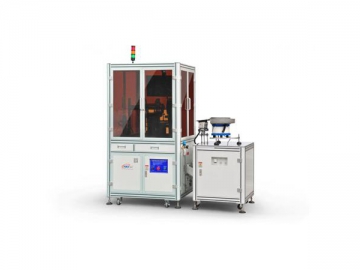

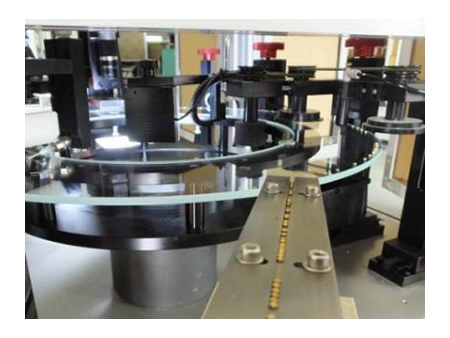

Automatic Nut/Rivet Optical Sorting Machine

Request a Quote

Types: Glass plate optical sorting machine

Suited for: Nuts, rivets, washers, bushing, elastic rings

Inspecting products

Inspection Screen

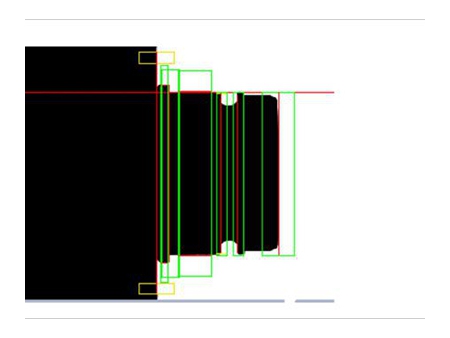

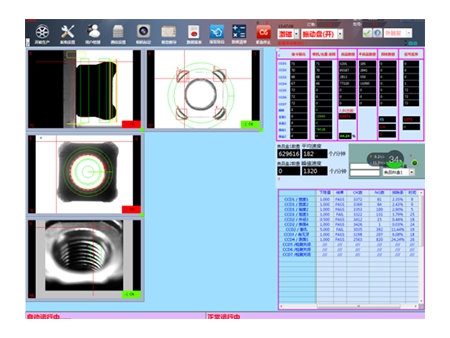

This inspection equipment is outfitted with four industrial CCD cameras. The CCD1 is a head-up camera used for inspecting the multi-segment height and outer diameter of the product. The CCD2 is a vertical bottom view camera used for inspecting the aperture and the burr of the product. The CCD3 is a vertical top view camera used for inspecting the opposite diagonal and angle of the product. It is also used to detect for chamfering. The CCD4 is a 45° tilt camera used to determine if the product has internal threads.

CCD1, head-up

CCD1, head-up  CCD2, vertical bottom view

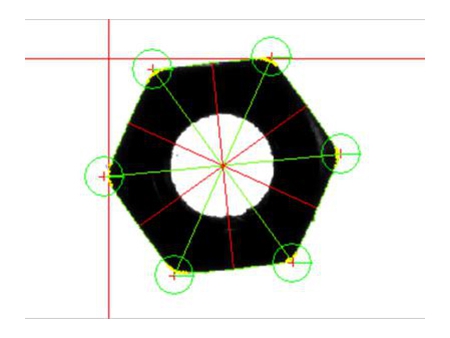

CCD2, vertical bottom view  CCD3, vertical top view

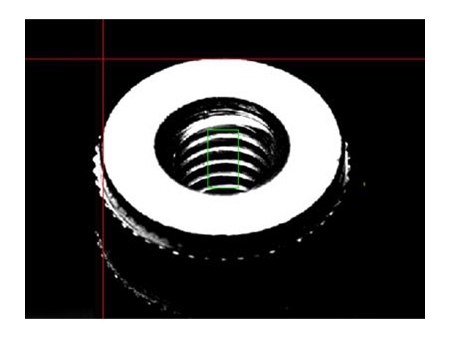

CCD3, vertical top view  CCD4 45°tilt view

CCD4 45°tilt view

Technology parameters:

| Model | RK-1500 |

| Head Outer Diameter (mm) | 1-25 |

| Head Thickness (mm) | 1-15 |

| Total Height(mm) | 1-25 |

| Inspection Accuracy | ±0.01mm |

| Air Pressure (Kg/cm²) | 5 |

| Host Computer | Industrial PC |

| Digital Camera | Industrial CCD |

| Net Weight (KGS) | 650 |

| Dimension(mm) | 1350*1100*1800(LWH) |

Features

- Due to the high transparency of glass, this machine can inspect all products which can be placed stably on the glass platform.

- 2 to 6 additional CCD cameras can be installed according to the inspection parameters on your checklist.

- The inspection and sorting speed depends on the feeding system, up to 500-1200 pieces per minute.

- An automatic counting and packing machine and automatic feeder can be added according to your requirements.

- Changing parts is quick and the equipment is easy to operate.

- Powerful Inspection software

Utilizing the main interface of the inspection software, you can view various data including the inspection speed, conformity rate, total amount of raw material, the rates of exclusion for each inspection item, etc.

- Separate outlet for OK or NG products

This machine has separate OK, NG, and inspection outlets.

The drawer-type inspection outlet is also found on the inspection platform.

The number and position of the outlet can be customized according to your requirements.

- Special track

The machine can be equipped with a special track or general track according to your requirements to ensure the products are orderly distributed on the glass platform.

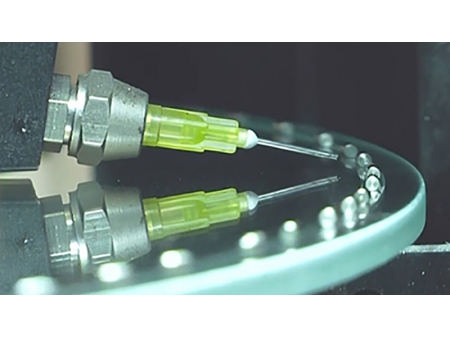

- Solenoid operated blow-off

This machine features a solenoid operated blow-off function that is contactless and operates at high-speed and protects the products from damage.

The compressed air is processed by the dryer equipped with extremely fine micro filters.

Optional accessories

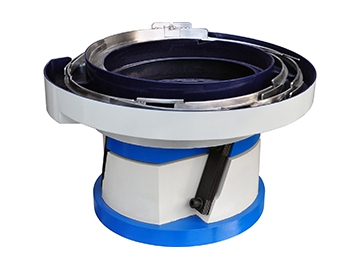

- Vibration bowl

- Feeding elevator

- Automated conveyor system

Related products

Send Message

Most Recent

More

Other Products

Videos