Vacuum Sterilizer

The WG vacuum sterilizer uses saturated steam as the sterilization medium. It utilizes the physical properties of steam in order to release large quantities of latent heat and moisture to ensure objects are sterilized in a high temperature and humidity environment. After the set constant temperature period, the main component of the bacteria-protein coagulates and is killed. Through the use of a pulsating vacuum exhaust method, air influence on the temperature is eliminated, thus, vacuum dehumidification works with the drying process to dry the now sterilized products.

This vacuum sterilizer is suitable for applications in pharmaceutical, medical, scientific research and other industries that require high-temperature sterilization, cooling and drying treatments on objects like biological products, medical appliances, sterile clothing, apparatus, containers, culture mediums and more.

Sterilizer body: horizontal and rectangular double-layer structure. The inner tank is made of SUS30408 or SUS31608 stainless steel, and the external decorative panel uses a SUS304 stainless steel wire drawing board. The door structure includes a motor-drive door and sliding door. The pneumatic seal and double-door interlock are also compliant with the GSSD specification requirements.

Sterilizer control system: Siemens PLC and Siemens touch screen.

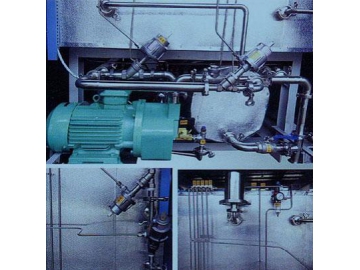

Sterilizer pipeline system: Germany GEMU pneumatic angle seat valve, water ring vacuum pump, 0.22um high-efficiency and sterile medical filter. The pipeline uses a clamp quick joint, while the piping and accessories are all sanitary.

- The sterilizer software design and manufacturing are conducted according to strict sterilization product technical requirements.

- Operation authority management has a strict managerial class, including a 3 level management system of the manager, maintainer and operator.

- The interlock between the manual program, automatic program and sterilizer door opening makes it impossible to open or close the sealed door when the program is running.

- All alarms and process data can be recorded and printed.

- If the temperature of the inner chamber exceeds safe levels, it is impossible to open the door, thus guaranteeing the safety.

- If the inner chamber pressure is greater than set safety pressure levels, the door will not open, also ensuring safety.

- The operation of this sterilization equipment takes emergency operations into full consideration for abnormal working conditions. This is divided into 4 levels.

| Equipment specifications | Equipment capacity | Internal chamber size (L× W× H) | Overall size (L× W× H) | Steam pressure and consumption | Water pressure and consumption | Power supply | Equipment Net weight | Design pressure | Design temperature | |

| WG-0.25JS (D) | 0.25M³ | 800×600×600mm | 1100×1300×1700mm | 0.4-0.8Mpa 15KG | 0.15-0.3Mpa 35KG | 2+24kw | 900Kg | 0.25Mpa | 139℃ | |

| WG-0.36JS (D) | 0.36M³ | 1000×600×600mm | 1300×1300×1700mm | 0.4-0.8Mpa 20KG | 0.15-0.3Mpa 40KG | 2+24KW | 1000Kg | | ||

| WG-0.6JS (D) | 0.6M³ | 1200×610×910mm | 1500×1350×1950mm | 0.4-0.8Mpa 30KG | 0.15-0.3Mpa 45KG | 3+36KW | 1400Kg | | ||

| WG-0.8JS (D) | 0.8M³ | 1500×610×910mm | 1800×1350×1950mm | 0.4-0.8Mpa 40KG | 0.15-0.3Mpa 50KG | 3KW | 1600Kg | | ||

| WG-1.2JS (D) | 1.2M³ | 1500×680×1180mm | 1790×1450×1950mm | 0.4-0.8Mpa 48KG | 0.15-0.3Mpa 55KG | 4KW | 1800Kg | | ||

| WG-1.5JS (D) | 1.5M³ | 1900×680×1180mm | 2190×1450×1950mm | 0.4-0.8Mpa 55KG | 0.15-0.3Mpa 60KG | 4KW | 2000Kg | | ||

| WG-2.0JS (D) | 2.0M³ | 1700×1000×1200mm | 2000×1850×2000mm | 0.4-0.8Mpa 65KG | 0.15-0.3Mpa 65KG | 4.5KW | 2500Kg | |