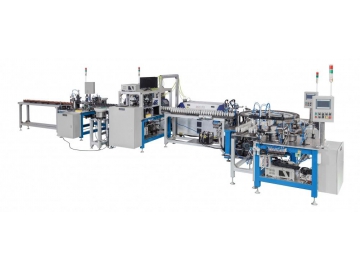

Headlight Assembly Line for H7 Halogen Bulb

The headlight assembly line for H7 halogenbulbs assembles H7 headlights by combining the halogen capsule bulb, metal cap, prefocus base and bulb holder. The entire line is made up of a headlight bulb focus adjusting machine, H7 halogen bulb metal cap mounting machine, pin welder, automotive light bulb head coating machine, and headlight bulb specification data inspecting machine. Considering the floor space of some customers, Fsfocus also designs this equipment with integrated focus adjusting and capping technology to minimize the size. In the welding of the prefocus ring and bulb holder, a laser beam welder is adopted. Because it has no contact with the materials, the focus adjusting precision is ensured.

Operator count: 2

Size: 10001X3853

Before capping, this halogen bulb mounting line will automatically identify the direction of the filament and make the right choice.

Parameters

| Device Name | Model | Power | Pressure | Production Capacity | Dimension(W×D×H) |

| H7 Halogen Bulb Mounting Line | AF-KMF016-H7 | 1.3 x 1 Kw/pcs | 0.6 Mpa | 1200-1440pcs/h | 1000cm×2100cm×1660cm |

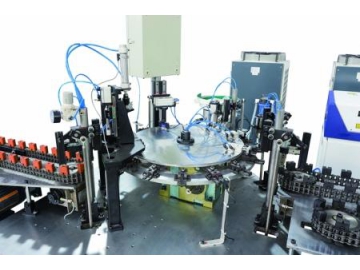

Traditional headlight bulb alignment machines adopt multi-station focus adjusting. Each headlight is focused at its own station. The H7 headlight bulb alignment machine uses the fixed-station focus adjusting. The headlights is focused at the same station one by one, which leads to more accurate focus than multi-station focusing.

Parameters

| Device Name | Model | Power | Pressure | Production Capacity | Dimension(W×D×H) | |

| H7 Headlight Bulb Alignment Machine | AF-DJF020-H7 | Main engine drive | 1.8 x 1 Kw/pcs | 0.6 Mpa | 1200-1440pcs/h | 1400cm×1400cm×1100cm |

| Laser beam welder | 18 x 2 Kw/pcs | 0.6 Mpa | 1200-1440pcs/h | |||

After focus adjusting, we will use the argon-arc welder to weld the pins. This not only minimizes costs but also ensures the welding quality. During the welding, we also perform air tightness testing to inspect whether the welding points are properly welded and the headlights are free of leaks.

Parameters

| Device Name | Model | Power | Pressure | Production Capacity | Dimension(W×D×H) | |

| H7 Pin welder | AF-HJF08-H7 | Main engine drive | 0.5 x 1 Kw/pcs | 0.6 Mpa | 1200-1440pcs/h | 800cm×800cm×1300cm |

| Argon-arc welder | 8.7 x 2 Kw/pcs | |||||

Fsfocus offers electric baking or fire baking type coating machines based on the actual demands of customers. The electric baked coatings feature stability and are not easily scraped off. But the fire baking machine is more energy-saving compared with the electric baking one.

Parameters

| Device Name | Model | Power | Pressure | Production Capacity | Dimension(W×D×H) | |

| H7-Automotive Light Bulb Head Coating Machine | AF-TTF100-H7 | Fire baking | 3.5 x 1 Kw/pcs | 0.6 Mpa | 1200-1440pcs/h | 1800cm×1900cm×1600cm |

| Electric baking | 28.5 x 1 Kw/pcs | |||||

Headlight bulb specification data inspecting machine is designed to test the parameters of h1, h2, h3, e, f and g, plus the measurement of cold resistance and power.

Parameters

| Device Name | Model | Power | Pressure | Production Capacity | Dimension(W×D×H) |

| H7-Headlight Bulb Specification Data Inspecting Machine | AF-FGF012-H7 | 0.5 x 1 Kw/pcs | 0.6 Mpa | 1200-1440pcs/h | 1100cm×1100cm×1050cm |

- High-end Headlamp Assembly line for H7 Halogen Bulb

Introduction

The high-end headlamp assembly line for H7 halogen bulbs comes equipped with an automotive light bulb head coating machine, headlight bulb specification data inspecting machine, and other outstanding equipment. The specification data inspecting machine can measure the parameters according to h1, h2, h3, e, f and g to ensure each produced headlight meets ECE regulations. We can also measure the cold resistance and power.Configuration

Headlight bulb adjusting focus machine, headlight bulb holder installing machine, light bulb pin welder, automotive light bulb head coating machine, headlight bulb specification data inspecting machine, cold resistance testerNote: Headlight bulb adjusting focus machine and headlight bulb holder installing machine can be integrated into the headlight bulb alignment machine.

- Economic Headlamp Assembly Line for H7 Halogen Bulb

Introduction

Economic high-end headlamp assembly line for H7 halogen bulb features simple structure and is able to complete the preliminary assembly of H7 headlight.Configuration

Headlight bulb adjusting focus machine, headlight bulb holder installing machine, light bulb pin welderNote: Headlight bulb adjusting focus machine and headlight bulb holder installing machine can be integrated into the headlight bulb alignment machine.