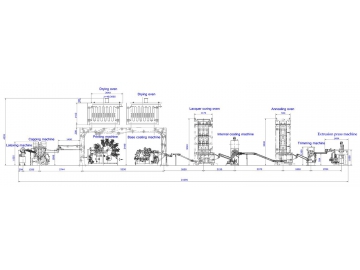

Electrical Lacquer Curing Oven for Aluminum Tube

Application of Equipment and Operating Principle

This machine is the associated equipment of tube machine line, which plays the role of solidification after spraying the inner wall. This curing oven is a necessary equipment in the aluminum tube production line, which equipped with interior wall painting equipment. With a separate drive motor, this curing oven can either run synchronously with the front and rear equipment or work separately.

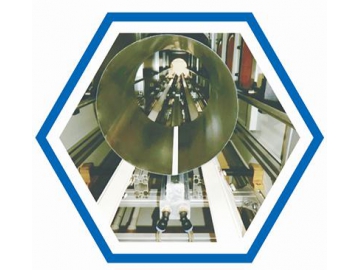

The GHG01 curing oven is heated with gas. The spraying tube, which is driven by the conveyor chain, is transferred to the stainless steel "C" type ship in the curing oven. The "C" type ship pours out the tube after baking at high temperature and falls into the delivering chain. After baking at high temperature for a certain period in the curing oven, the inner spraying liquid attached to the tubes inner wall was dried and firmly attached to the wall, thus completing the whole curing process.

Main technology parameter- Suitable diameter: 16-25mm25-35mm

- Suitable length: 180mm

- Production capacity: 120 tubes/minute

- Electric heating power: 45KW

- Operating temperature: 200-350

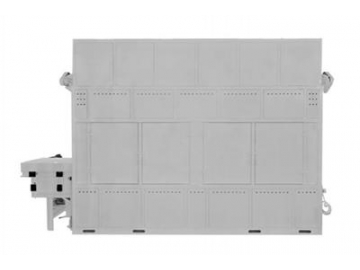

- Dimension: 5022(length)×1400(wide)×2550(height)mm

- Weight of whole machine: 4500Kg

- All electric heating elements in the oven are made of stainless steel thermistor. So the heating is even and the machine is easy to control. The heating element is easy to assemble and disassemble, easy to replace.

- The hot air is continuously circulated in the chamber of oven after loop transportation and the temperature in the heating oven is even, so the annealing effect is good and the product quality is high. The FUJI temperature controller ensures temperature within the plus or minus 2 of set temperature.

- The feed conveying chain adopts continuously variable regulation, which can make the equipment synchronized with the production speed of the front-end equipment. The main driving force of the chain in the oven is provided by the spraying machine.

- The suspended structure of the chamber of oven facilitates maintenance and makes the operation of the conveyor ship more balanced. It reduces the phenomenon of cans being dropped and broken, thus improving the qualification rate of the product.

- Equipped with a separate drive motor, this curing oven can either run synchronously with the front and rear equipment or work separately.