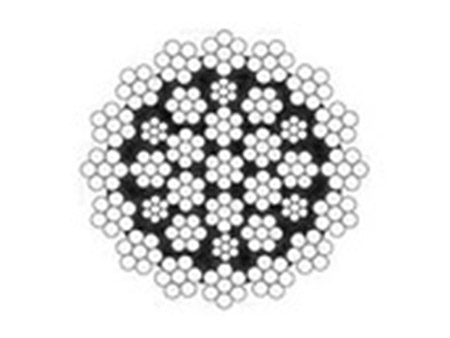

35WX7 Wire Rope, Non-Rotation

Compared to 18*7 and 19*7 series, wire rope-35WX7 non-rotation not only has better resistance to rotation, but also comes with better flexibility. Its density is l5% higher than that of either 18*7 or 19*7 series. In the market, both 35W*7 and 18*7 series are highly demanded. 35WX7 non-rotating steel rope requires higher cost than 18*7 series does.

Wire rope-35WX7 non-rotation is two-time formed. You need entwist 16 small strands, and then entwist them with 19W*7 steel core. Our rotation resistant steel-cored wire rope is specially handled for minimizing the inner stress.

Product Specifications

Structure: 35W*7

Diameter: 6~50mm

Surface Treatment: Hot galvanizing, electrogalvanizing, polishing

Tensile Strength: 1570mpa, 1670mpa, 1770mpa, 1870mpa, 1960mpa

Standards: GB, JIS, RR-W, API, or as requested by clients

Application: Cranes, elevator, and general engineering

Features: Good abrasion resistance and long fatigue life

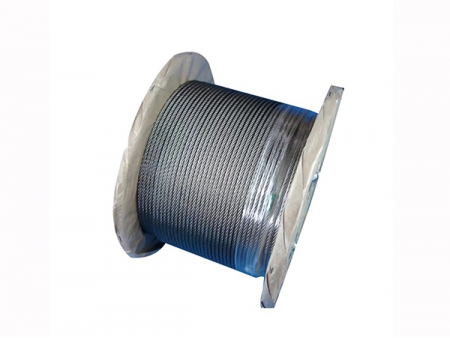

Package: Wooden spool

| Diameter (mm) | Approximate Weight (kg/100m) | Nominal Tensile Strength | ||||||||||||

| 1570 | 1670 | 1770 | 1870 | 1960 | 2160 | |||||||||

| Minimum Breaking Force (KN) | ||||||||||||||

| Fiber Core | Steel Core | Fiber Core | Steel Core | Fiber Core | Steel Core | Fiber Core | Steel Core | Fiber Core | Steel Core | Fiber Core | Steel Core | Fiber Core | Steel Core | |

| 6 | 14.0 | 15.5 | 17.5 | 18.5 | 18.6 | 19.7 | 19.8 | 20.9 | 20.9 | 22.1 | 21.9 | 23.1 | 24.1 | 25.5 |

| 7 | 19.1 | 21.1 | 23.8 | 25.2 | 25.4 | 26.8 | 26.9 | 28.4 | 28.4 | 30.1 | 29.8 | 31.5 | 32.8 | 34.7 |

| 8 | 25.0 | 27.5 | 31.1 | 33.0 | 33.1 | 35.1 | 35.1 | 37.2 | 37.1 | 39.3 | 38.9 | 41.1 | 42.9 | 45.3 |

| 9 | 31.60 | 34.8 | 39.4 | 41.7 | 41.9 | 44.4 | 44.4 | 47.0 | 47.0 | 49.7 | 49.2 | 52.1 | 54.2 | 57.4 |

| 10 | 39.0 | 43.0 | 48.7 | 51.5 | 51.8 | 54.8 | 54.8 | 58.1 | 58.0 | 61.3 | 60.8 | 64.3 | 67.0 | 70.8 |

| 11 | 47.20 | 52.0 | 58.9 | 62.3 | 62.6 | 66.3 | 66.3 | 70.2 | 70.1 | 74.2 | 73.5 | 77.8 | 81.0 | 85.7 |

| 12 | 56.20 | 61.9 | 70.1 | 74.2 | 74.5 | 78.9 | 78.9 | 83.6 | 83.6 | 88.3 | 87.5 | 92.6 | 96.4 | 102 |

| 13 | 65.90 | 72.7 | 82.3 | 87.0 | 87.5 | 92.6 | 92.6 | 98.1 | 98.1 | 104 | 103 | 109 | 113 | 120 |

| 14 | 76.40 | 84.3 | 95.4 | 101 | 101 | 107 | 107 | 114 | 114 | 120 | 119 | 126 | 131 | 139 |

| 16 | 99.80 | 110 | 125 | 132 | 133 | 140 | 140 | 149 | 149 | 157 | 156 | 165 | 171 | 181 |

| 18 | 126 | 139 | 158 | 167 | 168 | 177 | 177 | 188 | 188 | 199 | 197 | 208 | 217 | 230 |

| 20 | 156 | 172 | 195 | 206 | 207 | 219 | 219 | 232 | 232 | 245 | 243 | 257 | 268 | 283 |

| 22 | 189 | 208 | 236 | 249 | 251 | 265 | 265 | 281 | 281 | 297 | 294 | 311 | 324 | 343 |

| 24 | 225 | 248 | 280 | 297 | 298 | 316 | 316 | 334 | 334 | 353 | 350 | 370 | 386 | 408 |

| 26 | 264 | 291 | 329 | 348 | 350 | 370 | 370 | 392 | 392 | 415 | 411 | 435 | 453 | 479 |

| 28 | 306 | 337 | 382 | 404 | 406 | 429 | 429 | 455 | 454 | 481 | 476 | 504 | 525 | 555 |

| 30 | 351 | 387 | 438 | 463 | 466 | 493 | 493 | 523 | 522 | 552 | 547 | 579 | 603 | 638 |

| 32 | 399 | 440 | 498 | 527 | 530 | 561 | 561 | 594 | 594 | 628 | 622 | 658 | 686 | 725 |

| 34 | 451 | 497 | 563 | 595 | 598 | 633 | 633 | 671 | 671 | 709 | 702 | 743 | 774 | 819 |

| 36 | 505 | 557 | 631 | 667 | 671 | 710 | 710 | 752 | 751 | 795 | 787 | 833 | 868 | 918 |

| 38 | 563 | 621 | 703 | 744 | 748 | 791 | 791 | 838 | 837 | 886 | 877 | 928 | 967 | 1020 |

| 40 | 624 | 688 | 779 | 824 | 828 | 876 | 876 | 929 | 928 | 981 | 972 | 1030 | 1070 | 1130 |

| 42 | 688 | 759 | 859 | 908 | 913 | 966 | 966 | 1020 | 1020 | 1080 | 1070 | 1130 | 1180 | 1250 |

| 44 | 755 | 832 | 942 | 997 | 1000 | 1060 | 1060 | 1120 | 1120 | 1190 | 1180 | 1240 | 1300 | 1370 |

Instruction

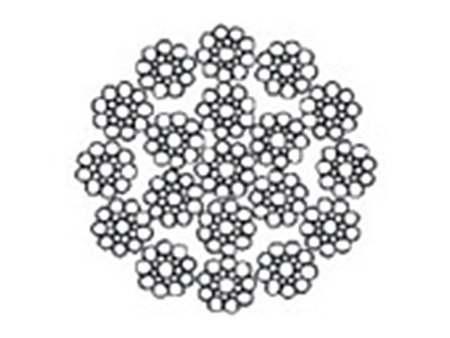

The non-rotating steel wire rope is also called multi-strand wire rope. Gaosheng Company specially produces and sales many a wire rope. We have 35W*7 series, 18*7 series, 19*7 series, 18*19S series, and 24W*7 series.

All those series, twisted in the same or different direction, have been galvanizing and polishing treated. If you need the wire rope of higher breaking strength or better abrasion resistance, the product can be processed with different surface treatments, for instance, lubrication, plastic dipping, etc.

Application

This non-rotating steel wire rope is suited for kinds of hoisting and dragging equipment. It can be applied in the condition of impact load, as well as in the heated or squeezed condition. The steel cored wire rope of different diameter is suitable for different cranes. A wire rope with the diameter of 12mm-28mm is suitable for truck crane, portal crane, electric hoist crane, etc.

- During the transit, please handle it with care for preventing the outer packing materials from being collided.

- Avoid contact with moisture and rainwater. The non-rotating steel wire rope should be placed in the dry, ventilated indoor environment.

- Mind the direction of wire pay-off and take-up, so as to avoid additional stress.

- In the workplace, pay attention to the threading direction, thus to avert the additional stress and wire bending.