Alloy Steel Tee Pipe Fittings (Equal Tee, Reducing Tee)

Alloy steel tee pipe fittings are usually applied to connect three lengths of pipes to redirect the fluid flow direction. More specifically, they are used for distributing or collecting the fluid from the run pipe. Our company provides both equal tees and reducer tees, which are all available with various shapes and diameters, thus being able to fulfill different requirements from customers.

Common alloy steel features great tenacity, thermal conductivity and electrical conductivity. It could also be a kind of carbon steel which is alloyed with other alloying elements, such as silicon, manganese, chromium, nickel, tungsten, vanadium and titanium, to improve its mechanical properties, including abrasion resistance, corrosion resistance and low temperature resistance, etc. The properties will vary depending on the alloying element types and percentages. Another kind of alloy steel, low temperature service steel, is specifically used for production of pipe fittings applied in circumstances with temperature ranging between -20 and -253℃.

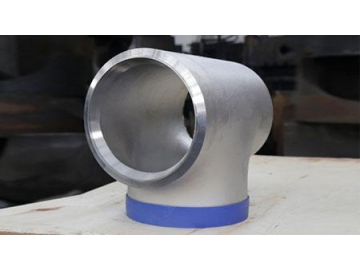

Sample Exhibition Hot forming alloy steel Seamless Tee

Hot forming alloy steel Seamless Tee

Cold forming by mold or hot forming by mold is the most primarily applied process for manufacturing of alloy steel tee pipe fittings. Through this process, our company is fully capable of producing alloy steel tee with different diameters with seamless steel pipes.

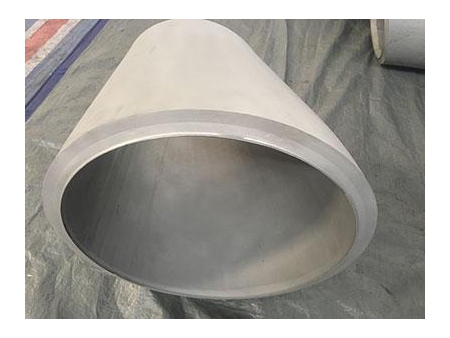

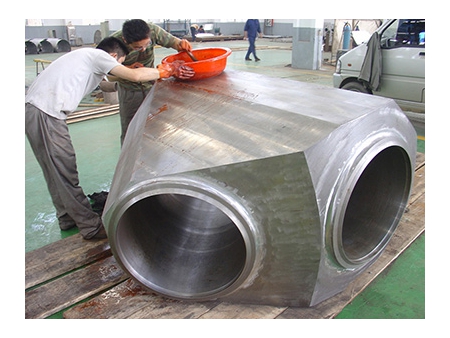

Hot Forming Alloy Steel Welded Tees

Hot Forming Alloy Steel Welded Tees

If required, we are also be able to produce alloy steel tee with large diameter, for example, 100 inch(DN2500), by placing steel plate into corresponding mould and conducting compression-molding process.

An extensive use of alloy steel fittings can be found in the following industries:

- Petrochemical industry: Oil refining, ethylene, coal to oil, coal to olefins and other projects.

- Natural gas industry: LNG ships, LNG terminals, and natural gas pipeline projects.

- Power station industry: In thermal power plant, the water pipeline used for supercritical units, circulating fluidized beds, power generation boilers, steam turbines, generators and other equipment.

- Marine engineering industry: Construction and maintenance projects for offshore platform engineering

- Shipbuilding industry: Ship maintenance project

- Others: papermaking, machinery manufacturing and other industries.

| Parameters | DN15-DN2500 (1/2"-100") |

| Wall thickness | Conventional wall thickness range: Sch 5s to Sch XXS Maximum wall thickness: 120mm |

| Standard | ASME B16.9, DIN2615, JIS B2312, JIS B2313, DIN2615, DIN EN10253, GB/T12459, GB/T13401, SH3408, SH3409,GOST17376, MSS-SP-75, and etc. |