Resin Bond Diamond/CBN Grinding Wheel

Request a Quote

At Yubao, we design and manufacture precision resin bond diamond and CBN wheels to meet or exceed your grinding applications.

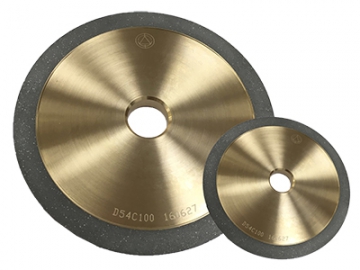

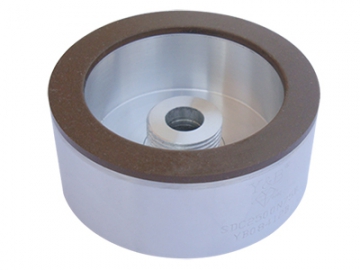

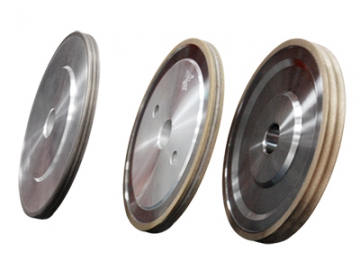

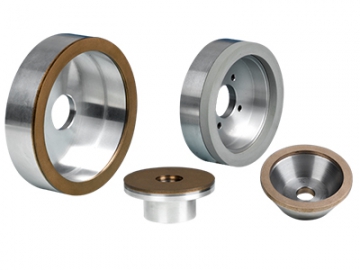

Followings are our standard type of resin bond diamond & CBN grinding wheels.

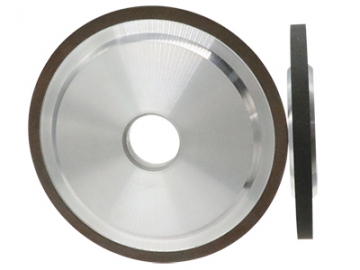

Ideal for grinding PCB drill bits, and is available in both a straight type and flaring cup type.

| Outer diameter (mm) | Overall thickness (mm) | Arbor hole diameter (mm) | Abrasive width (mm) | Abrasive thickness (mm) | |

| 40 | 10-20 | 10 | 3/5 | 2/3/4 | |

| 50 | 10-20 | 10 | 3/5/6/8 | 2/3/4/5 | |

| 75 | 10-25 | 10/19.05/20 | 3/5/6/8/10 | 3/4/5/6 | |

| 100 | 15-30 | 19.05/20 | 3/5/6/8/10/12/15/20 | 3/4/5/6 | |

| 125/150 | 15-35 | 25.4/31.75/32 | 3/5/6/8/10/12/15/20/25/30 | 3/4/5/6 | |

| 175 | 15-40 | 25.4/31.75/32 | 5/6/8/10/12/15/20/25 | 3/4/5/6/8 | |

| 200 | 20-55 | 25.4/31.75/32 | 6/8/10/12/15/20/25 | 3/4/5/6/8 | |

| 250 | 20-55 | 32/75 | 5/6/8/10/12/15/20/25/30 | 3/4/5/6/8 | |

| 300 | 25-60 | 75/127 | 10/12/15/20/25/30 | 4/5/6/8/10 | |

| 350 | 30-60 | 75/127 | 10/12/15/20/25/30 | 4/5/6/8/10 | |

| 400 | 30-60 | 127/203 | 15/20/25/30/35/40 | 4/5/6/8/10 | |

| 450 | 30-80 | 127/203 | 20/25/30/35/40/50 | 4/5/6/8/10 |

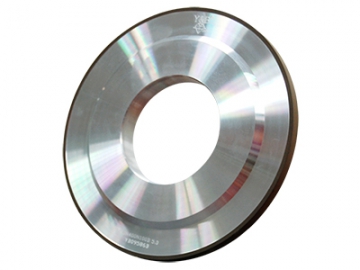

Ideal for grinding semiconductors, such as light guide plates, electronic circuits, light guide glass, fibers and more.

| Outer diameter (mm) | Overall thickness (mm) | Arbor hole diameter (mm) | Wheel core dimension (mm) | Abrasive thickness (mm) | Abrasive width (mm) | |

| 75 | 5-10 | 19.05/20 | 40-50 | 0.8-5 | 2-5 | |

| 100 | 5-15 | 19.05/20/31.75/32 | 50-80 | 1-8 | 3-6 | |

| 125 | 5-15 | 19.05/20/31.75/32 | 90-110 | 1-8 | 3-6 | |

| 150 | 10-15 | 31.75/32 | 100-130 | 1-10 | 3-6 | |

| 175 | 12-20 | 31.75/32 | 120-140 | 1-10 | 3-6 | |

| 200 | 12-30 | 31.75/32/75 | 130-160 | 2-10 | 4/5/6/8/10 | |

| 250 | 12-30 | 31.75/32/75 | 150-200 | 5-10 | 4/5/6/8/10 | |

| 300 | 15-40 | 127/203 | 200-250 | 6-15 | 4/5/6/8/10 | |

| 350 | 15-40 | 127/203 | 250-300 | 6-15 | 4/5/6/8/10 | |

| 400 | 20-50 | 127/203 | 300-350 | 6-20 | 5/6/8/10/12/15 | |

| 500 | 20-50 | 203/305 | 350-400 | 10-30 | 5/6/8/10/12/15 | |

| 600 | 20-60 | 305 | 400-500 | 10-30 | 5/6/8/10/12/15 | |

| 700 | 20-60 | 305 | 450-600 | 10-30 | 5/6/8/10/12/15 |

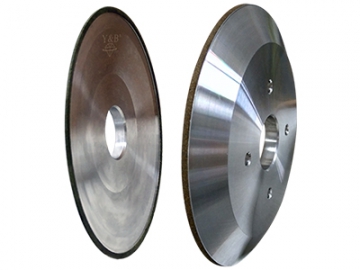

Ideal for grinding paper cutting tools and other blades.

| Outer diameter (mm) | Overall thickness (mm) | Arbor hole diameter (mm) | Abrasive width (mm) | Abrasive thickness (mm) | |

| 40 | 10-20 | 10 | 3/5 | 2-4 | |

| 50 | 10-25 | 10 | 3/5/6/8 | 2-5 | |

| 75 | 10-25 | 10/19.05/20 | 3/5/6/8/10 | 2-5 | |

| 100 | 15-30 | 19.05/20 | 3/5/6/8/10/12/15/20 | 3-6 | |

| 125/150 | 15-35 | 25.4/31.75/32 | 3/5/6/8/10/12/15/20/25/30 | 3-6 | |

| 175 | 15-40 | 25.4/31.75/32 | 6/8/10/12/15/20/25 | 3/4/5/6/8 | |

| 200 | 20-55 | 25.4/31.75/32 | 6/8/10/12/15/20/25/30 | 3/4/5/6/8 | |

| 250 | 20-55 | 32/75 | 6/8/10/12/15/20/25/30 | 3/4/5/6/8 | |

| 300 | 25-60 | 75/127 | 10/12/15/20/25/30 | 4/5/6/8/10 | |

| 350 | 30-60 | 75/127 | 10/12/15/20/25/30 | 4/5/6/8/10 | |

| 400 | 30-60 | 127/203 | 15/20/25/30/35/40 | 4/5/6/8/10 | |

| 450 | 30-80 | 127/203 | 20/25/30/35/40/50 | 4/5/6/8/10 |

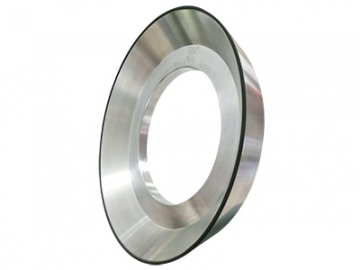

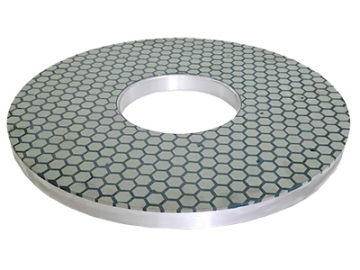

Ideal for polishing light guide plates, LED bulb shells, and other photic and electrical productsinto a mirror finish.

| Outer diameter (mm) | Overall thickness (mm) | Arbor hole diameter (mm) | Wheel core dimension (mm) | Abrasive thickness (mm) | Abrasive width (mm) | |

| 75 | 5-10 | 19.05/*20 | 40-50 | 0.8-5 | 2-5 | |

| 100 | 5-15 | 19.05/20/31.75/32 | 50-80 | 1-8 | 3-6 | |

| 125 | 5-15 | 19.05/20/31.75/32 | 90-110 | 1-8 | 3-6 | |

| 150 | 10-15 | 31.75/32 | 100-130 | 1-10 | 3-6 | |

| 175 | 12-20 | 31.75/32 | 120-140 | 1-10 | 3-6 | |

| 200 | 12-30 | 31.75/32/75 | 130-160 | 2-10 | 4/5/6/8/10 | |

| 250 | 12-30 | 31.75/32/75 | 150-200 | 5-10 | 4/5/6/8/10 | |

| 300 | 15-40 | 127/203 | 200-250 | 6-15 | 4/5/6/8/10 | |

| 350 | 15-40 | 127/203 | 250-300 | 6-15 | 4/5/6/8/10 | |

| 400 | 20-50 | 127/203 | 300-350 | 6-20 | 5/6/8/10/12/15 | |

| 500 | 20-50 | 203/305 | 350-400 | 10-30 | 5/6/8/10/12/15 | |

| 600 | 20-60 | 305 | 400-500 | 10-30 | 5/6/8/10/12/15 | |

| 700 | 20-60 | 305 | 450-600 | 10-30 | 5/6/8/10/12/15 |

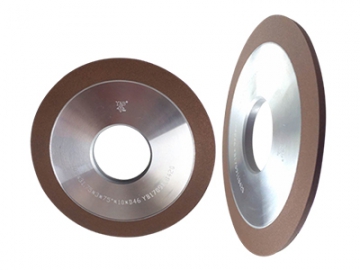

Ideal for rough grinding, fine grinding, and polishing of woodworking tools.

| Outer diameter (mm) | Overall thickness (mm) | Arbor hole diameter (mm) | Arbor hole width (mm) | Abrasive width (mm) | Abrasive thickness (mm) | |

| 75 | 12 | 10/19.05/20 | 5 | 3/5/6/8/10 | 2/3/4/6 | |

| 100 | 15 | 19.05/20 | 6 | 3/5/6/8/10 | 2/3/4/6 | |

| 125 | 18 | 31.75/32 | 8 | 5/6/10 | 2/3/4/6 | |

| 150 | 20 | 31.75/32 | 9 | 5/6/10/15 | 2/3/4/6 | |

| 175 | 22 | 31.75/32 | 10 | 6/10/15 | 2/3/4/6 | |

| 200 | 24 | 31.75/32/40/75 | 11 | 6/10/15/20 | 2/3/4/6 | |

| 250 | 26 | 31.75/32/40/75 | 12 | 6/10/15/20 | 2/3/4/6 |

Ideal for grinding monocrystalline and polycrystalline silicon.

| Outer diameter (mm) | Overall thickness (mm) | Arbor hole diameter (mm) | Abrasive width (mm) | Abrasive thickness (mm) | |

| 75 | 25 | 19.05/20 | 1.5/3 | 6/10 | |

| 100 | 25/30 | 19.05/20 | 1.5/3 | 6/10 | |

| 125 | 25/30 | 31.75/32 | 1.5/3 | 6/10 | |

| 150/175 | 30/35 | 31.75/32 | 1.5/3 | 6/10 | |

| 200/250 | 35/40/50 | 31.75/32/75 | 1.5/3 | 6/10 |

Ideal for grinding alloy hobbing cutters.

| Outer diameter (mm) | Overall thickness (mm) | Arbor hole diameter (mm) | Arbor hole width (mm) | Abrasive width (mm) | Abrasive thickness (mm) | |

| 75 | 25/30/32 | 19.05/20 | 10 | 3/5/6/8/10 | 2-6 | |

| 90 | 25-40 | 19.05/20 | 10 | 3/5/6/8/10 | 2-6 | |

| 100 | 25-40 | 19.05/20/31.75/32 | 10 | 6/8/10/12 | 2-6 | |

| 125/150 | 25-40 | 19.05/20/31.75/32 | 10 | 8/10/12/15 | 3-8 | |

| 200 | 30-50 | 31.75/32/40 | 12/15 | 8/10/12/15/20/25 | 3-8 |

Ideal for grinding Tungsten carbide tools.

| Outer diameter (mm) | Overall thickness (mm) | Arbor hole diameter (mm) | Arbor hole width (mm) | Abrasive width (mm) | Abrasive thickness (mm) | |

| 30 | 15 | 8/10 | Customized | 2-10 | 1.5-10 | |

| 50 | 25 | 10/19.05/20 | Customized | 2-10 | 1.5-10 | |

| 75 | 25/30/32 | 19.05/20 | 10 | 3/5/6/8/10 | 2-6 | |

| 90 | 35/40 | 19.05/20 | 10 | 3/5/6/8/10 | 2-6 | |

| 100 | 25-40 | 19.05/20/31.75/32 | 10 | 6/8/10/12 | 2-6 | |

| 125/150 | 25-40 | 19.05/20/31.75/32 | 10 | 8/10/12/15 | 3-8 | |

| 200 | 30-50 | 31.75/32/40 | 12/15 | 8/10/12/15/20/25 | 3-8 | |

| Note: other specifications can be customized upon request! | ||||||

Ideal for grooving carbide tools.

| Outer diameter (mm) | Overall thickness (mm) | Arbor hole diameter (mm) | Abrasive thickness (mm) | |

| 50/75/100/120/150 | 8/10/12 | 20/31.75/32 | 5-10 |

Ideal for fine grinding and polishing for carbides, cermet, ceramics, lenses and other materials.

| Outer diameter (mm) | Overall thickness (mm) | Arbor hole diameter (mm) | Abrasive width (mm) | Abrasive thickness (mm) | |

| 400/450/500 | 40 | Customized | 40 | 4-5 |

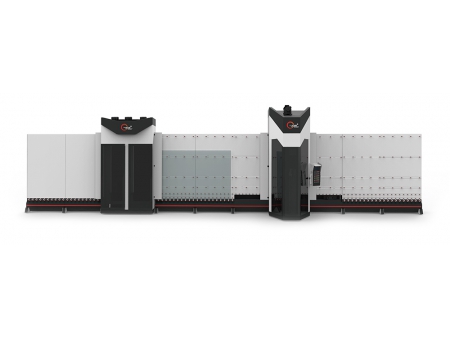

It has a variety of types to match advanced CNC machinery produced by different manufacturers.

| Outer diameter | Overall thickness | Arbor hole diameter | Abrasive width | |

| 12 | 8-12 | 6 | 2/3 | |

| 14/15 | 8-14 | 6 | 2/3 | |

| 16/18/20 | 8-16 | 10 | 2/3 | |

| 23 | 12-20 | 10 | 2/3 | |

| 25 | 2-20 | 5/6/8/10/12 | 2/2.5/3/4 | |

| 30 | 2-20 | 5/6/8/10/12/13 | 2/2.5/3/4 | |

| 35 | 2-20 | 10/12/12.7/16 | 2/2.5/3/4/5 | |

| 40/45/50 | 0.2-20 | 8/10/12/12.7/16 | 2/2.5/3/4/5 | |

| 60 | 0.2-20 | 8/10/12/12.7/16/19.05/20/22.23 | 2/2.5/3/4/5 | |

| 75/80 | 0.4-30 | 10/16/19.05/20/22.23/25.4 | 3/4/5 | |

| 100 | 0.4-35 | 20/22.23/25.4/31.75/32 | 3-6 | |

| 115 | 2-20 | 20/22.23/25.4/31.75/32 | 3-6 | |

| 125 | 0.8-35 | 20/22.23/25.4/31.75/32 | 4/5/6/8/10 | |

| 150 | 1-35 | 25.4/31.75/32/40 | 4/5/6/8/10 | |

| 175 | 3-35 | 31.75/32/40 | 5/6/8/10/16 | |

| 180 | 10-40 | 31.75/32/40/50.8/75/76.2 | 5/6/8/10/16 | |

| 200 | 1-40 | 31.75/32/40/50.8/75/76.2 | 5/6/8/10/16/20 | |

| 250 | 10-60 | 50.8/75/76.2/101.6/127 | 5/6/8/10/16/20 | |

| 300 | 3-60 | 75/76.2/101.6/127/203 | 5/6/8/10/16/20/25 | |

| 350 | 12-50 | 127/203 | 5/6/8/10/16/20/25 | |

| 400 | 3.5-50 | 127/203 | 5/6/8/10/16/20/25 | |

| 450/500/600/700/750 | 12-60 | 203/304.8/305 | 5/6/8/10/12/15 | |

| 800/850/900 | 18-50 | 132/304.8/305 | 5/6/8/10/12/15 |

Ideal for grinding alloy blades, indexable inserts, PCD inserts, PCBN inserts, and more.

| Outer diameter | Overall thickness | Arbor hole diameter | Abrasive thickness | Abrasive width | |

| 300/350/400 | 20-50 | 207/225/325/350 | 4/6/8/10/12 | 3-10 |

Ideal for grinding carbide milling tools.

| Outer diameter (mm) | Overall thickness (mm) | Arbor hole diameter (mm) | Wheel core dimension (mm) | Abrasive thickness (mm) | Abrasive width (mm) | |

| 75 | 5-10 | 19.05,20 | 40-50 | 0.8-5 | 2-5 | |

| 100 | 5-15 | 19.05/20/31.75/32 | 50-80 | 1-8 | 3-6 | |

| 125 | 5-15 | 19.05/20/31.75/32 | 90-110 | 1-8 | 3-6 | |

| 150 | 10-15 | 31.75/32 | 100-130 | 1-10 | 3-6 | |

| 175 | 12-20 | 31.75/32 | 120-140 | 1-10 | 3-6 | |

| 200 | 12-30 | 31.75/32/75 | 130-160 | 2-10 | 4/5/6/8/10 | |

| 250 | 12-30 | 31.75/32/75 | 150-200 | 5-10 | 4/5/6/8/10 | |

| 300 | 15-40 | 127/203 | 200-250 | 6-15 | 4/5/6/8/10 | |

| 350 | 15-40 | 127/203 | 250-300 | 6-15 | 4/5/6/8/10 | |

| 400 | 20-50 | 127/203 | 300-350 | 6-20 | 5/6/8/10/12/15 | |

| 500 | 20-50 | 203/305 | 350-400 | 10-30 | 5/6/8/10/12/15 | |

| 600 | 20-60 | 305 | 400-500 | 10-30 | 5/6/8/10/12/15 | |

| 700 | 20-60 | 305 | 450-600 | 10-30 | 5/6/8/10/12/15 |

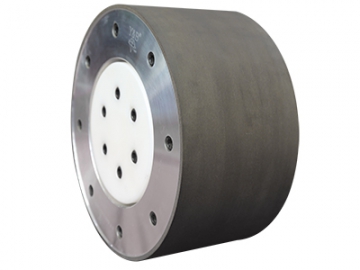

Ideal for grinding Tungsten rods, ceramic rods and rods made of other materials.

| Outer diameter (mm) | Overall thickness (mm) | Arbor hole diameter (mm) | Abrasive thickness (mm) | |

| 300 | 100/150 | 120.03 | 6/10 | |

| 350 | 125 | 127 | 6/10 | |

| 400 | 150 | 203 | 5 | |

| 450 | 205/255 | 228.6 | 6 |

Ideal for grinding alloy blades, including milling cutters, drill bits, spade bits, step reamers, gravers, and more.

| Outer diameter (mm) | Overall thickness (mm) | Arbor hole diameter (mm) | Abrasive width (mm) | |

| 12 | 8-12 | 6 | 2/3 | |

| 14 | 8-14 | 6 | 2/3 | |

| 15 | 8-14 | 6 | 2/3 | |

| 16/18/20 | 8-16 | 10 | 2/3 | |

| 23 | 12-20 | 10 | 2/3 | |

| 25 | 2-20 | 5/6/8/10/12 | 2/2.5/3/4 | |

| 30 | 2-20 | 5/6/8/10/12/13 | 2/2.5/3/4 | |

| 35 | 2-20 | 10/12/12.7/16 | 2/2.5/3/4/5 | |

| 40/45/50 | 0.2-20 | 8/10/12/12.7/16 | 2/2.5/3/4/5 | |

| 60 | 0.2-20 | 8/10/12/12.7/16/19.05/20/22.23 | 2/2.5/3/4/5 | |

| 75/80 | 0.4-30 | 10/16/19.05/20/22.23/25.4 | 3/4/5 |

Ideal for grinding carbide tools, cermet cutters and other blade tools.

| Outer diameter (mm) | Overall thickness (mm) | Arbor hole diameter (mm) | Abrasive width (mm) | Abrasive thickness (mm) | |

| 40 | 10-20 | 10 | 3/5 | 2-4 | |

| 50 | 10-25 | 10 | 3/5/6/8 | 2-5 | |

| 75 | 10-25 | 10/19.05/20 | 3/5/6/8/10 | 2-5 | |

| 100 | 15-30 | 19.05/20 | 3/5/6/8/10/12/15/20 | 3-6 | |

| 125 | 15-35 | 25.4/31.75/32 | 3/5/6/8/10/12/15/20/25/30 | 3-6 | |

| 150 | 15-35 | 25.4/31.75/32 | 3/5/6/8/10/12/15/20/25/30 | 3-6 | |

| 175 | 15-40 | 25.4/31.75/32 | 6/8/10/12/15/20/25 | 3/4/5/6/8 | |

| 200 | 20-55 | 25.4/31.75/32 | 6/8/10/12/15/20/25/30 | 3/4/5/6/8 | |

| 250 | 20-55 | 32/75 | 6/8/10/12/15/20/25/30 | 3/4/5/6/8 | |

| 300 | 25-60 | 75/127 | 10/12/15/20/25/30 | 4/5/6/8/10 | |

| 350 | 30-60 | 75/127 | 10/12/15/20/25/30 | 4/5/6/8/10 | |

| 400 | 30-60 | 127/203 | 15/20/25/30/35/40 | 4/5/6/8/10 | |

| 450 | 30-80 | 127/203 | 20/25/30/35/40/50 | 4/5/6/8/10 |

Ideal for grinding cutters, carbide saw blade, and grooving thread taps.

| Outer diameter (mm) | Overall thickness (mm) | Arbor hole diameter (mm) | Wheel core dimension (mm) | Abrasive thickness (mm) | Abrasive width (mm) | |

| 75 | 5-10 | 19.05/20 | 40-50 | 1-5 | 3/4/5 | |

| 100 | 5-15 | 19.05/20/31.75/32 | 50-80 | 1-8 | 3-6 | |

| 125 | 5-15 | 19.05/20/31.75/32 | 90-110 | 1-8 | 3-6 | |

| 150 | 10-15 | 31.75/32 | 100-130 | 2-10 | 3-6 | |

| 175 | 12-20 | 31.75/32 | 120-140 | 2-10 | 3-6 | |

| 200 | 12-30 | 31.75/32/75 | 130-160 | 2-10 | 4/5/6/8/10 | |

| 250 | 12-30 | 31.75/32/75 | 150-200 | 5-10 | 4/5/6/8/10 | |

| 300 | 15-40 | 127/203 | 200-250 | 6-15 | 4/5/6/8/10 | |

| 350 | 15-40 | 127/203 | 250-300 | 6-15 | 4/5/6/8/10 | |

| 400 | 20-50 | 127/203 | 300-350 | 6-20 | 5/6/7/8/10/12/15 |

Ideal for grinding alloy blades, including milling cutters, drill bits, spade bits, step reamers, gravers, and more.

| Outer diameter (mm) | Overall thickness (mm) | Arbor hole diameter (mm) | Abrasive width (mm) | |

| 12 | 8-12 | 6 | 2/3 | |

| 14/15 | 8-14 | 6 | 2/3 | |

| 16/18/20 | 8-16 | 10 | 2/3 | |

| 23 | 12-20 | 10 | 2/3 | |

| 25 | 2-20 | 5/6/8/10/12 | 2/2.5/3/4 | |

| 30 | 2-20 | 5/6/8/10/12/13 | 2/2.5/3/4 | |

| 35 | 2-20 | 10/12/12.7/16 | 2/2.5/3/4/5 | |

| 40/45/50 | 0.2-20 | 8/10/12/12.7/16 | 2/2.5/3/4/5 | |

| 60 | 0.2-20 | 8/10/12/12.7/16/19.05/20/22.23 | 2/2.5/3/4/5 | |

| 75 | 0.4-30 | 10/16/19.05/20/22.23/25.4 | 3/4/5 | |

| 80 | 0.4-30 | 10/16/19.05/20/22.23/25.4 | 3/4/5 | |

| 100 | 0.4-35 | 20/22.23/25.4/31.75/32 | 3-6 | |

| 115 | 2-20 | 20/22.23/25.4/31.75/32 | 3-6 | |

| 125 | 0.8-35 | 20/22.23/25.4/31.75/32 | 4/5/6/8/10 | |

| 150 | 1-35 | 25.4/31.75/32/40 | 4/5/6/8/10 | |

| 175 | 3-35 | 31.75/32/40 | 5/6/8/10/16 | |

| 180 | 10-40 | 31.75/32/40/50.8/75/76.2 | 5/6/8/10/16 | |

| 200 | 1-40 | 31.75/32/40/50.8/75/76.2 | 5/6/8/10/16/20 | |

| 250 | 10-60 | 50.8/75/76.2/101.6/127 | 5/6/8/10/16/20 | |

| 300 | 3-60 | 75/76.2/101.6/127/203 | 5/6/8/10/16/20/25 | |

| 350 | 12-50 | 127/203 | 5/6/8/10/16/20/25 | |

| 400 | 3.5-50 | 127/203 | 5/6/8/10/16/20/25 | |

| 450/500/600/700/750 | 12-60 | 203/304.8/305 | 5/6/8/10/12/15 | |

| 800/850/900 | 18-50 | 132/304.8/305 | 5/6/8/10/12/15 |

Ideal for grinding alloy blades, including milling cutters, drill bits, spade bits, step reamers, gravers, and more.

| Outer diameter | Overall thickness | Arbor hole diameter | Arbor hole width | Abrasive width | Abrasive thickness | Wheel angle | |

| 50 | 10/12 | 10 | Customized | 2/3 | 2/3 | 40° | |

| 75 | 10/12/15 | 10/19.05/20 | Customized | 2/3 | 2/3 | 30°/45° | |

| 90 | 10/12/15 | 10/19.05/20 | Customized | 3/5 | 3 | 45° | |

| 100 | 12/15 | 19.05/20/31.75/32 | Customized | 3/5 | 3 | 45° | |

| 125 | 15/16/18 | 19.05/20/31.75/32 | Customized | 5/6/8 | 3/4 | 25°/45° | |

| 150 | 16/18 | 31.75/32 | Customized | 5/6/8 | 3/4 | 45° | |

| 175 | 18/20 | 31.75/32 | Customized | 5/6/8 | 3/4/5 | 45° | |

| 200 | 20/25 | 31.75/32/75 | Customized | 5/8/10 | 3/4/5 | 45° | |

| 250 | 20/25/30 | 75/127 | Customized | 5/8/10 | 5/6/8 | 45° |

Note: Other specifications can be customized upon request!

Related Product

Related products

Send Message

Most Recent

More

Other Products

Videos