Continuous Melt Filter with Two Parallel Configured Screen Discs in Plastic Recycling Line

The New Generation of Screen Changer, Ultra-fine Micro Perforation in Melt Filtration

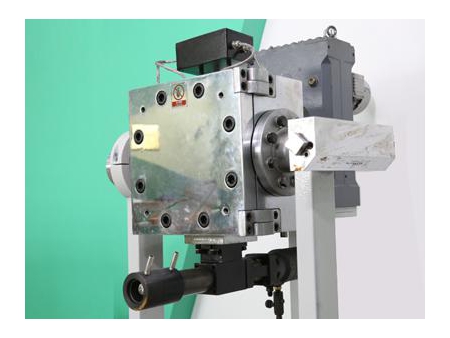

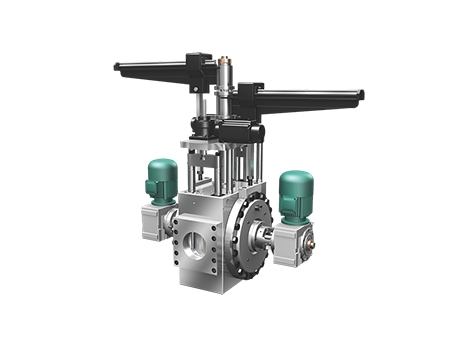

We design and manufacture high quality continuous melt filters for twin or single screw extruders in the plastic recycling industry. The melt-filtration system is suitable for processing recycled polypropylene (PP), polyethylene (PE). polyethylene terephthalate (PET) and polylactic acid (PLA). This is a backflush melt filter with two parallel configured screen discs that is designed for higher contamination content operations. Wood and paper are very common impurities in plastic recycling. Conventional filter systems using mesh screens are usually unable to cope with even small amounts of such impurities. The continuous LN melt filter effectively separates contaminants such as paper, wood, aluminum, or rubber. A scraper removes the contamination from the surface of a rotating screen disc. The LN melt filter has two parallel screen discs, with a maximum throughput of 1200kg per hour.

| Items | Mesh Diameter | Mesh Size | Suitable Extruder | Suitable Plastic | Output Per Hour | Motor Power |

| LN300 | Φ300mm | 5,10,20,30,40,50,60 | Φ150-Φ160 | PP,PE,ABS,PS,PA | 240KG-480KG | 0.75KW |

| LN350 | Φ350mm | 5,10,20,30,40,50,60 | Φ170-Φ180 | PP,PE,ABS,PS,PA | 400KG-640KG | 1.1KW |

| LN400 | Φ400mm | 5,10,20,30,40,50,60 | Φ190-Φ200 | PP,PE,ABS,PS,PA | 560KG-800KG | 1.5KW |

| LN500 | Φ500mm | 5,10,20,30,40,50,60 | Φ250-Φ280 | PP,PE,ABS,PS,PA | 800KG-1200KG | 5.5KW |

- Blade: Germany quality H13, welded by hard alloy, 90° HRC, high wear-resistance.

- Filter body: die steel P20, high strength, high temperature resistance, damage resistant, simple to repair and maintain.

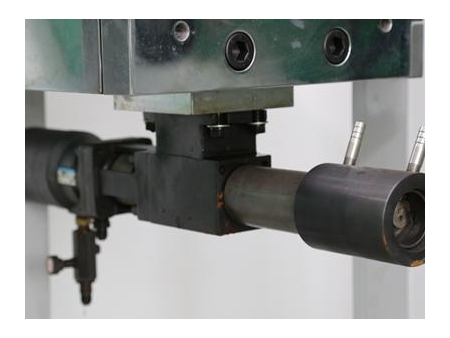

- Mesh screen: tool steel through heat treatment to achieve 65° HRC, longer working life.

- Motor: Siemens.

- Gear box: with hard gear surface and grinding gear, high strength and barely any noise.

- Electric control cabinet: standard equipped with the electric cabinet from Chint Group, featuring high stability. Other brands can also be appointed by customers.

- Hydraulic power unit: four brands are available, including Taiwan Electronic Component, Nojima, Beijing Huaze and Shanghai Lixin.

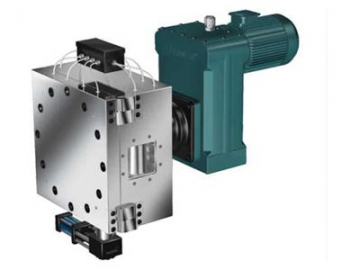

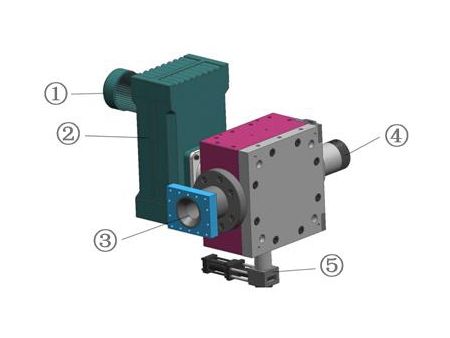

- ①driving motor

- ②reduction gearbox

- ③feeding inlet (connected to the outlet of the granulator)

- ④venting outlet (connected to the mould or the inlet of the granulator)

- ⑤automatic waste discharge device (waste residues are automatically removed from it)

The duplex cleaning blade continuous melt filter is suitable for various types of plastics, such as PP, PE, soft PVC, PS, ABS, PA, etc. The die head of the melt filter can be replaced according to the actual plastic customers need to filter, required output per hour and the mesh size, so that different users’ requirements can be satisfied.

Features- Compared to traditional filter screen, this filter doesn’t require constant replacement of the mesh screen as it allows for a continuous, 24-hour filtration, which makes it a high-performance filter system and an automatic self-cleaning screen.

- Duplex rotating blades and high-speed kneading make it easier to discharge waste, and increases the plasticity and reduces the raw material cost.

- The openable cover board of the filter makes it easier and more convenient to clean the inner cavity, plastic residues and surface of the screen and check the congestion or wear conditions of screen and blades.

- Mesh accessories are also available and the customers don’t have to search and buy any from other manufacturers.