Hot Forming Process

Hot forming by mandrel is suitable for production of seamless steel pipe fittings. The process consists of hot forming press and middle frequency induction mandrel. We are able to produce large size elbows with steel pipes with small diameters through this exact process. For example, if the diameter of raw steel pipe is 6 inches, then we could manufacture elbows with diameter of 10 inches and even 12 inches.

Since steel pipes used during this kind of production process are usually seamless, no further welding will be required. The subsequent procedure after the process will be similar with that of cold press forming process.

- Steel pipe feeding

- Cutting

- Hot press forming

- Non-destructive testing

- Heat treatment

- Calibration

- Metal processing

- Pickling and passivation

- Surface treatment

- Inspection

- Identification

- Shipping

We have three sets of elbow cold press forming machines, which feature high automation degree, thereby being able to produce seamless pipe fittings with caliber ranging from 0.5 inches and 20 inches in quantity.

| Name | Qty. | Available elbow size | Maximum wall thickness |

| Hot press forming machine | 1 | 1-8 inches | Sch XXS |

| Hot press forming machine | 1 | 10-24 inches | Sch XXS |

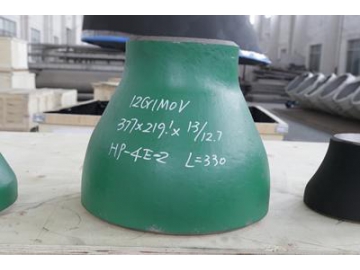

Carbon steel elbow:ASTM A234 WPB, WPC,Q235B,16Mn/ Q345B, etc.

Low temperature steel elbow:ASTM A420 WPL3, WPL6, WPL8, WPL9, etc.

Alloy steel elbow:ASTM A234 WP11, WP22, WP5, WP9, WP91, etc.

Steel elbow for pipeline:ASTM A860 (MSS SP-75) WPHY42, WPHY52, WPHY60, WPHY65, WPHY70, WPHY80, etc.

The titanium elbows, copper elbows and non ferrous metal products are also available.