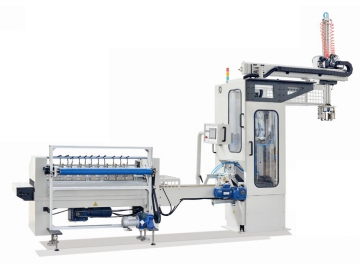

Induction Curing system for powders and lacquers

Request a Quote

The induction curing oven uses SPWM technology to generate vortex heating via an alternating current in order to cure the weld seam coating. The heating length of a single oven is 1.3m with the lowest power consumption at 1kW. This induction curing oven is widely used in can production lines in a variety of specifications and can types, including beverage cans, aerosol cans, milk powder cans, chemical storage cans and more.

Curing

Features

- The induction coil in the induction curing oven is made of a rare earth magnetic material to ensure both the long-term stability and curing effect.

- It uses a bilateral SPWM pulse to suppress the zero-cross point oscillation to ensure the control circuit won’t be affected by the general power supply.

- This oven features an energy saving performance, meaning it will not heat if there is no can detected.

- It features a human to machine interface, PLC system, and digital control.

- This induction curing oven is equipped with a strong exhaust gas discharge device to prevent workshop pollution.

- A variety of can body conveyance methods are available to choose from according to customer requirements.

- An intelligent temperature control function is optional.

Related products

Send Message

Most Recent

More

Other Products

Videos