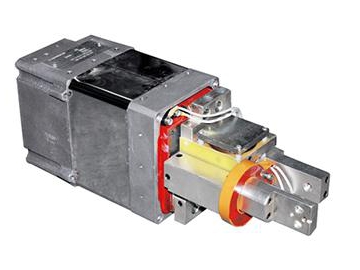

Mid Frequency Inverter, Resistance Welding Control

Request a Quote

The mid frequency inverter can increase the frequency of a resistance transformer from 50/60Hz to 1000Hz to decrease the weight of its iron core, reduce secondary inductive losses and control energy and operating costs. It can be paired with automatic electrode-holders to form a portable and lightweight welding equipment set with excellent performance.

Features

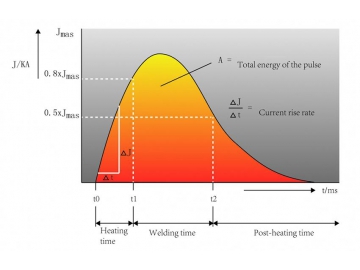

- The amount of splashing is largely decreased for a high quality weld and a clean, safe, and comfortable welding environment

- Accurate control of welding parameters in 1 millisecond for the consistent welding results of multilayer steel plate, thick steel plate, high strength steel sheet and aluminum alloy

- Basic building blocks of an inverter and in-process monitoring of weld quality and data monitoring

- Stable welding control system to prevent weld defects

- Three-phase electric power system and medium frequency welding

- No capacitance compensation cabinet

- Small volume and light weight. Compatible with suspension welders

- HMI operator interface for easy operation

Parameter

| Model | EX-400 | EX-720 | EX-1100 | EX-1980 |

| Input voltage | Single phase/three phase 220/380V+-15% | |||

| Rated frequency | 50/60HZ | |||

| Transformer voltage | DC500V | |||

| Working frequency | 1KHZ-8KHZ | 1KHZ-4KHZ | 1KHZ-2KHZ | 1KHZ-2KHZ |

| Current pattern | 00MF/DC | |||

| Maximum output current20% | 400A | 720A | 1100A | 1980A |

| Continuous output current100% | 120A | 230A | 400A | 630A |

| Control pattern | KSR/KUR/KST | |||

| Current feedback pattern | primary/secondary | |||

| Operating display | text/HMI/PC | |||

| Data range(group) | 7 | 256 | 64K | 64K |

| Controlled equipment | Spot Welder/Projection welder/Seam Welder3T/Seam Welder1T/Suspension welder等 | |||

| Communication station number | 43472 | 1-255 | 1-255 | 1-255 |

| Protocol | 9600,7,E,1 | |||

| Communication form | RS485/RS232 | |||

| Control process | +-1% | |||

Related products

Send Message

Most Recent

More

Other Products

Videos