Capability

At present, the company owns 420 sets of production equipment, including 26 sets of imported equipment, such as four continuous vulcanization production lines of Germany TROESTER, America ROYLE and Finland NOKIA Φ65+Φ115/Φ90 for three-layer coextrusion and two-layer coextrusion, and Italy SAMP’s 16 wire drawing machine, Canada CEECO’s 350 interlocking armouring machine, Spain, Austria’s Graery HK80 film wrapping machine, Germany’s LUKAS sintering production line. Especially the double twisting machine produced by Caballe of Spain is the first advanced equipment used in cable conductor production in China. The HV XLPE insulated power cable production line produced by Finland’s Nokia adopts three-layer coextrusion continuous vulcanization catenary production, and is equipped with the advanced automatic on-line polarimeter from Germany’s SIKORA, controlling the tolerance within 0.05mm which reaches the international leading level. In addition to imported equipment, the company also has a number of domestic advanced equipment such as high-frequency high-voltage electron irradiation accelerator, mixed rubber automatic feeder and 315 rigid bobbin stranding machine. It provides a powerful guarantee for the development of new products, improvement of product quality and expansion of market share. During the years of production, the Company has trained a group of professional production teams which provides an eternal driving force towards the internationalization.

TROESTER Triple Extrusion Line for MV Rubber Cables

TROESTER Triple Extrusion Line for MV Rubber Cables Continuous vulcanization production lines

Continuous vulcanization production lines SAMP 16 Threads Drawing Machine for Flexible Conductor

SAMP 16 Threads Drawing Machine for Flexible Conductor production

production Cable reel roller

Cable reel roller production

production

As a national accredited laboratory, Hebei Huatong Wires and Cables Group Co.,Ltd. not only has advanced production lines, it also is equipped with the leading domestic testing facilities. The combustion laboratory can conduct combustion test for bunched cables, fire resistant combustion test, mine cable load combustion test, vertical combustion test for single cable, which fully meets the combustion test requirements of IEC, BS and national standards. The oxygen index, halogen content, smoke density and carbon black content are determined accurately. Moreover, the Company is also equipped with a number of sophisticated testing equipment, such as Swiss AESA’s DC resistance measuring instrument, American Monsanto vulcanizer and the 77.5kV/750 kVA high voltage partial discharge detection device produced by American Hipo Company for factory inspection of incoming materials and products with the inspection rate of 100%. Well-trained and highly-qualified staff strictly control the process and use modern scientific and technological means to refine management, elaborate production and inspection.

On-line tester for insulation

On-line tester for insulation EDX-LE Facility for RoHs

EDX-LE Facility for RoHs RES TEST 100 Bridge

RES TEST 100 Bridge

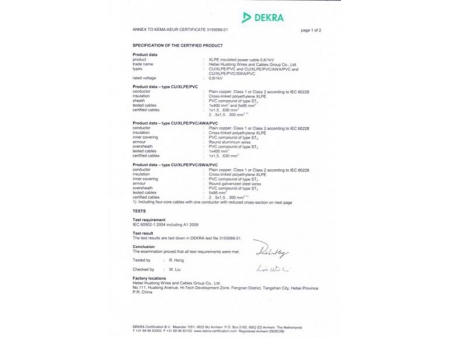

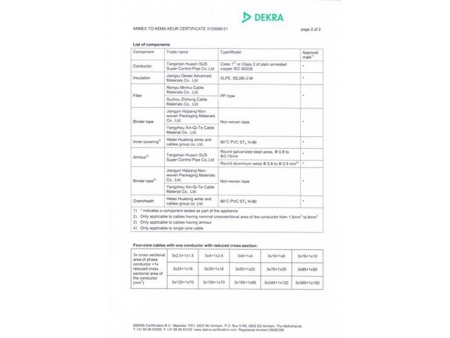

We have obtained the following certifications: ISO 9001, ISO 14001, OHSAS 18001, China Compulsory Certification (CCC), Safety Certificate of Approval for Mining Products, China Production Licence of Industrial Products, China Scientific Research and Production Licensing of Arms and Equipment, International Railway Industry Standard (IRIS). Our certificates are offered by different certification bodies, including Norway DNV, France BV, China CCS, America ABS, UK LR, Japan NK, South Korea KR, etc.