Centrifugal Disc Finishing Machine

Request a Quote

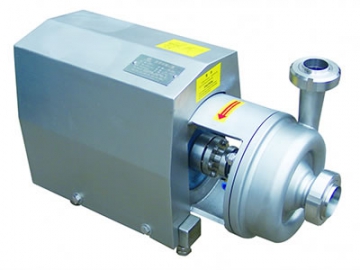

The centrifugal disc finishing machine is suitable for the finishing of workpieces with big burrs, thick oxide layer or irregular shapes. The disc finishing machine features uniform grinding force and can overcome difficulties that sheet or thread components are easy to deform or overlap.

ApplicationThe centrifugal finishing machine can be utilized for deburring, radiusing, rust removal, polishing and so on, widely used for the stamping, machining, casting, heat treating of metal, plastic, porcelain components in various industries.

Parameters| Model | Disc Diameter | Loading Capacity | Speed | Motor Power | |

| CL-W50L | 500mm | 50L | 50-250r/min | 2.2kw | |

| CL-W120L | 700mm | 120L | 40-200r/min | 5.5kw |

- Low noise, no vibration and no finishing media splashing improve the working conditions.

- Speed of the turnplate can stepless speed change from 0 to 250 r/min.

- The fixed groove and the turnplate use the PU lining, featuring high strength, good wear resistance and long working life.

- Both the turnplate and the fixed barrel are aluminum alloy, which is lightweight and wear resistant. External spraying plastics brings qualified acid resistance, ageing resistance and corrosion resistance.

- A digital readout timer is added to provide easier operations and can check the finishing condition at any time.

- The grinding groove is connected to the motor. Pushing the button, the groove will automatically turn in 90 degrees to discharge the abrasive and workpiece, saving much unnecessary time and labor work.

Related products

Send Message

Most Recent

More

Other Products

Videos