Cable Sheath Line

Continuous Extrusion Cladding for Cable

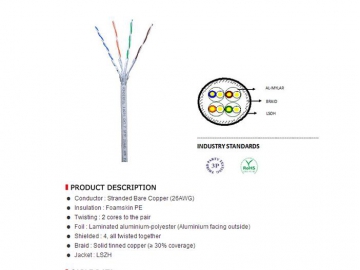

Continuous extrusion cladding technology is continuous extrusion tangential cladding and it's divided into two processes: direct cladding and indirect cladding. These two processes, equipped with different dies and corresponding equipment, can produce different cladding products according to different demands.

Soft cladding technology (for OPGW&CATV) adopts continuous extrusion indirect cladding technology to continuously extrude aluminum into aluminum tubes which indirectly clad on the exteriors of soft core wires. Then by drawing, aluminum tubes will be tightly clad on the surface of soft core wires. The core wires won't be scalded due to high temperature. By adopting similar process, carbon fiber core rod or BTLY fire-resistant cable can be clad with aluminum protective sleeve.

| Machine Type | Tangential Cladding Type | |||

| Diameter of Extrusion Wheel | Φ350mm | |||

| Max. Rotation Speed | 16.7 RPM | |||

| Power of Main Motor | 200kW/1500 RPM | |||

| Feedstock Diameter | 2×Φ9.5mm | |||

| Feedstock Diameter Tolerance | ±0.2mm | |||

| Max. Tensile Strength | ≤95MPa | |||

| Material: Clean Continuous Casting and Rolling Aluminum Rod | ||||

| Cladding Machine | -9 | -12 | -13 | -15 |

| Outer Diameter of Insulation Layer | 9.00mm | 11.43mm | 13.03mm | 14.35mm |

| Outer Diameter of Conductor | 10.30mm | 12.70mm | 14.30mm | 15.88mm |

| Maximum Line Velocity | 80m/min | |||

| Flash Amount | 5% | |||

| Power Supply | 3Phase, 50Hz, 380V, 350KVA | |||

| Compressed Air (no oil or water) | 0.7MPa, 5m3/min | |||

| External Circulating Cooling Water | 0.4MPa, 50tons/h | |||

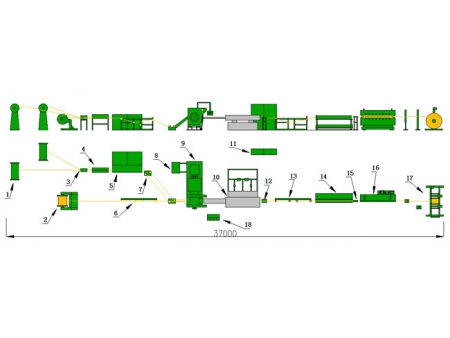

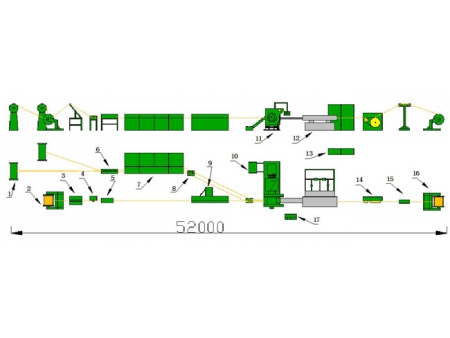

| Workshop Dimension | 55m ×12m×6m | |||

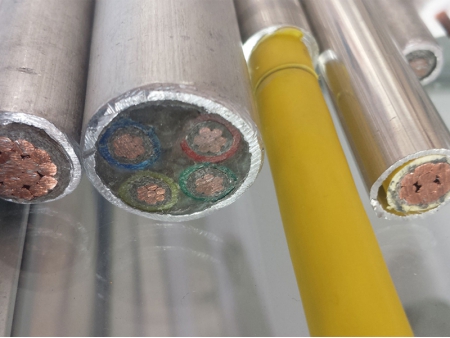

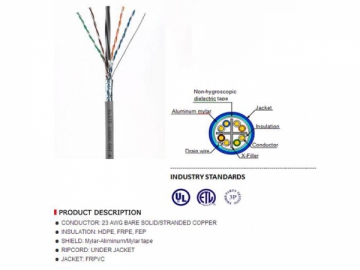

- The aluminum clad cable extrusion line refers to a special type of cladding machine to continuously extrude the aluminum rod feedstock into aluminum sheath. Then, the aluminum sheath is coated on the outer layer of the cable which is finally processed into the final product.

- With seamless cladding method, the continuous rotary extrusion machine is free from the seam quality problem. Meanwhile, the sheath has excellent sealing ability.

- Our continuous extrusion equipment has no heating procedure, thus saving space, equipment and energy.

- The aluminum clad cable extrusion line can be used to manufacture cable, fiber sheath CATV coaxial-cable, fire resistant jacketed cable for television signal and railway communication signal transmission purposes.

Aluminum Extrusion Processing, Continuous Rotary Extrusion Process, Aluminum Extrusion Presses, Continuous Extrusion Equipment Manufacturer