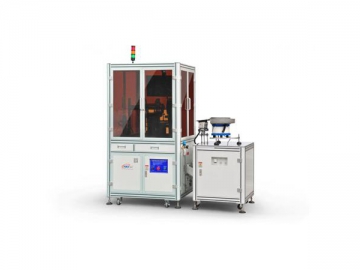

Automatic O-ring Optical Sorting Machine

Request a Quote

Types: Glass plate optical sorting machine

Suited for: O-rings, rubber products and similar parts

Inspecting products

Inspection Screen

This inspection machine comes equipped with two high-precision industrial CCD cameras. The CCD1 is a head-up camera used for inspecting the thickness of products. The CCD2 is a vertical top view camera used for inspecting the inner diameter, outer diameter, and other parameters of each product. The CCD3 is a vertical top view camera used for inspecting for any appearance defects such as burrs and missing material.

Fracture

Fracture Burr

Burr Perforation

Perforation

Technology parameters:

| Model | RK-1500 |

| Head Outer Diameter (mm) | 1-25 |

| Head Thickness (mm) | 1-15 |

| Total Height (mm) | 1-25 |

| Inspection Accuracy | ±0.01mm |

| Air Pressure (Kg/cm²) | 5 |

| Host Computer | Industrial PC |

| Digital Camera | Industrial CCD |

| Net Weight (KGS) | 650 |

| Dimension (mm) | 1350*1100*1800(LWH) |

Features

- Due to the high transparency of glass, this machine can inspect all the products which can be placed stably on the glass platform.

- 2 to 6 additional CCD cameras can be installed according to the inspection parameters on your checklist.

- The inspection and sorting speed depends on the feeding system, up to 500-1200 pieces per minute.

- An automatic counting and packing machine and automatic feeder can be added according to your requirements.

- Parts can be quickly and easily changed.

- Strong versatility

This machine can inspect various products. You only need to change the vibration plate or track.

The preparatory work for inspecting a different type of product only requires about 30 minutes depending on the skill level of the operator.

- Inspection software supports multiple languages

Inspection software supports multiple languages, including Chinese, English, Japanese (Some functions still use Chinese language).

- Conveyor belt blanking

Due to some products that are difficult to move and easily stick to surfaces, a standard outlet may not be suitable for the blanking of the products. This machine uses a conveyor belt to transfer the products to ensure effective blanking.

Optional accessories

Vibration bowl

Vibration bowl Feeding elevator

Feeding elevator Automated conveyor system

Automated conveyor system

Related products

Send Message

Most Recent

More

Other Products

Videos