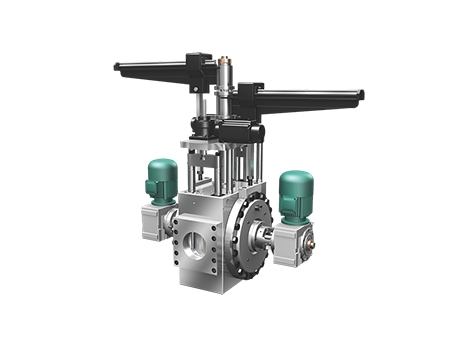

Automatic Filter Changer for Polymer Recycling Line

Request a Quote

The microdrilled continuous melt filter is appropriate for extrusion systems that have higher filtration precision requirements and better raw materials. The microdrilled melt filtration system can produce the most superior finished filtration products. The mesh size varies from 50 to 100.

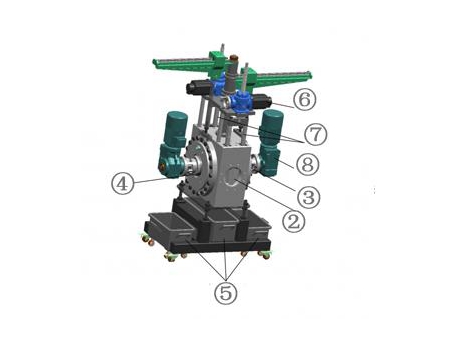

3D model diagram- ①feeding inlet

- ②venting outlet

- ③A working cavity

- ④B working cavity

- ⑤impurity storage bucket

- ⑥driving motor (control the lifting of valve stems)

- ⑦discharge stem (control the opening and closing)

- ⑧blades driving motor

| Items | Mesh Diameter | Suitable Output (kg/h) | Control System | Suitable Plastic | Heating Power | |

| Voltage (V)) | Power (KW) | |||||

| LN300 | Φ250mm | 200-300 | PLC intelligent control | PP, PE, PET, ABS, PS, PA | 220-380 | 15 |

| LN350 | Φ300mm | 300-400 | PLC intelligent control | PP, PE, PET, ABS, PS, PA | 220-380 | 18 |

| LN400 | Φ350mm | 400-500 | PLC intelligent control | PP, PE, PET, ABS, PS, PA | 220-380 | 20 |

| LN500 | Φ400mm | 600-800 | PLC intelligent control | PP, PE, PET, ABS, PS, PA | 220-380 | 30 |

The microdrilled continuous melt filter is suitable for PP, PE, PS, PET, PA and etc.

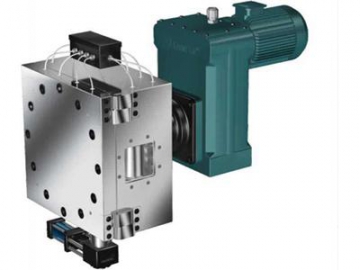

Filter system parts- Blade: inner sigmoid blade, rotating in the opposite direction.

- Filter body: die steel P20, not easily deformed and broken, simple to repair and maintain.

- Mesh screen: tool steel through heat treatment to achieve 65° HRC, longer working life.

- Valve actuator: four feeding and venting valves are controlled by PLC servo motors, which bring higher precision.

- Waste discharge actuating device: F series speed reducer. Blades, equipped on the screws, rotate together and discharge the waste simultaneously. The waste will be cooled by the screws, smokeless and environment friendly.

- PLC control system: Schneider or Siemens contactor, Inovance servo motor, Inovance controller, Siemens or Mitsubishi PLC control system.

- Touch panel: Taiwan’s brand.

- The left and right filtration system of this machine are symmetrically arranged and operate independently. When the left filtering mechanism discharges the waste, the right filtering mechanism can continue to filter and vice versa. That have achieved freely switch operation, PLC control.

- This filter waste discharge time is short, After cooling through screws, the automatically discharged slag is smokeless, which highly improves the automatic slagging performance and filtration efficiency.

- The hydraulic motor of this machine can drive the screw slagging device and the blade, and combine the two structures into one.

- The lifting cylinder of the invention simultaneously drives the feeding valve stem and the discharging valve stem to seal the feeding inlet and the discharging opening. When the two valve stems are moving, the total amount of the feeding is always equal to the total amount of the discharging, thereby realizing there is no fluctuation when the rod moves.

- The high press gas inside the filtration cavity travels through the exhaust passage to the outside. Starting the blades after decompression prevents the mesh from breaking and extends its working life.

- The mesh is hanged on the sliding rail, which brings more convenience for destuffing. Fewer replacements of the mesh, will reduce the expensive usage cost, increase the profit and improve the market competitiveness.

Related products

Send Message

Most Recent

More

Other Products

Videos