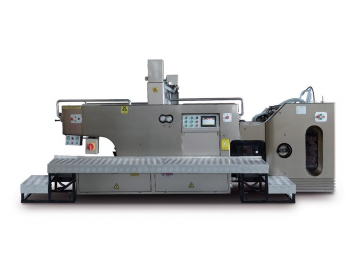

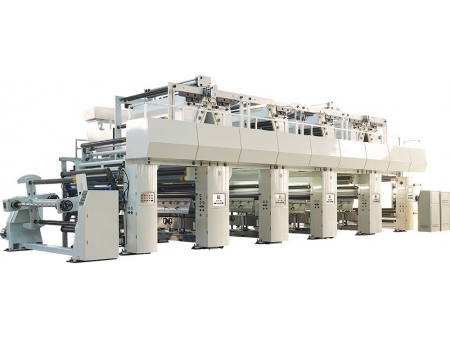

TC-72 Automatic Stop Cylinder Screen Printing Press

Recommended application

The TC-72 automatic stop cylinder screen printing press is mainly used for industrial printing operations. It is especially suitable for highly precise thin film printing of various products such as electrical products, electronic products, domestic appliances and automobiles. Suitable printing materials include PET, PVC, PC, transfer paper, label paper, IMD, MEM-BRANE, electronic switches, instrument panel labels, and other sheet materials.

The TC-72 automatic stop cylinder screen printing press adopts several innovative techniques for the screen printing of sheet material:

1.Pre-suction feeder: this feeder is equipped with an ionized blower and ultra-sonic detection, so that it can solve the problem of sticky materials and scratching.

2.Anti-static electricity material feeder: this feeder adopts vacuum feeding which can solve scratching during delivery and the adjustment is convenient.

3.Stop cylinder roller: it is equipped with a front stop cylinder and side guide optic fiber positioning to ensure precise positioning.

4.By adopting a pneumatic scraper system: it can simplify the main structure of the press. And the operation is made convenient, while the maintenance and printing cost is low.

The listed promotion can ensure that the printing press can realize perfect screen printing on sheet materials of which the thickness is from 0.05-0.8mm. The printing accuracy can be up to 0.03mm. And there will be over 10 times the precision of color registration.

| Model | TC-72 |

| Maximum material size(mm) | 520×720 |

| Minimum material size(mm) | 250×300 |

| Frame size(mm) | 900×920 |

| Printing speed(Pcs/h) | 400 - 2400 |

| Power Specifications | 3P 380V 50Hz 7 Kw |

| Gas specifications | 225I/min 5-7Kgs/ |

| Weight(Kg) | 3550 |

| Dimensions(mm) | 3250×2550×2080 |

Details

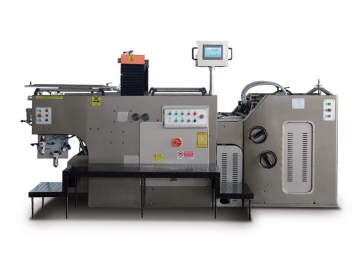

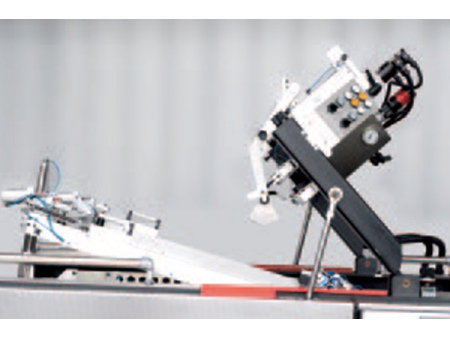

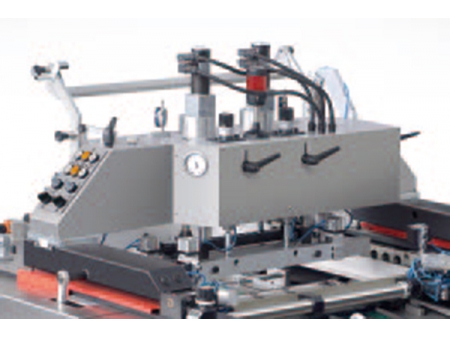

The TC-72 automatic stop cylinder screen printing press is outfitted with an open type oblique screen lifting system. The beam of the rubber scraper is installed on the installation and debugging station with a bevel angle to the printing station. Therefore, the replacement and cleaning of the rubber scraper is convenient. It is also easy to add ink and clean screen printing plates. The supporting frame of the screen plates can also be pulled out with the bevel angle to realize easy cleaning. Re-positioning is not required after this motion.

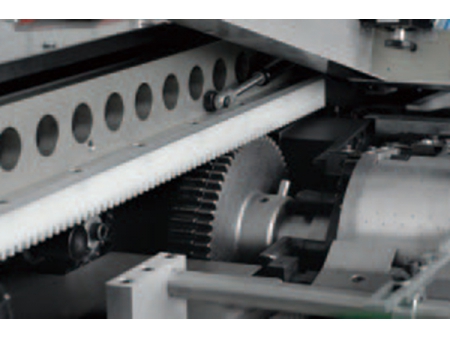

The synchronous movement of the screen printing plate and roller is driven by a durable nylon rack and steel gear. The gear guarantees that there will be no motion error or retrace error between gears and racks as the components are precision machined. Therefore, there will be low abrasion, extending the service life of the machine.

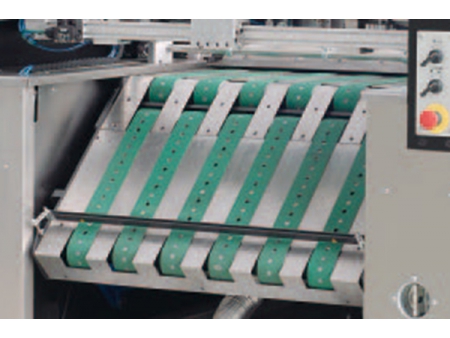

Material discharging system: this system can ensure traceless material transportation from printing operations to subsequent drying processes. Down folding device: this device can realize easy plate cleaning, rubber scraper and ink collection, scraper installation and disassembly.

The TC-72 automatic stop cylinder screen printing press adopts a heavy and highly precise scraper system of which the descending pressure of the scraper can be pre-set. The position of the scraper can be controlled, and the pressure of the rubber scraper will be constant immediately after calibration so the thickness of the ink layer can be precisely controlled. As a result, we can achieve perfect and uniform presswork.

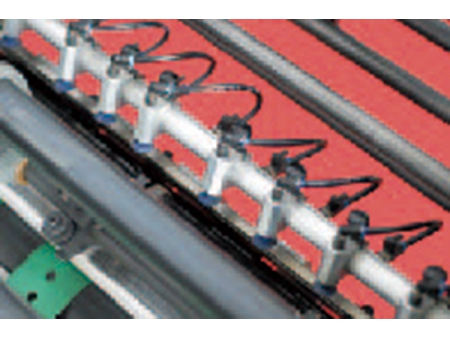

The front suction feeder is equipped with a wind suction system at the front end, so that there will be no scratching on the surface of the sensitive printing target during material feeding. This device is suitable for printing of thin paper, film and some other printing materials that can generate static electricity and are easily scratched. Even for multi-color printing jobs, the surface of the printing target will not be scratched.

This printing press is equipped with a photoelectric anti-overlapping system which can monitor the material without attachment, so that the printing target will not be scratched.

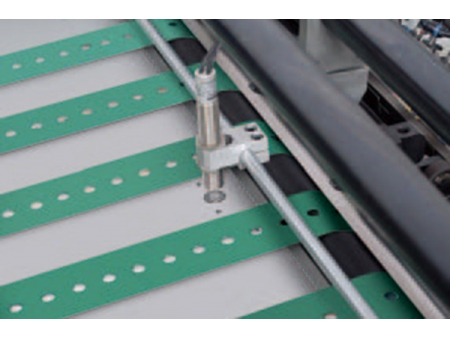

The press adopts vacuum side guide system which is supported by side guide optic fiber positioning to ensure precise and reliable side guide positioning. Meanwhile, the trace of side guide pulling and positioning can be effectively prevented.

This press has unique roller grooves, so that the distance between screens can be adjusted near 0. This can realize ultra-small screen deformation, ensuring the precision of printing figures.