials with high hardness.

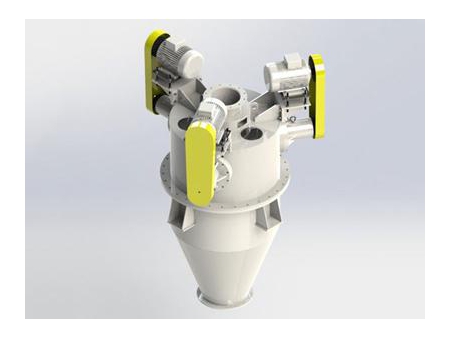

4. Vertical grinding mill integrates comminution, drying, grinding and transportation. It features compact layout. The area it covers is about 50%~60% of that of ball mill. The process flow is easy and it only occupies a small area.

5. The product has stable quality and wide application, including different industries such as cement, papermaking, desulfurization in power plant, coal powder preparation, building putty powder, ore slag and petroleum coke.

6. The roller and the grinding table don't have direct contact. So there is little vibration and noise. The noise within one meter's distance around the mill is about 80 decibels.

7. The grinding roller can be turned outside the vertical mill with the help of turning over roller equipment. The maintenance of the roller shell and the lining plate is easy and convenient.

8. The whole production line is a fully-enclosed cycle system. It operates under negative pressure air flow. There is little dust pollution and the production environment is clean and hygiene.

9. We adopt fully automatic PLC online control. The operation is stable and reliable.

10. Equipment faults can be detected online through remote monitor and control which allows for higher efficiency and speed.

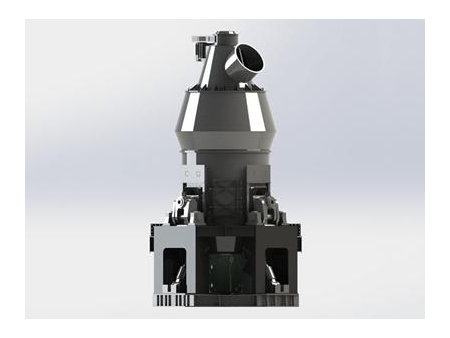

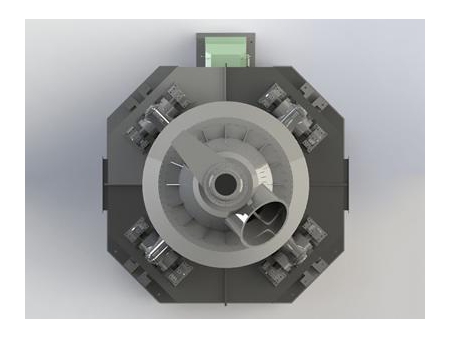

Working principal

VSCM series vertical coarse ultrafine powder ring rolling mil has a motor at the bottom that drives the grinding table and the materials are sent to the center of grinding table by the screw conveyor. The materials move to the outer edge of the grinding table under the effect of centrifugal force and form a special layer. When the materials pass through the gap between the roller and the grinding table, they are stricken, extruded and grinded by the roller thus are comminuted. After being grinded, the materials are taken upward by the strong air flow of the annular groove at the outer of the grinding table. Those materials which are coarser would fall in the grinding table and be grinded again while those smaller ones would rise in the hot air flow to the classifying system to be classified. Those which are qualified would be taken out of the classifying system by the air flow and taken into the dedust equipment. After being collected by the powder collecting machine, they become finished products. Besides, unqualified coarse powder would fall into the center of the grinding table for repeated grinding under the effect of the blades of the classifier rotors. The powder which has large granule would fall down to the lower shell for discharging through the air guide ring and be sent back to the feed bin.

Vsunny offers various industrial coarse powder grinding mill, and the complete equipment line that is for mineral crushing, grinding, classifying and separation. We can provide custom vertical mill equipment and solutions in client needs.